Radial rotary conveying mechanism for moving table of special-shaped steel rail forging and pressing production press machine

A conveying mechanism and press technology, applied in forging/pressing/hammering machinery, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problems of unfavorable and rapid conversion, large investment in presses, time-consuming die changing and hoisting, etc. , to achieve the effect of reducing expenditure costs, accurate and reliable control, and saving site space

Pending Publication Date: 2021-10-12

CHINA RAILWAY BAOQIAO (NANJING) CO LTD +1

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the prior art, limited by site space and investment funds, such as the technical scheme of a press equipped with double movable worktables disclosed in CN103085314B, a mobile control device and a control method as an example, although the use of a double movable table press To a certain extent, it solves the problems of huge investment in presses and time-consuming lifting of molds

However, the double-sliding table press still cannot meet the needs o

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

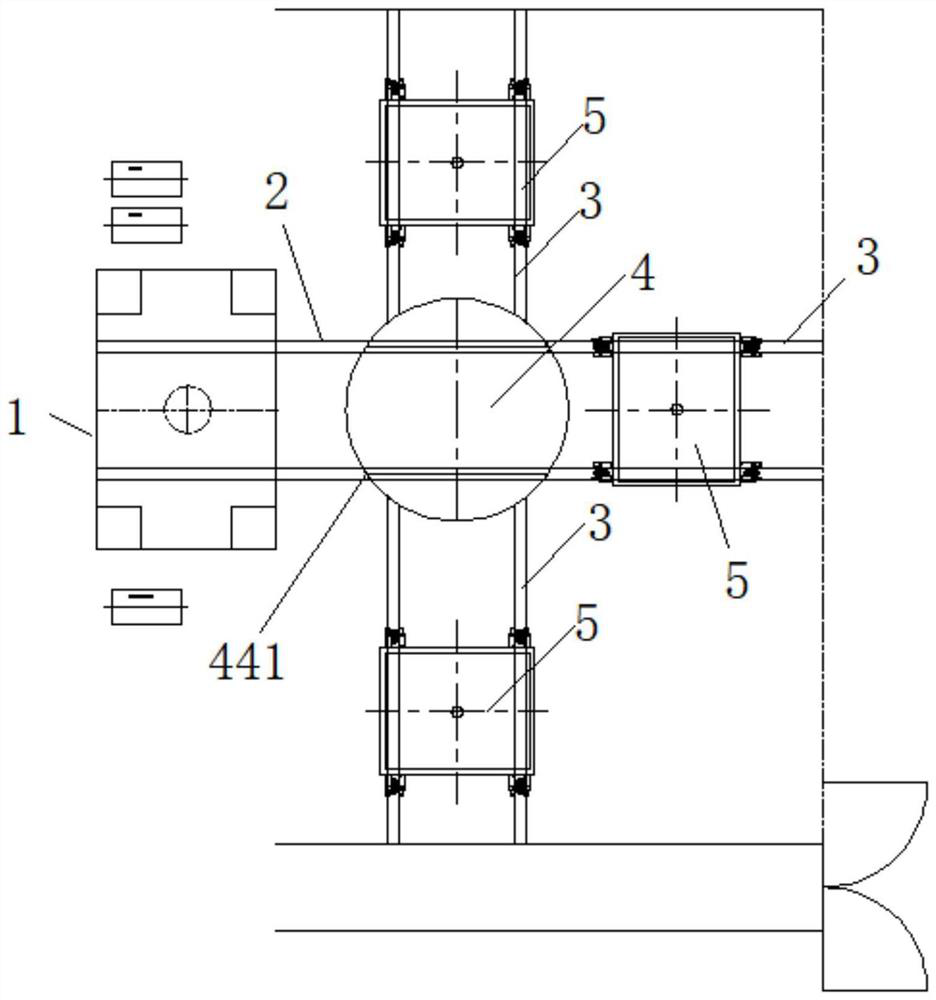

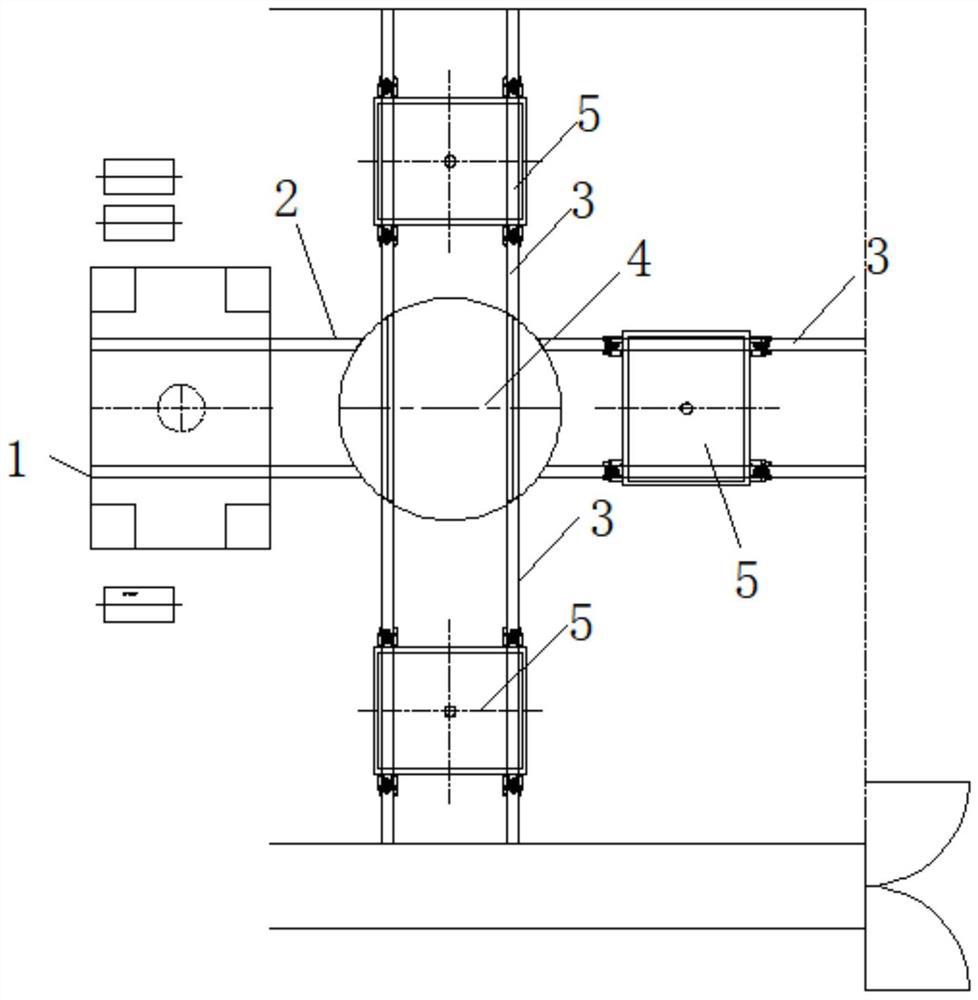

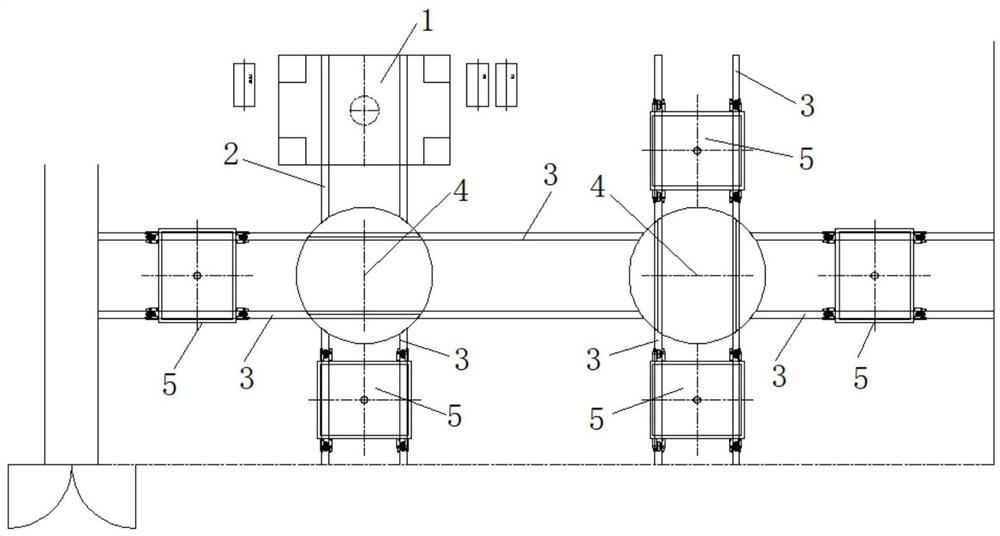

The invention provides a radial rotary conveying mechanism for a moving table of a special-shaped steel rail forging and pressing production press machine, which comprises a servo motor, a radial horizontal rotary speed-reducing transmission mechanism, a rail bearing mounting base and a public rail; public rails which are parallel at intervals are fixedly mounted on the upper end surface of the rail bearing mounting base; the servo motor is fixedly mounted on the lower end surface of the track bearing mounting base; and the servo motor drives the rail bearing mounting base to perform fixed-axis radial rotation through a radial horizontal rotation speed reduction transmission mechanism. According to the radial rotary conveying mechanism for the moving table of the special-shaped steel rail forging and pressing production press machine provided by the invention, on-off, connection and conversion operations between at least more than three moving table rails and a press can be realized, and the design of a multi-moving table rail system can be simplified to the greatest extent; the radial rotary conveying mechanism is economical, practical, reliable and efficient; and particularly, the requirements for large-tonnage, anti-bumping and high-precision butt-joint bearing switching conveying are met.

Description

technical field [0001] The invention belongs to the technical field of special equipment for transporting or fixing the position of a combined mold for operation and transportation, and specifically relates to a radial rotary conveying mechanism for a special-shaped rail forging production press. Background technique [0002] The mobile table, that is, the mobile table, plays an extremely important role in the mold change of the mechanical press. The number of mobile worktables plays a leading role in improving the efficiency of the press. In the prior art, limited by site space and investment funds, such as the technical scheme of a press equipped with double movable worktables disclosed in CN103085314B, a mobile control device and a control method as an example, although the use of a double movable table press To a certain extent, it solves the problems of huge investment in presses and time-consuming lifting of dies. However, the double-sliding table press still cannot m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21J13/02B21J13/04

CPCB21J13/02B21J13/025B21J13/04

Inventor 赵小军刘江吴钟敏戴烨国

Owner CHINA RAILWAY BAOQIAO (NANJING) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com