Correction method for output value of flow control model of high-pressure pump of oil rail

A model output and flow control technology, applied in the direction of fuel injection pumps, charging systems, fuel injection devices, etc., can solve problems such as abnormal fuel injection, rail pressure runaway, flushing, etc., to avoid overshoot and control accurately Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0050] It should be noted that the idling point referred to herein refers to the operating point at which the engine is in an idle power state, and the rated point refers to the operating point at which the engine is in a rated power state.

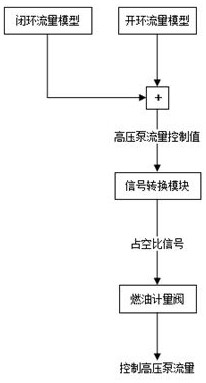

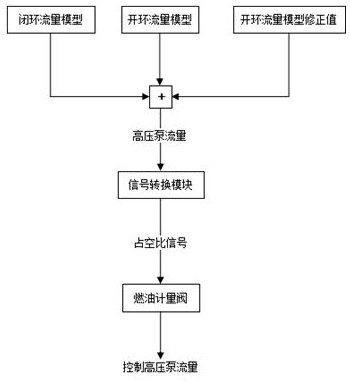

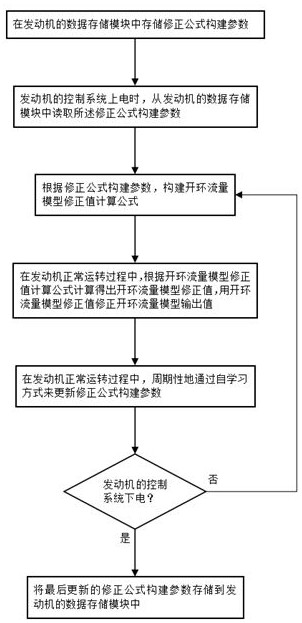

[0051] see figure 2 and image 3 , this embodiment provides a method for correcting the output value of the fuel rail high-pressure pump flow control model. The correction method avoids the influence of the deviation of the output current of the fuel metering valve on the flow control accuracy of the fuel rail high-pressure pump. The flow control of the high-pressure pump is more precise, thereby avoiding the situation that the rail pressure of the fuel rail is overregulated.

[0052] see image 3 , the correction method of this embodiment includes the following steps 1 to 6.

[0053] Step 1, pre-stored in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com