Shell-and-tube heat exchanger

A shell-and-tube heat exchanger and heat exchange tube bundle technology, which is applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. Large, the rigidity and toughness of the shell cannot be taken into account, etc., to solve the problems of large expansion deformation and deformation difference, low manufacturing and installation cost, and excellent heat exchange effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

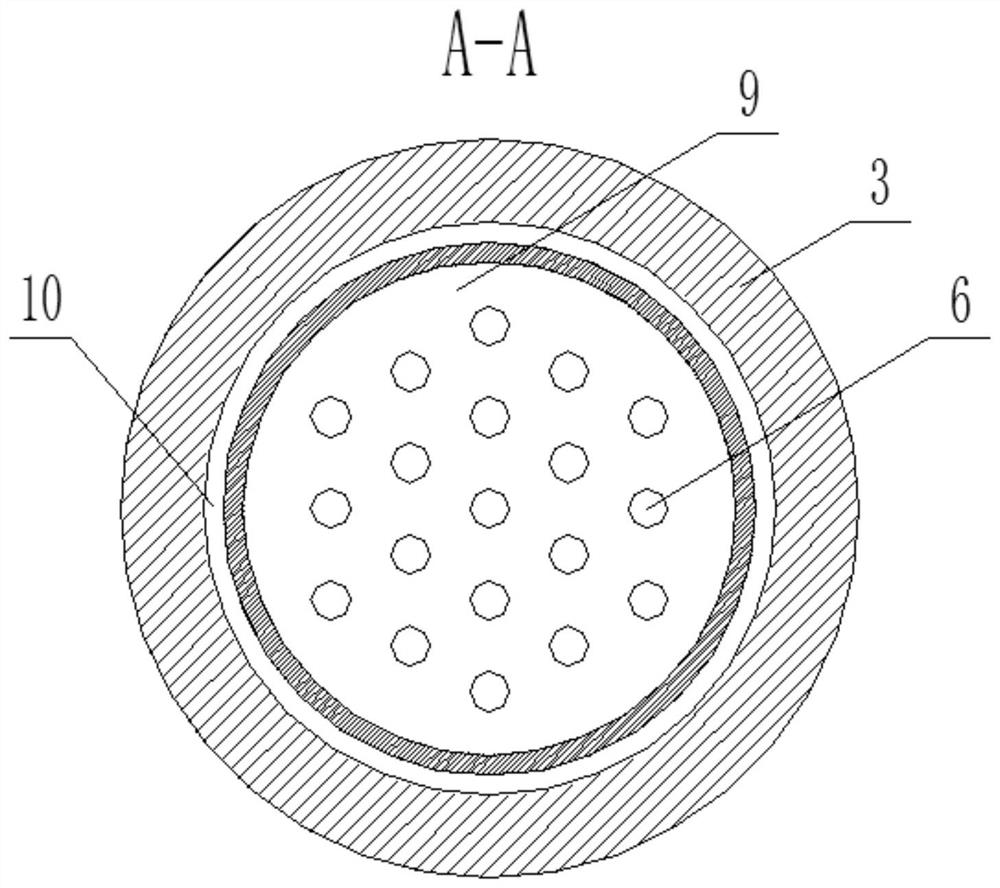

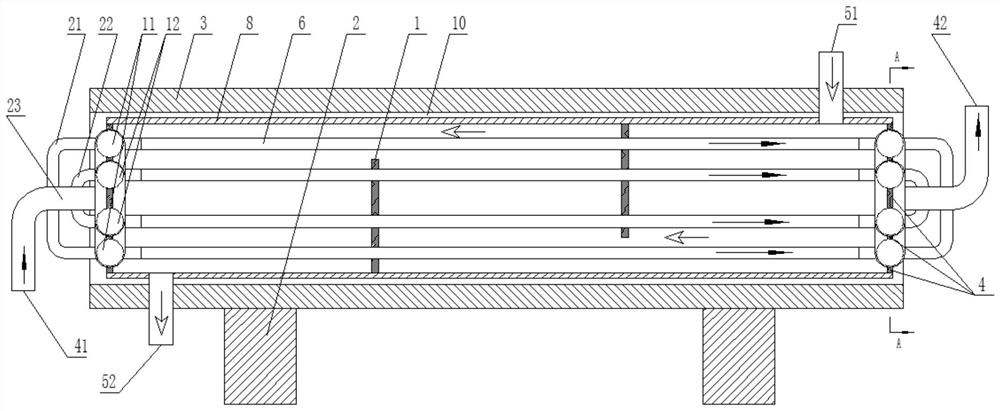

[0034] see figure 1 and figure 2 , a shell-and-tube heat exchanger, including an outer shell 3 and an inner shell 8 with the same length, the outer shell 3 is essentially a cylinder with both ends open, and the cylinder can be an integral structure or a segmented structure, It can also be an axially split structure. The outer shell 3 is provided with a support 2, and the inner cavity of the inner shell 8 is provided with a heat exchange tube bundle 6 and a baffle plate 1. All the heat exchange tube bundles 6 in the same shell are evenly arranged. The heat tube bundle 6 runs through the baffle plate 1, and the inner cavity of the heat exchange tube bundle 6 is used as the circulation channel of the heat exchange medium A, and baffles are respectively arranged at both ends of the heat exchange tube bundle 6, and the outer edge of the baffle is fixedly connected to the inner shell 8, and the baffle body 1. The heat exchange tube bundle 6 and the inner shell 8 together form a ci...

Embodiment 2

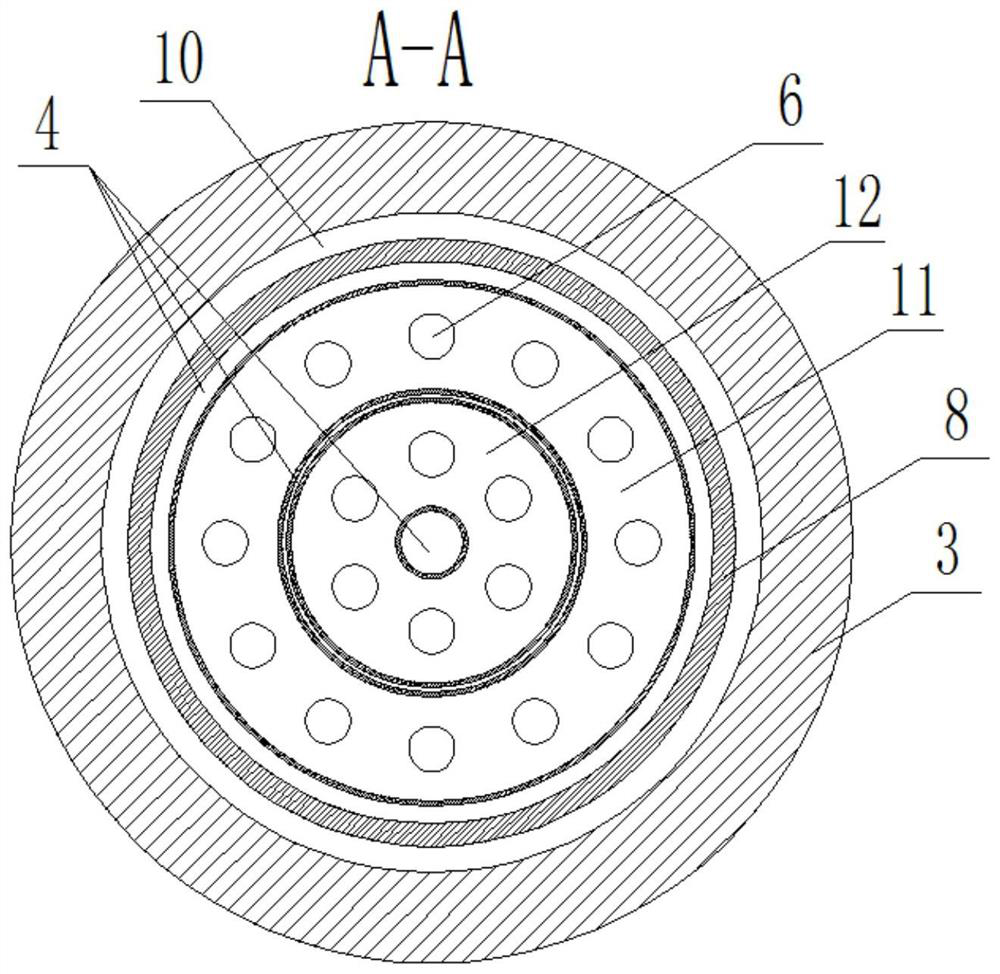

[0042] see image 3 and Figure 4 , a shell-and-tube heat exchanger, including an outer shell 3 and an inner shell 8, the inner cavity of the inner shell 8 is provided with a heat exchange tube bundle 6 and a baffle plate 1, the heat exchange tube bundle 6 runs through the baffle plate 1, and the heat exchange tube bundle 6 The inner cavity is used as the circulation channel of the heat exchange medium A, and baffles are respectively arranged at both ends of the heat exchange tube bundle 6, and the outer edge of the baffle is fixedly connected to the inner shell 8, and is jointly enclosed by the baffle body, the heat exchange tube bundle 6 and the inner shell 8. The circulation channel of the heat exchange medium B: the outer shell 3 with better rigidity is used as the pressure-bearing part and used to support the structural parts in the outer shell 3, and the inner shell 8 with better toughness is used as the sealing member and used to eliminate the stress generated by the he...

Embodiment 3

[0051] see Figure 5 , a shell-and-tube heat exchanger, including an outer shell 3 and an inner shell 8, the inner cavity of the inner shell 8 is provided with a heat exchange tube bundle 6 and a baffle plate 1, the heat exchange tube bundle 6 runs through the baffle plate 1, and the heat exchange tube bundle 6 The inner cavity is used as the circulation channel of the heat exchange medium A, and baffles are respectively arranged at both ends of the heat exchange tube bundle 6, and the outer edge of the baffle is fixedly connected to the inner shell 8, and is jointly enclosed by the baffle body, the heat exchange tube bundle 6 and the inner shell 8. The circulation channel of the heat exchange medium B: the outer shell 3 with better rigidity is used as the pressure-bearing part and used to support the structural parts in the outer shell 3, and the inner shell 8 with better toughness is used as the sealing member and used to eliminate the stress generated by the heat exchange me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com