Paint spraying device for machining

A technology of mechanical processing and treatment device, applied in the direction of spraying device, spraying room, etc., can solve the problems of poor quality of spraying, uneven spraying surface, insufficient spraying, etc., to prevent waste, spray uniformly, and avoid excessive extension speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

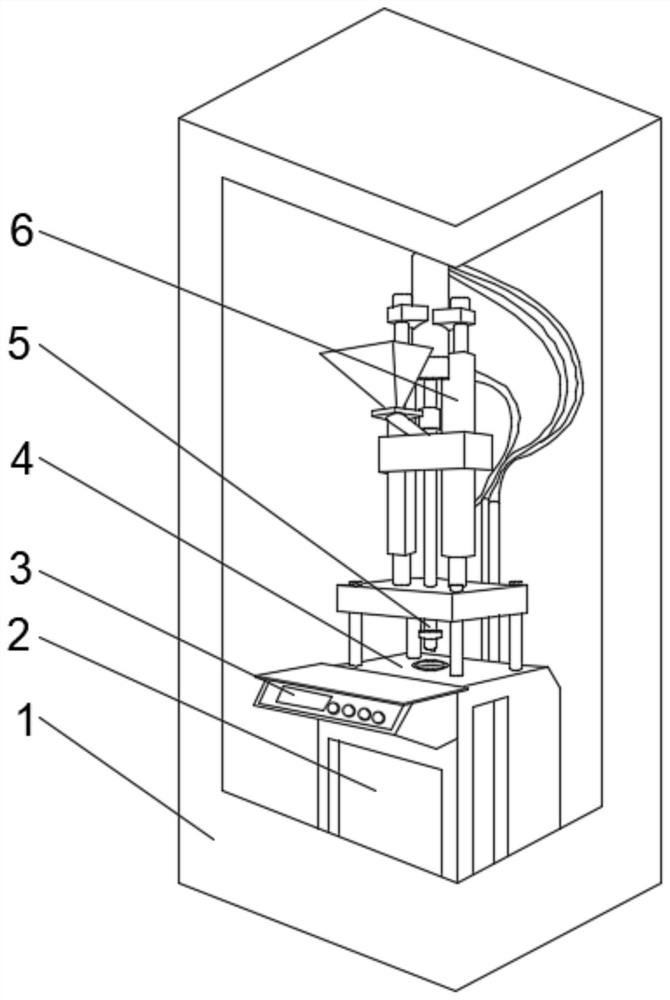

[0033] see Figure 1-2 , the present invention provides a technical solution: a paint spraying device for mechanical processing, comprising an outer frame 1, a base 2 is fixedly connected to the bottom of the inner cavity of the outer frame 1, a control panel 3 is fixedly connected to the top of the front of the base 2, the base The middle position of the top of the base 2 is provided with a processing device 4, the top of the base 2 is located on both sides of the processing device 4 and is fixedly connected with a support frame 6, and the middle position of the bottom of the support frame 6 is provided with a nozzle 5, and the top of the nozzle 5 runs through the support frame 6 and extend to the inside of the support frame 6.

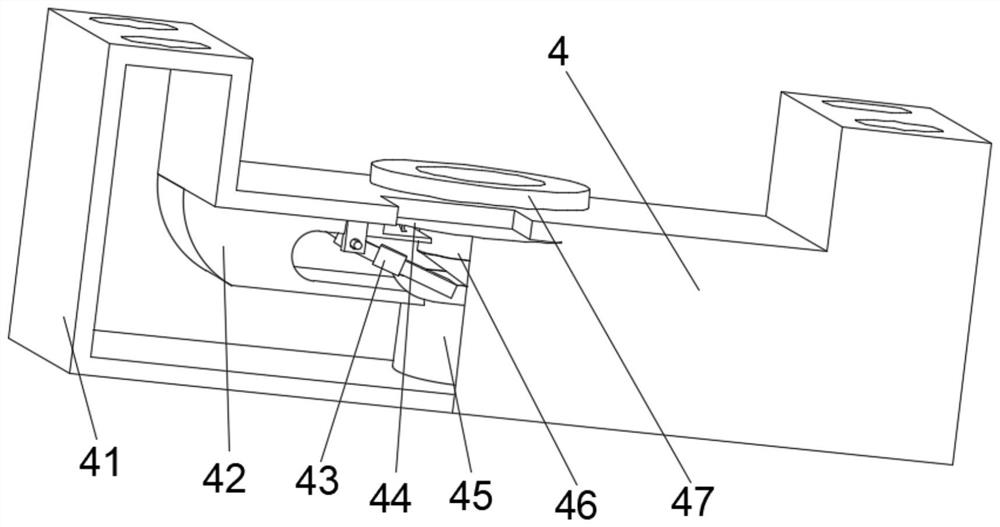

[0034] Wherein, the processing device 4 includes a shell 41, the middle position of the bottom of the inner cavity of the shell 41 is fixedly connected with a fixed seat 45, the top of the outer wall on both sides of the fixed seat 45 is fixedly conn...

Embodiment 2

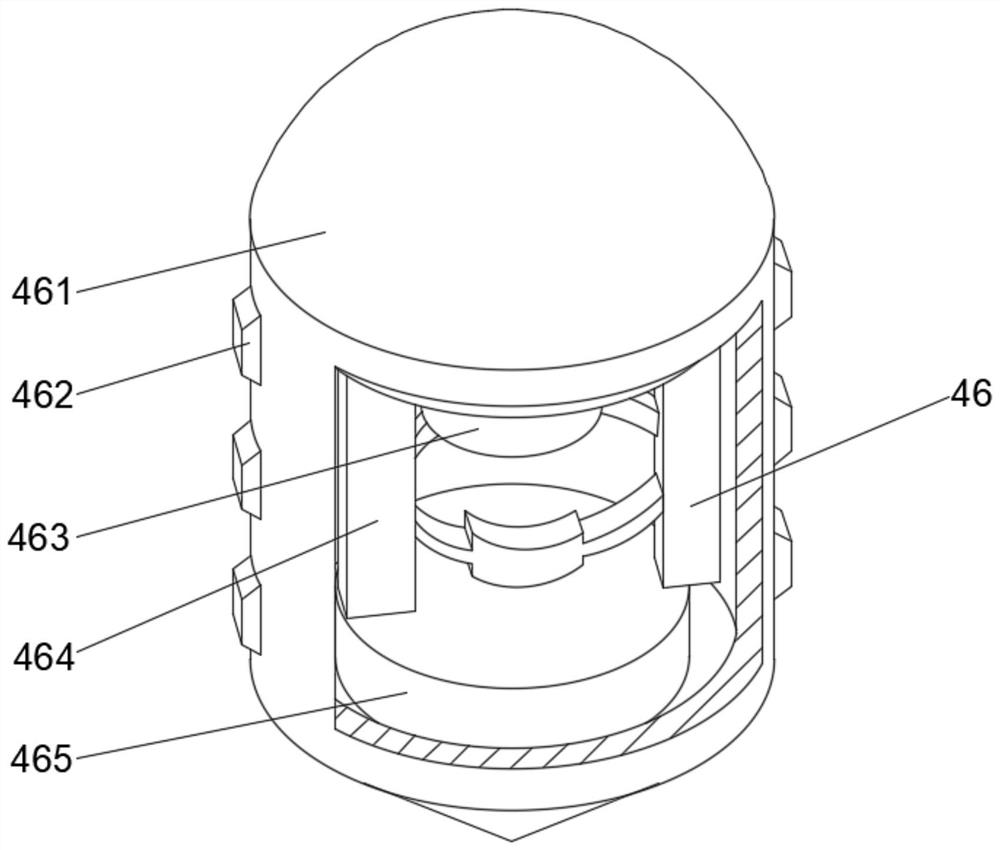

[0037] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: the blocking mechanism 46 includes a blocking block 461, the outer walls of both sides of the blocking block 461 are fixedly connected with contact blocks 462, and the top of the inner cavity of the blocking block 461 is fixedly connected with Support column 463, auxiliary mechanism 464 is fixedly connected to both sides of the bottom of support column 463, the top of auxiliary mechanism 464 runs through support column 463 and extends to the inside of support column 463, and the bottom of auxiliary mechanism 464 is fixedly connected with bottom block 465.

[0038] Wherein, the auxiliary mechanism 464 includes an adjustment block d4, the outer walls of both sides of the adjustment block d4 are provided with guide mechanisms 5, the position of the guide mechanism d5 away from the adjustment block d4 is fixedly connected with an auxiliary plate d2, and the top of the auxiliary...

Embodiment 3

[0041] see Figure 1-5 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the guide mechanism d5 includes a contact-increasing block d51, and the right side of the contact-increasing block d51 is fixedly connected with an upper extension plate d52, and the upper extension plate d52 The right side is provided with a balance weight d53, and the middle part of the right side of the upward extension plate d52 runs through the balance weight d53 and extends to the inside of the balance weight d53. The inner wall is fixedly connected with elastic ball d55.

[0042] When in use, when the device is moved by the extrusion force, the elastic ball d55 has good elasticity and can be dented when it is hit, thereby increasing the friction area of the device, thereby ensuring the smooth progress of the painting work and increasing contact The protrusions on the surface of the board d54 will engage when moving, thereby increasing the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com