Transport box for products packaged by edible packaging film

A transport box and packaging film technology, applied in the field of transport boxes, can solve the problems affecting fruit preservation and tearing of packaging films, and achieve the effect of avoiding fruit shock damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

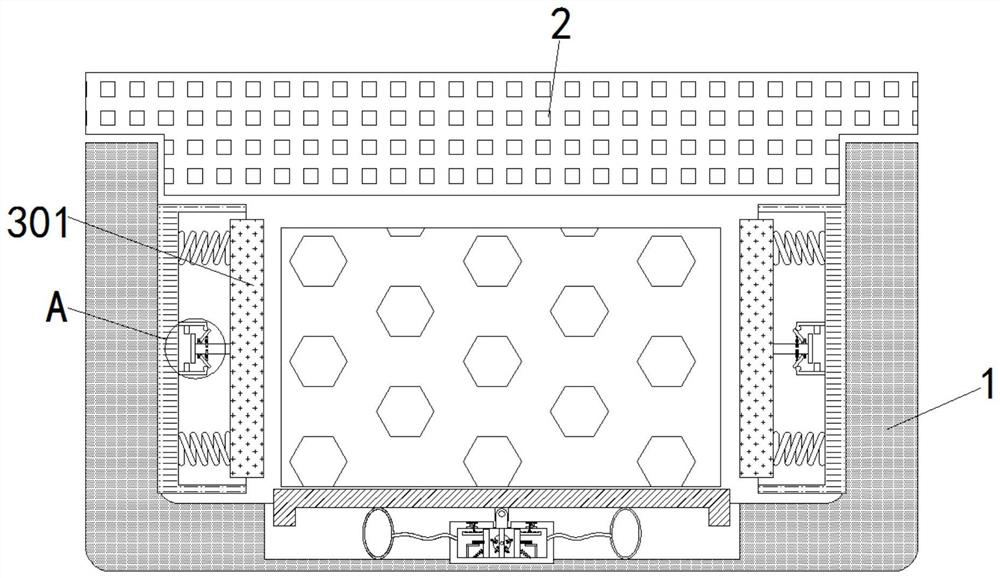

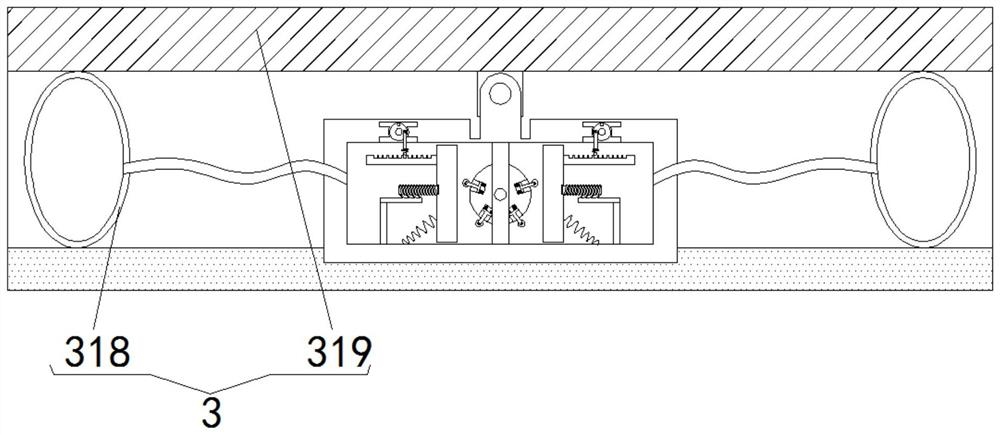

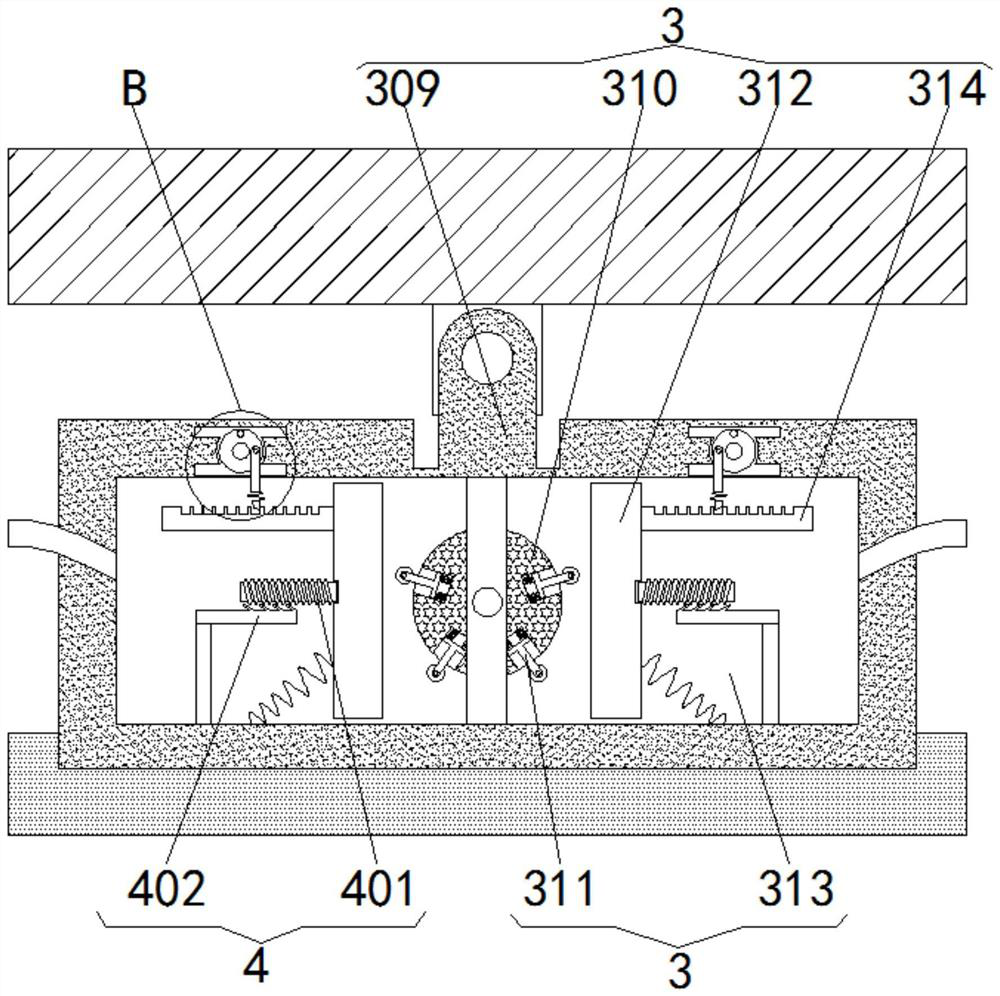

[0025] Example 1: Please refer to Figure 1-5 , a transport box for edible packaging film packaging products, comprising a box body 1, the top of the box body 1 is provided with a box cover 2, the inside of the box body 1 is provided with an anti-scratch mechanism 3, and the interior of the anti-scratch mechanism 3 is fixed An extrusion plate 301 is installed, and the side of the extrusion plate 301 away from the center of the box body 1 is fixedly connected with an extrusion rod 302, and the side of the extrusion rod 302 away from the extrusion plate 301 is fixedly connected with a metal block 307, and the metal block 307 is away from One side of the extruding plate 301 is provided with a conductive plate 308, and the inside of the box body 1 is provided with a holding plate 319, and the bottom of the holding plate 319 is rotatably connected with a support block 309, and the inside of the support block 309 is provided with an inflatable chamber 313 for inflating air. The cham...

Embodiment 2

[0028] Example 2: Please refer to Figure 1-5 , a transport box for edible packaging film packaging products, comprising a box body 1, the top of the box body 1 is provided with a box cover 2, the inside of the box body 1 is provided with an anti-scratch mechanism 3, and the interior of the anti-scratch mechanism 3 is fixed An extrusion plate 301 is installed, and the side of the extrusion plate 301 away from the center of the box body 1 is fixedly connected with an extrusion rod 302, and the side of the extrusion rod 302 is provided with a chute 303, and the side of the extrusion rod 302 is rotatably connected with a detection rod 305 The side of the detection rod 305 away from the center of the box body 1 is provided with an extrusion frame 306, and the side of the detection rod 305 away from the extrusion frame 306 is rotationally connected with a power storage rod 304, and the inside of the anti-wringing mechanism 3 is provided with a buffer mechanism 4, A screw 401 is fix...

Embodiment 3

[0030] Example 3: Please refer to Figure 1-5, a transport box for edible packaging film packaging products, comprising a box body 1, the top of the box body 1 is provided with a box cover 2, the inside of the box body 1 is provided with an anti-scratch mechanism 3, and the interior of the anti-scratch mechanism 3 is fixed An extrusion plate 301 is installed, and the side of the extrusion plate 301 away from the center of the box body 1 is fixedly connected with an extrusion rod 302, and the side of the extrusion rod 302 away from the extrusion plate 301 is fixedly connected with a metal block 307, and the metal block 307 is away from One side of the extruding plate 301 is provided with a conductive plate 308, and the inside of the box body 1 is provided with a holding plate 319, and the bottom of the holding plate 319 is rotatably connected with a support block 309, and the inside of the support block 309 is provided with an inflatable chamber 313 for inflating air. The chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com