Lifting assembly for building materials

A technology for building materials and components, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of difficult to control balance, difficult to bundle and fix pipes, and achieve the effects of avoiding unbalanced falling, improving construction efficiency and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

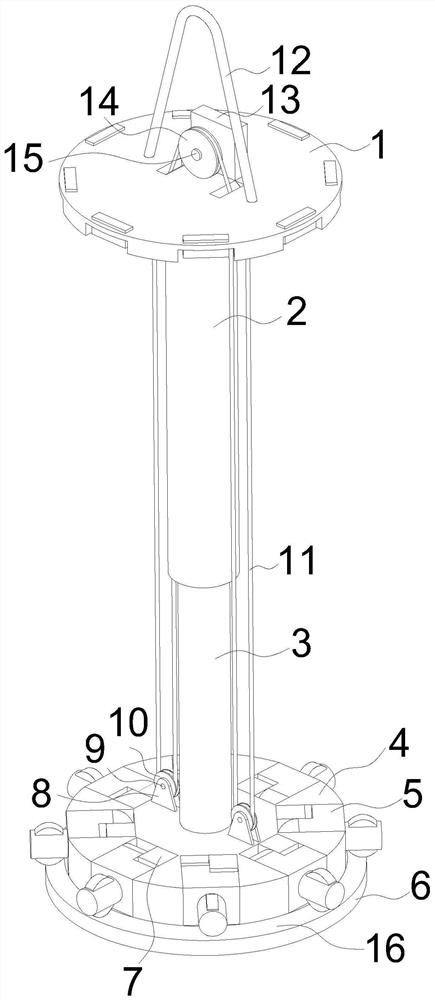

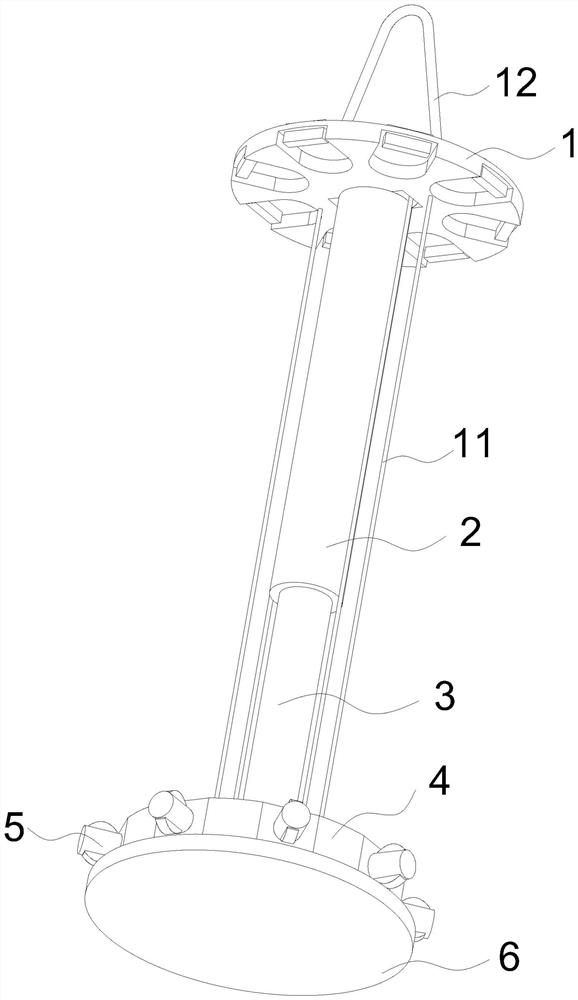

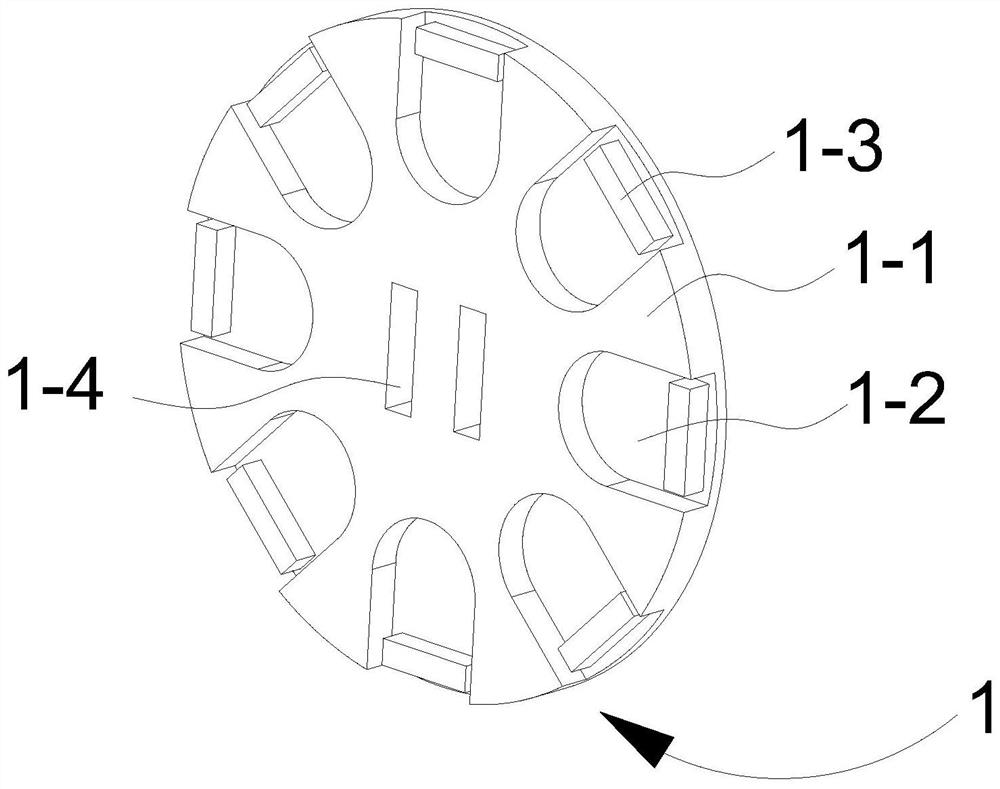

[0033] see Figure 1-6 The lifting assembly for building materials shown is a lifting assembly for building materials that can automatically bind and fix pipes and is easy to control the balance of pipes during the lifting process. Specifically, a lifting assembly for building materials includes a base plate 4 , a steering device 5 and a fixed motor 7 .

[0034] One end center of the base plate 4 is symmetrically provided with eight motor installation grooves 4-2, and the other end of the base plate 4 is symmetrically provided with shaft through holes 4-1 with respect to the motor installation grooves 4-2, and the motor installation groove 4-2 is fixedly provided with a fixed Motor 7, motor shaft 19 is controlled on the fixed motor 7, and steering gear 5 is fixedly arranged on motor shaft 19, and steering gear 5 comprises steering block 5-1, and offers motor shaft through hole 5-4 on the steering block 5-1, The motor shaft 19 is positioned at the motor shaft through hole 5-4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com