Unhooking device for guide rod pile hammer

A technology of piling hammer and decoupling device is applied in the field of decoupling device, which can solve the problems of heavy cylinder hammer and not particularly smooth decoupling action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

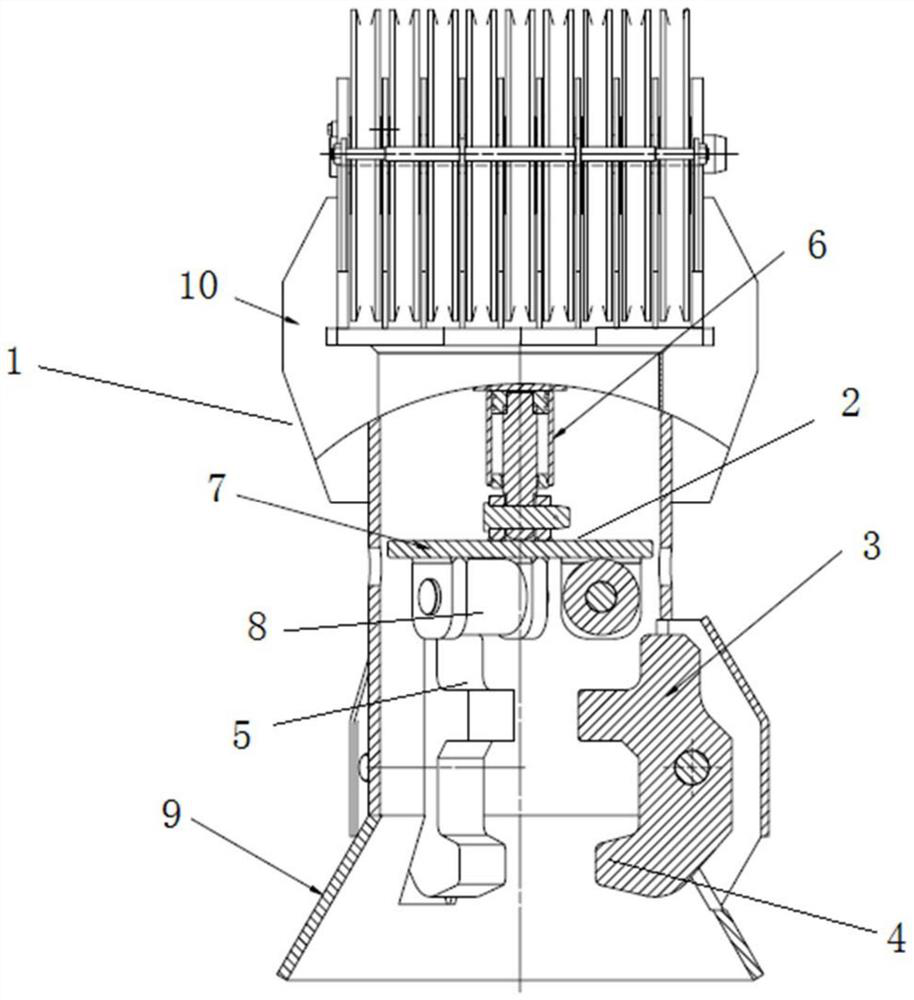

[0033] In order to realize the reliable and stable decoupling and hooking action of the piling hammer, this embodiment provides a decoupling device for the guide rod piling hammer, its structure see figure 1 As shown, it includes a decoupling frame 1, a decoupling actuator 2 that is installed on the decoupling frame 1 and can move up and down, and several groups of barb units located under the decoupling actuator 2. Each group of barb units is symmetrically arranged on the decoupling frame. Composed of two barbs 3, the barb 3 is rotatably arranged on the decoupling frame 1, the bottom of the barb 3 also extends laterally and forms a hook-shaped protrusion 4, and the upper part of the barb 3 is also provided with a side wall against the decoupling execution The opening slot 5 of the part 2; when the decoupling actuator 2 moves down to pin the opening slot 5, the barb 3 is locked and the two hook-shaped protrusions 4 are relatively close to and hooked on the piling hammer (that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com