Intake system for internal-combustion engine of hand-hold work tool

A technology of an air intake system and an internal combustion engine, applied in the field of air intake system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

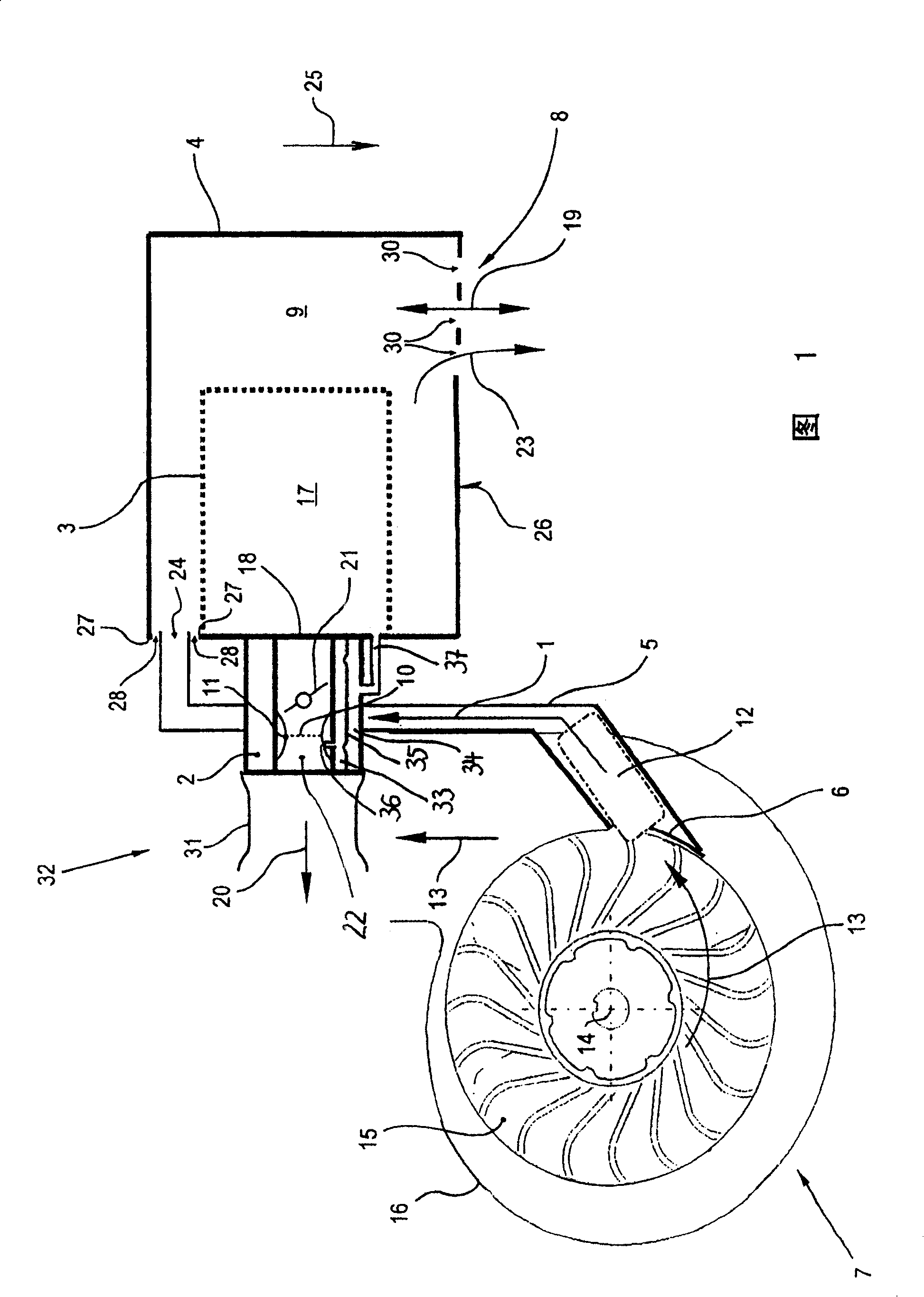

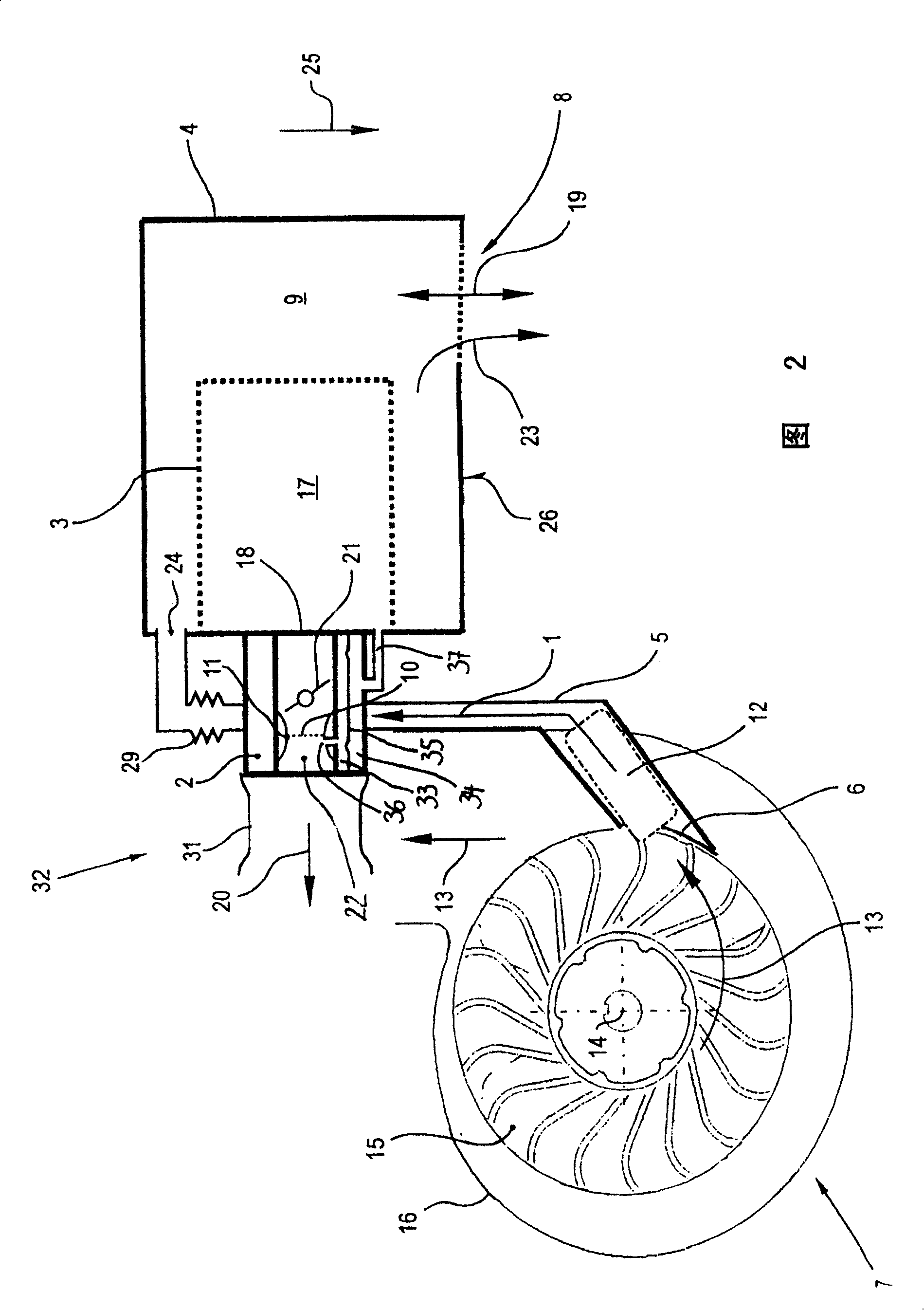

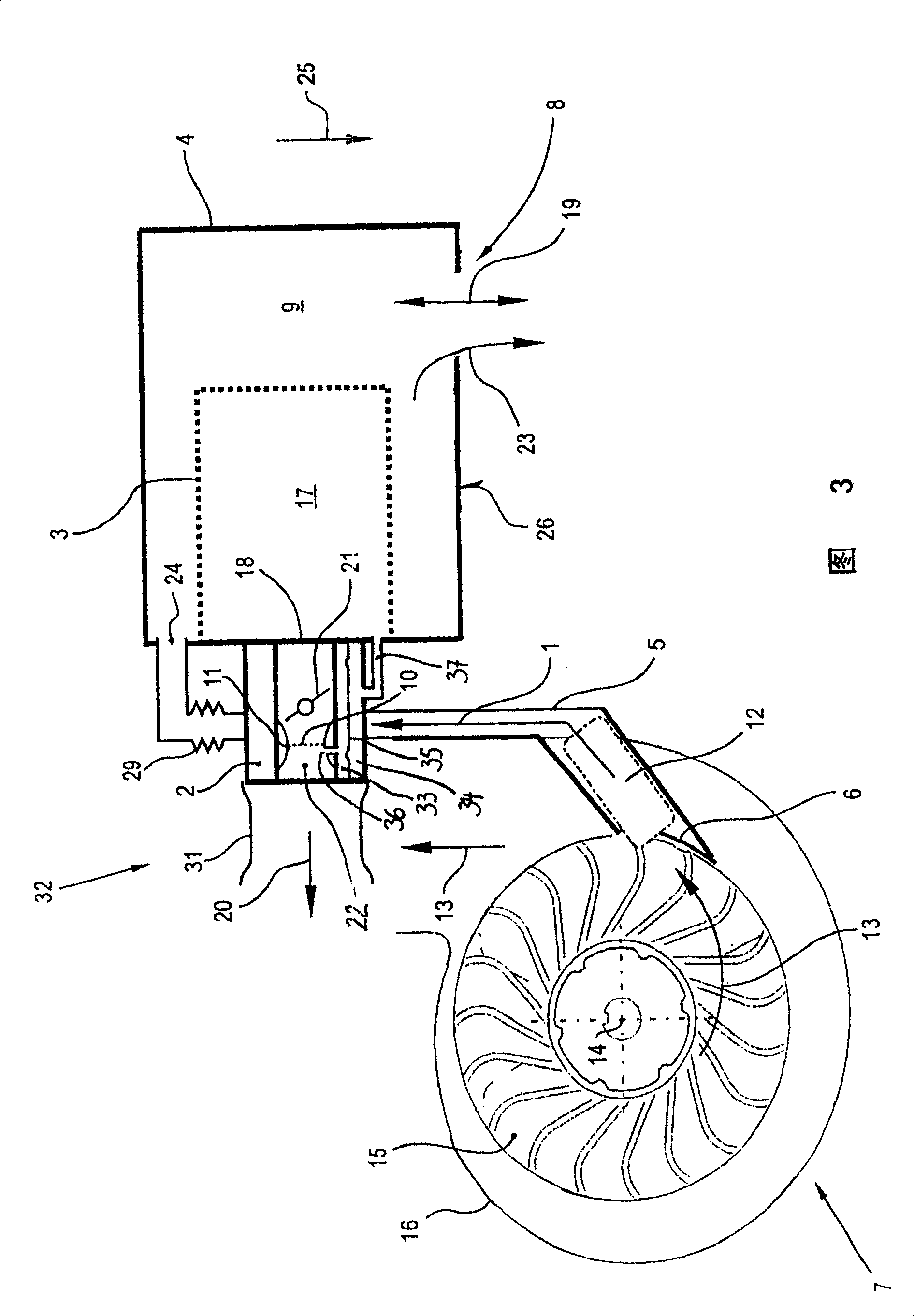

[0022] FIG. 1 schematically shows an exemplary embodiment of the air supply system according to the invention of a hand-held power tool not shown in detail, such as a chainsaw, cutter, suction / blowing tool, etc. FIG. The air intake system shown is used to prepare the combustion air indicated by the arrow 1 for a not shown internal combustion engine for driving a hand-held power tool, and includes a carburetor 2, an air filter upstream of the carburetor 2 Cleaner 3 and a filter box 4 that surrounds air cleaner 3 outside. A vibration gap 32 is formed between the carburetor 2 , which is rigidly mounted on the power tool, and the elastically mounted internal combustion engine, and an elastic coupling 31 is provided for bridging this gap to connect the carburetor 2 to the internal combustion engine.

[0023]The part of the intake system shown is a cooling air fan 7 for cooling the internal combustion engine, in which a combustion air channel 5 leads from an extraction opening 6 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com