Beam-column joint connection structure and hoisting technology of prefabricated concrete building

A technology for concrete buildings and beam-column joints, which is applied in building construction, construction, and building materials processing, etc., can solve problems such as unstable connection of beam-column joints, and achieve the effects of short construction period, stable connection, and increased use functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

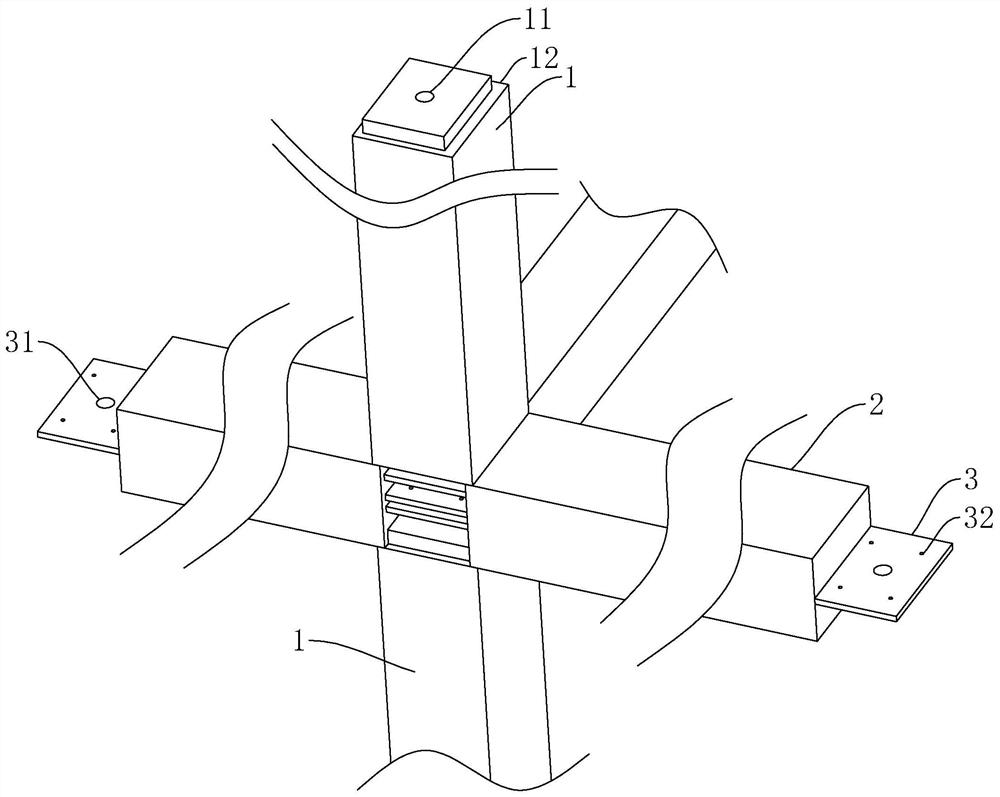

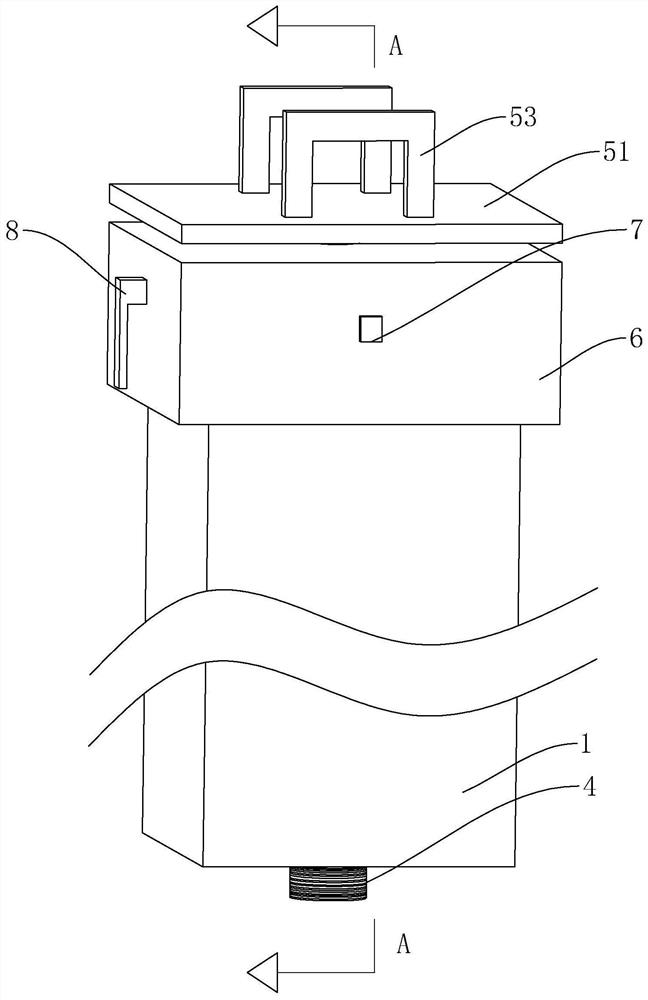

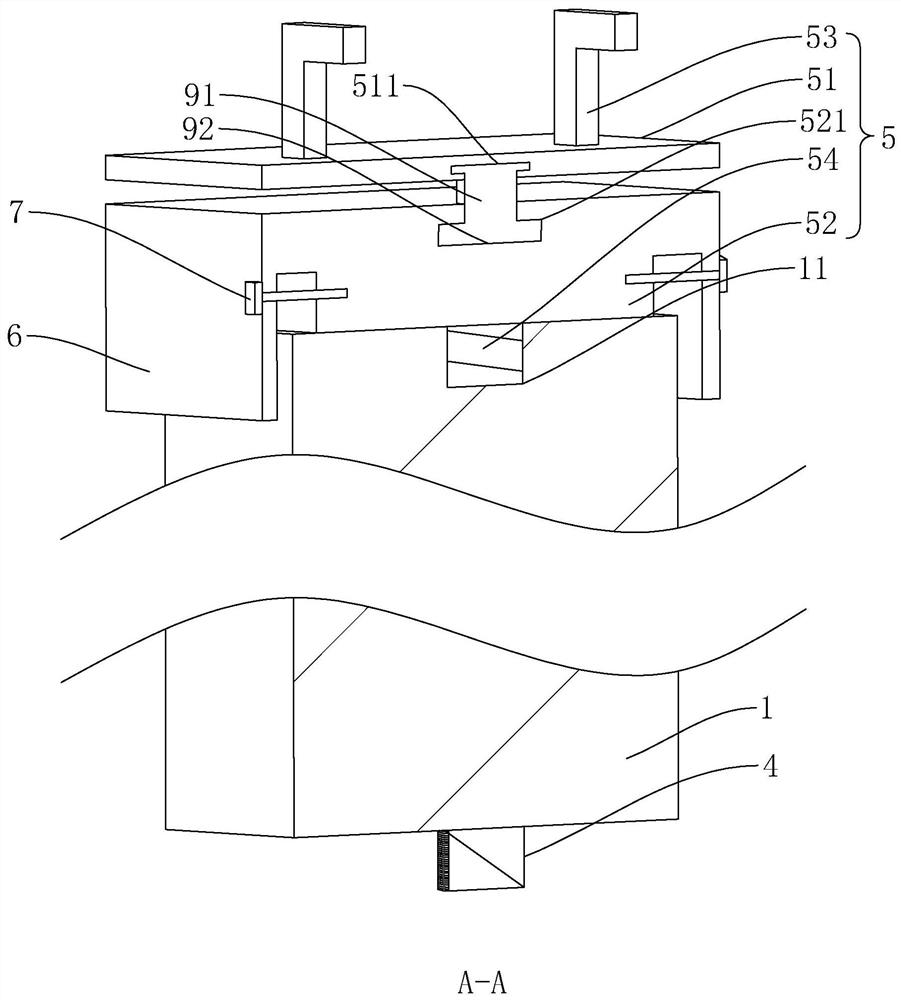

[0030] Attached to the following Figure 1-3 The present invention will be described in further detail.

[0031] A beam-column joint connection structure and hoisting process of a prefabricated concrete building disclosed in the embodiments of the present application, such as figure 1 , 2 As shown, when the beam 2 is prefabricated in the factory, the connecting plate 3 is pre-embedded in the beam 2, the connecting plate 3 protrudes from both ends of the beam 2, the upper middle of the column 1 is provided with a threaded groove 11, and the upper end face of the column 1 is provided with a circular groove 11. The number of the limiting grooves 12 and the beams 2 is determined according to the actual construction site conditions. In the present invention, the upper end of the column 1 is overlapped with three beams 2 .

[0032] The column 1 is in the shape of a cuboid, and a screw 4 is vertically connected to the middle of the lower end face of the column 1. The screw 4 is scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com