O-methoxyacetanilide nitration reaction thermal safety risk assessment method

A technology of o-methoxyacetanilide and nitration reaction, which is applied in the field of nitration technology and can solve problems such as vacancies

Pending Publication Date: 2021-10-15

GANSU RES INSTION OF CHEM IND GRICI

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Aiming at the deficiencies of the prior art, the present invention provides a thermal safety risk assessment method for the nitration reaction of o-methoxyacetanilide, which solves the problem that there is a vacancy in the current domestic nitration process reaction thermal safety risk assessment method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0036] An embodiment of the present invention provides a thermal safety risk assessment method for the nitration reaction of o-methoxyacetanilide, comprising the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Login to View More

Abstract

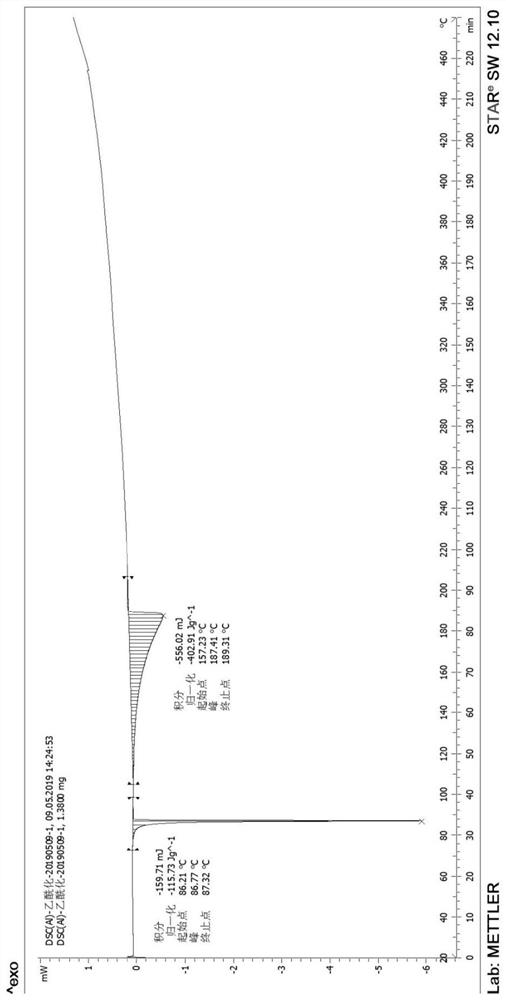

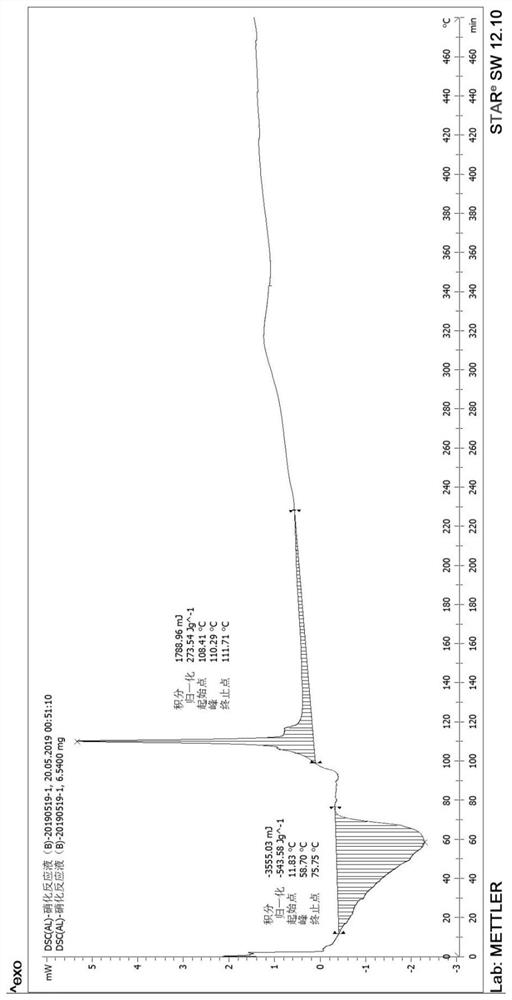

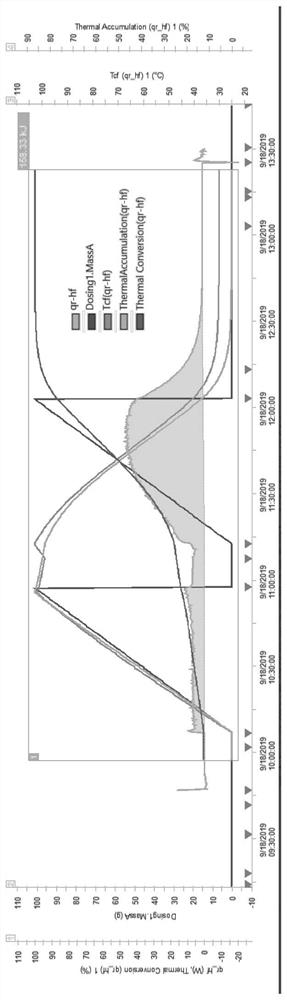

The invention provides an o-methoxyacetanilide nitration reaction thermal safety risk assessment method, and relates to the technical field of nitration processes. The o-methoxyacetanilide nitration reaction thermal safety risk assessment method comprises the following steps: step 1, testing the thermal stability of a material; step 2, reaction calorimetry test of nitration reaction; step 3, secondary decomposition test of nitration reaction completion liquid; and 4, carrying out nitration reaction safety risk assessment. A safety risk assessment model for nitration reaction heat of o-methoxyacetanilide is established through technical contents, and effective technical support and guarantee can be provided for production process heat safety and production safety accident prevention of a nitration process according to an assessment result. The method is of great significance to safety production and major accident prevention and control in the chemical industry.

Description

technical field [0001] The invention relates to the technical field of nitration technology, in particular to a thermal safety risk assessment method for nitration reaction of o-methoxyacetanilide. Background technique [0002] my country's chemical industry has already become a pillar industry of the national economy. There are a large number of chemical enterprises, the reaction types involve a wide range, and the production equipment and processes are complex and changeable. At the same time, most of the raw materials, intermediate products, products and wastes involved in the production process are flammable, explosive or toxic, harmful and corrosive. . These characteristics of chemical production determine that the possibility of production safety accidents is high, and the consequences of accidents are serious. In addition to causing a large number of direct losses such as casualties and property losses, they may also have a profound negative impact on the environment...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N25/48

CPCG01N25/484

Inventor 耿来红赵永生王涛冯维真许青梅

Owner GANSU RES INSTION OF CHEM IND GRICI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com