Traction device of flat knitting machine

A technology of a pulling device and a flat knitting machine, which is applied in knitting, weft knitting, textiles and papermaking, etc., and can solve problems such as good pulling effect, poor pulling effect, inability to realize fabric segmentation, layered pulling, etc. problems, to achieve a good pulling effect and avoid damage to the fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

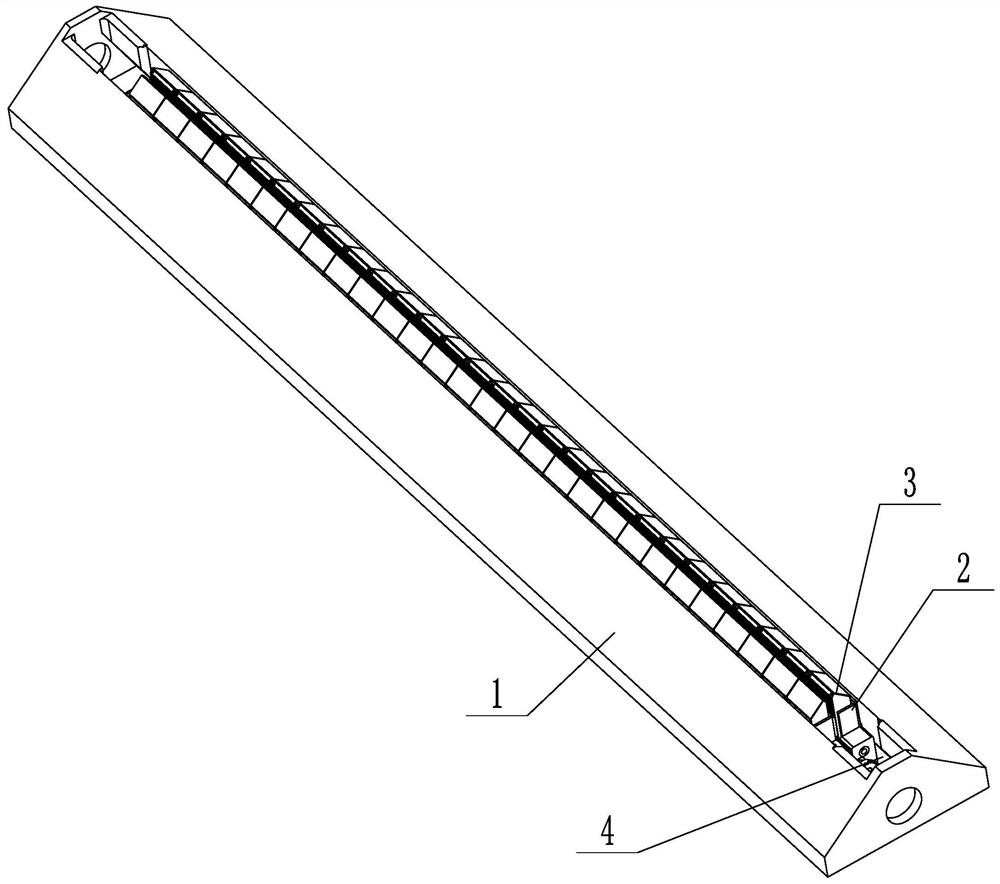

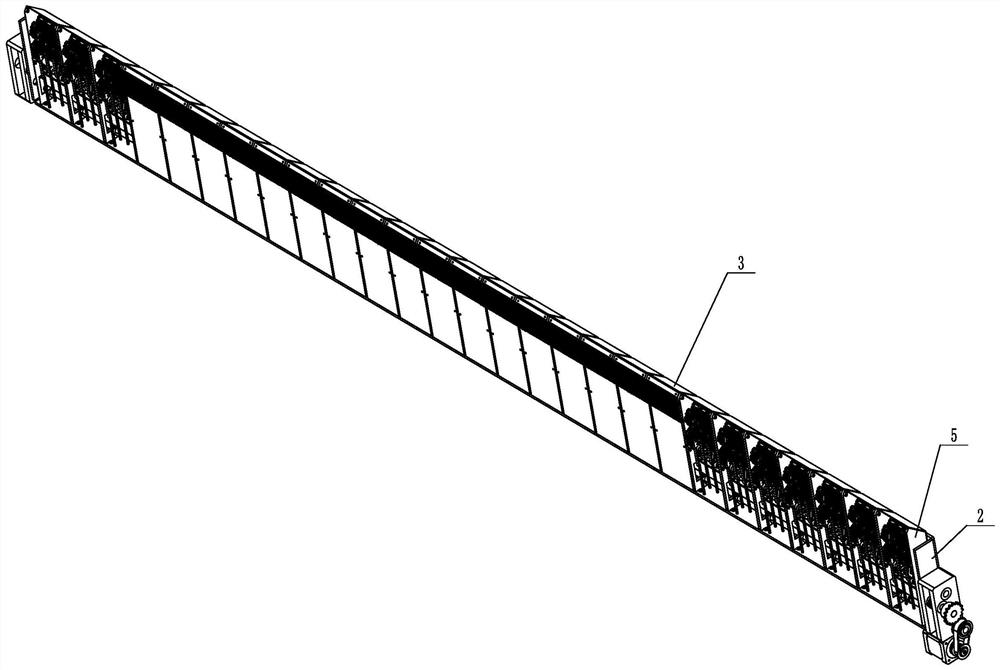

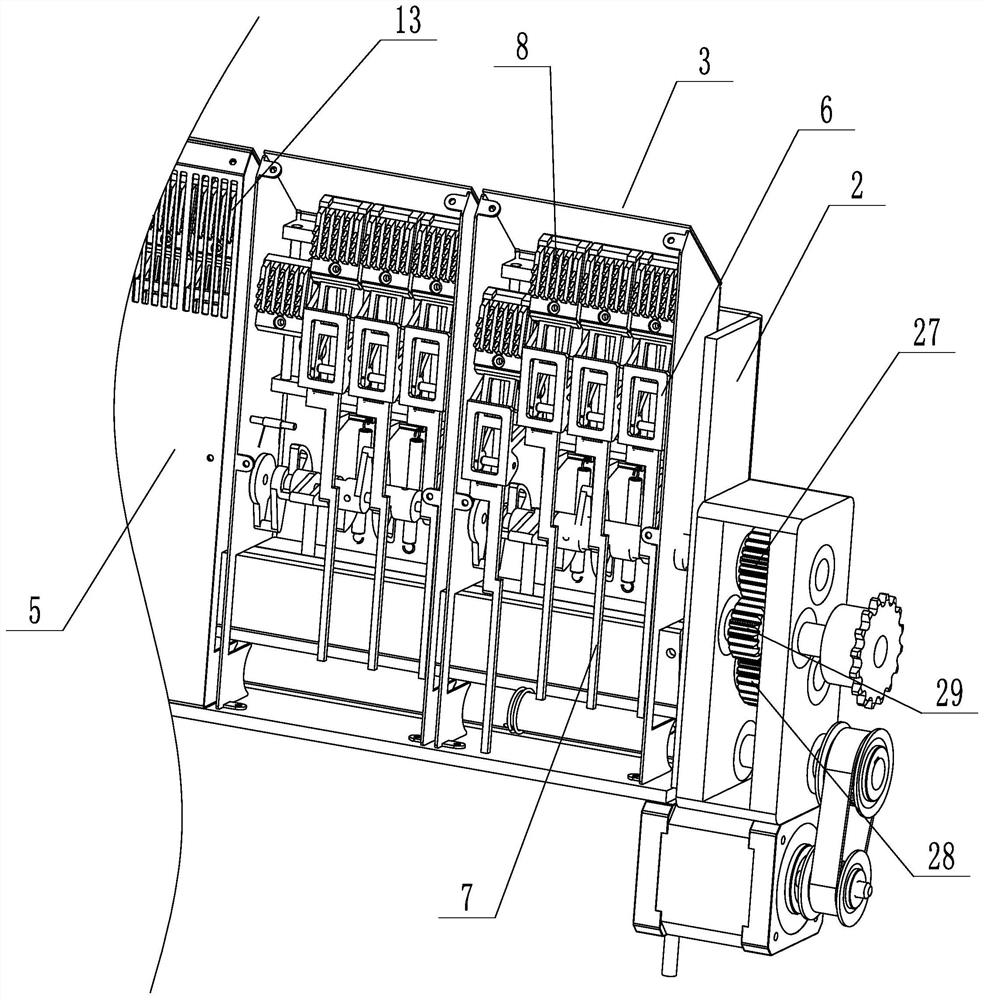

[0039] Embodiment 1: A kind of drawing device of flat knitting machine (see attached figure 1 To attach Figure 5 ), including a frame 1, a mounting frame 2, a drive assembly, and several pulling mechanisms 3 installed on the mounting frame at intervals. Two oppositely arranged mounting frames are installed, and a row of pulling mechanisms are installed on the mounting frames, the pulling mechanisms are arranged oppositely, and the fabric is pulled between the two oppositely arranged pulling mechanisms. The pulling mechanism includes an installation box 5 and several pulling units installed on the installation box. The pulling unit includes a lifting seat 6 that can be lifted and installed in the installation box, and an opening and closing rod 7 hinged on the lifting seat. The pulling rake 8 is installed, and the pulling rake can stretch out the installation box, and the lifting drive block 9 for driving the lifting seat to move and the deflection dial 10 for driving the ope...

Embodiment 2

[0047] Embodiment 2: A kind of drawing device of flat knitting machine (see attached Figure 6 ), its structure and principle can be similar to any one of Embodiments 1, 3, 4, 5, and 7 of the present application. The main difference is that the drive assembly in this embodiment includes a drive shaft and several drive shafts. On the transmission shaft, a drive shaft is installed in the installation box, and the lifting drive block and the deflection dial block are all arranged on the drive shaft; the lifting seat is provided with a rack 30, and the lifting drive block is provided with a section of arc-shaped meshing teeth 31, The meshing gear fits with the rack, the drive shaft rotates to drive the gear rack to move upward, the drive shaft rotates to make the deflection shift block touch the opening and closing rod, and the pulling rake at the upper end of the opening and closing rod retracts from the outside of the installation box to the inside .

Embodiment 3

[0048] Embodiment 3: A kind of pulling device of flat knitting machine (see attached Figure 7 ), its structure and principle can be similar to any other embodiment of the present application, the main difference is that in this embodiment, a rest motor 37 for driving the rest part to rotate is installed on the mounting bracket and the rest part one by one, and the rest part rotates It is installed in the installation box, and the rest part rotates eccentrically. One end of the rest part is provided with a worm gear 38, and the output shaft of the rest motor is connected with a worm screw 39, and the worm screw is connected with the worm gear drive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com