Process for processing leaves into tea

A leaf and process technology, which is applied in the field of leaf processing into tea technology, can solve the problems of affecting the quality and efficiency of rolling, excessive rolling of external tea leaves, and insufficient rolling force, so as to improve rolling efficiency and finished product quality, improve rolling quality, and reduce rolling. The effect of the difference in quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

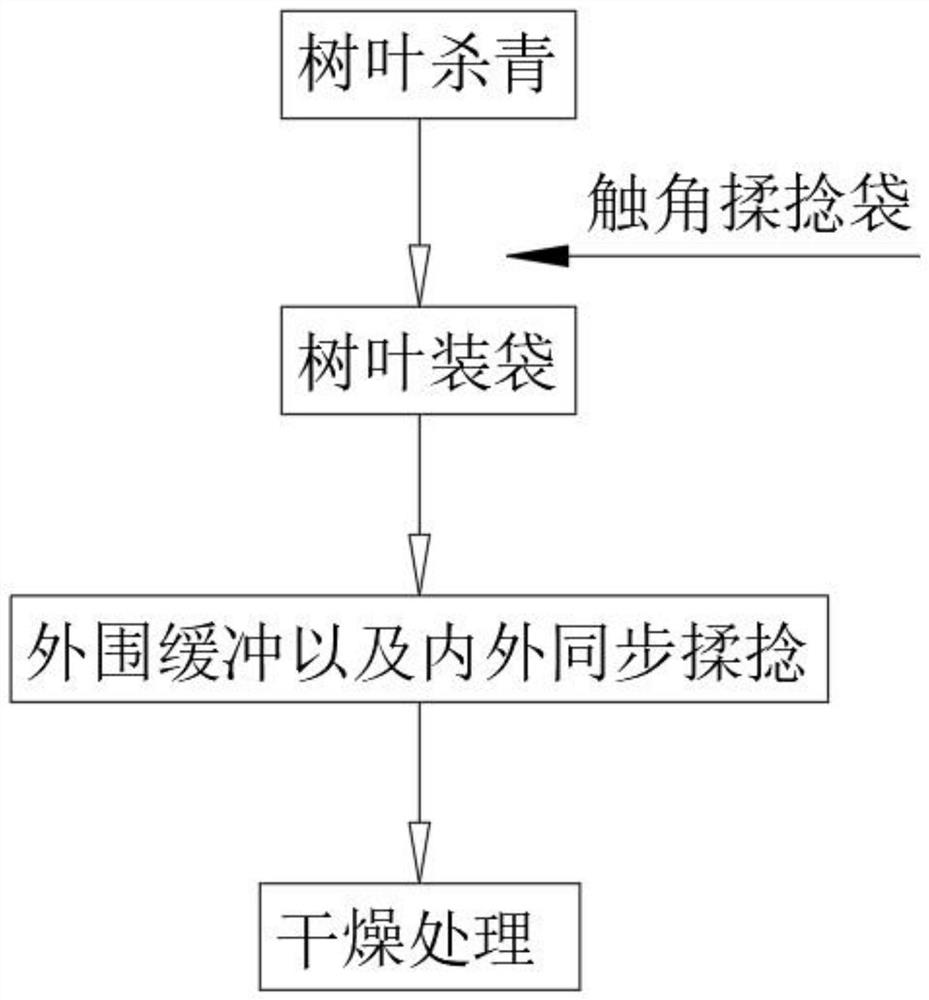

[0045] see figure 1 , a process for processing leaves into tea, comprising the following steps:

[0046] S1. Put the picked and cooled leaves into a hot pot, and stir-fry to kill them. The pot temperature is 150°C-200°C, and the stir-fry time is 15-30 minutes;

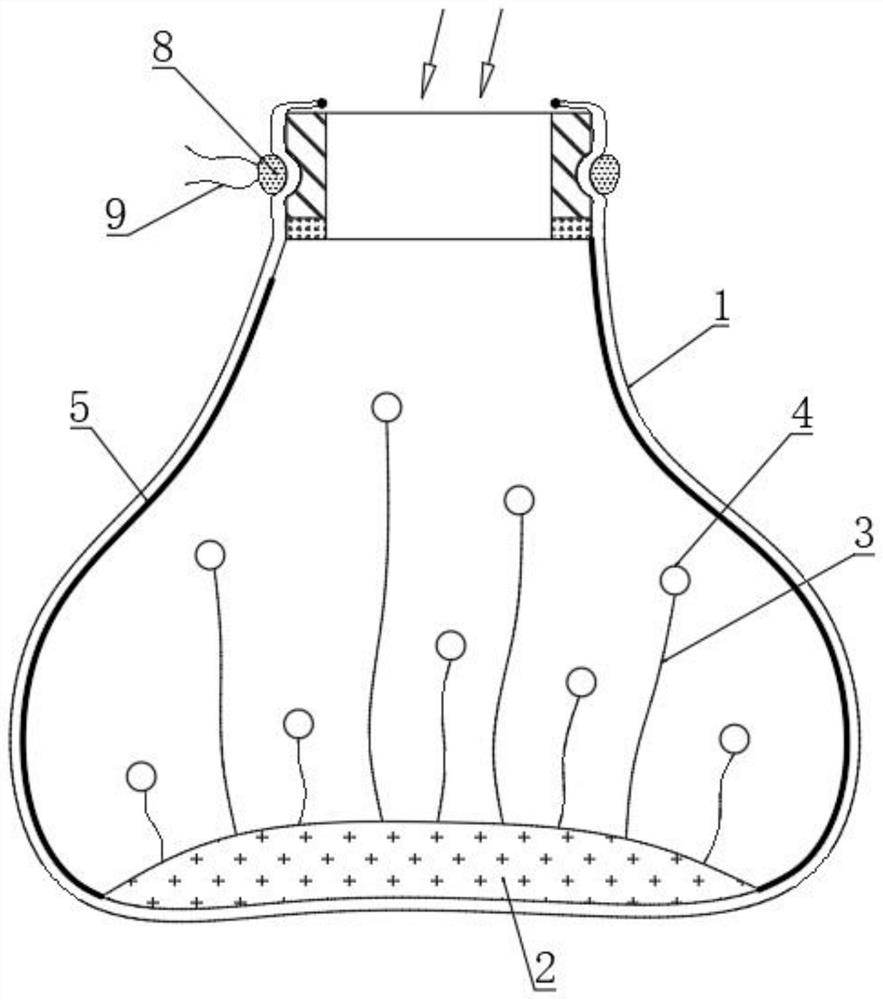

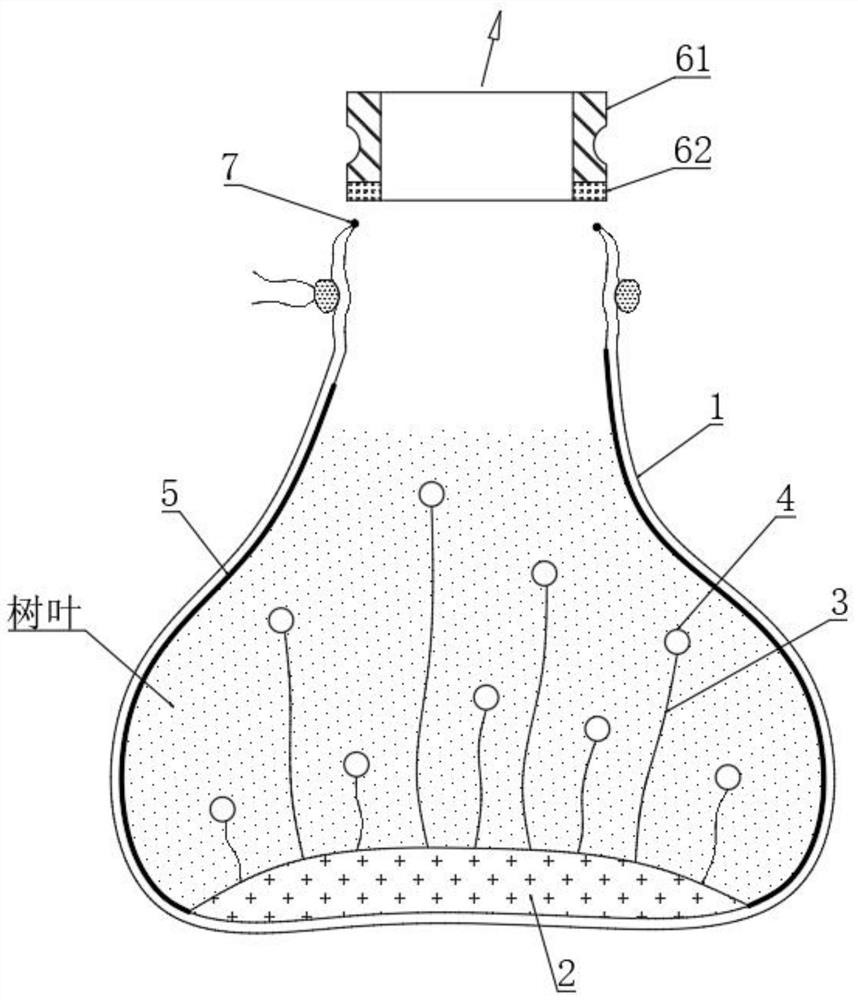

[0047] S2, adding the leaves after finishing in batches into the tentacles and kneading bags, and closing the tentacles and kneading bags;

[0048] S3. Follow the principle of "light first, then heavy, then light, gradual pressure, alternating light and heavy", and knead the antennae kneading bag wrapped with leaves;

[0049] S4. During the kneading process, adjust the position of the tentacles kneading bag, and apply force to multiple parts of the outer surface of the tentacles kneading bag in turn to realize the uniform force on the leaves. Synchronous kneading process;

[0050] S5, after kneading, open the tentacles and knead the bag, and pour out the leaves;

[0051] S6. The leaves are dried in the sun or baked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com