Quick-preheating air sterilization equipment

An air sterilization and equipment technology, applied in the directions of deodorization, separation method, dispersed particle separation, etc., can solve the problems of slow heating, sterilization treatment, inability to achieve uniform heating in the early stage of the sterilizer, etc., to improve work efficiency, extend the The effect of entering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

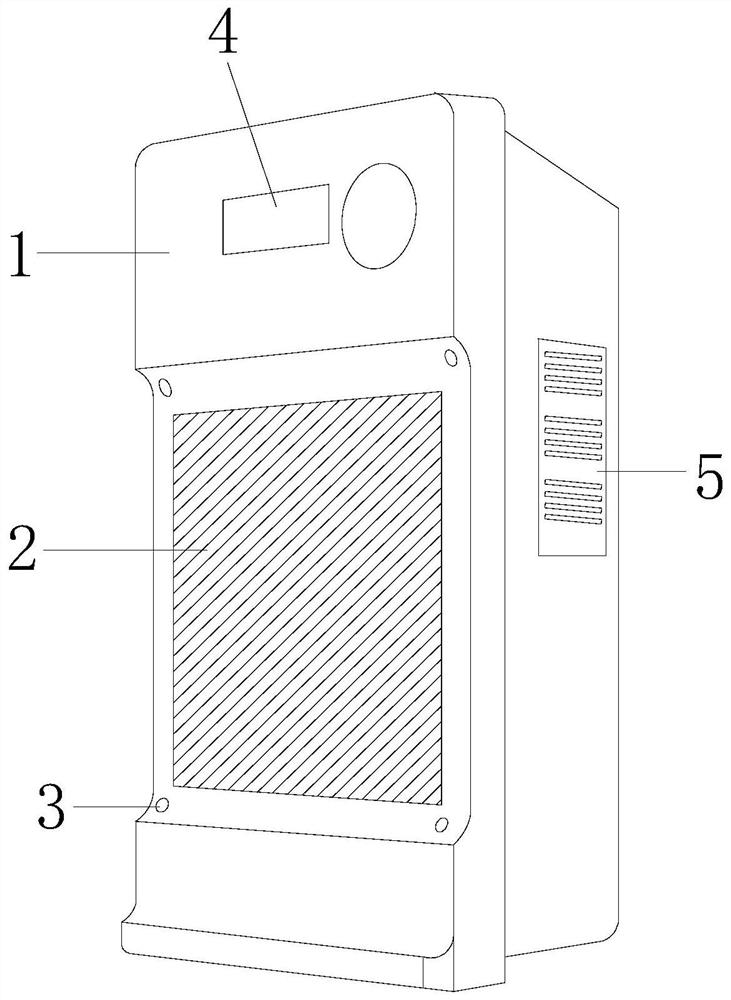

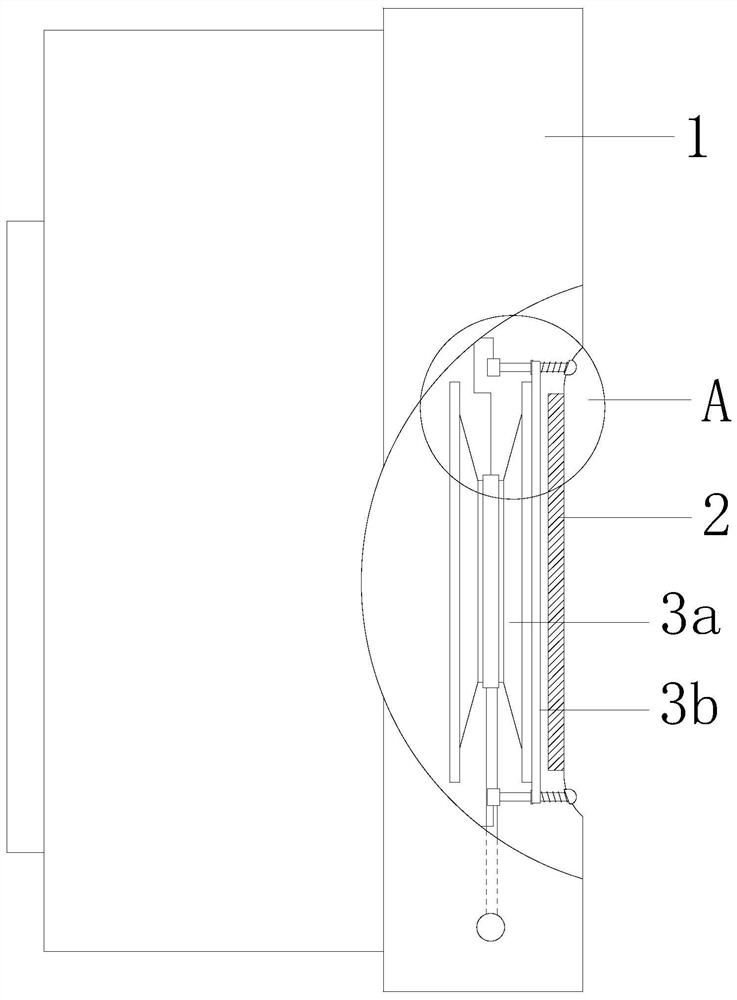

[0029] Such as Figure 1-Figure 4 As shown, the present invention provides a technical scheme of air sterilization equipment with fast preheating:

[0030] Such as Figure 1-Figure 2 As shown, a kind of air sterilization equipment with fast preheating, its structure includes equipment main body 1, air inlet plate 2, strengthening device 3, control panel 4, heat dissipation port 5, said air inlet plate 2 is installed in front of equipment main body 1 In the middle part of the surface, the strengthening device 3 is arranged inside the equipment main body 1 and is located on the rear surface of the air intake plate 2. The control panel 4 is installed on the upper part of the front surface of the equipment main body 1 and is electrically connected to the strengthening device 3. The heat dissipation port 5 is located on the right side of the equipment main body 1 and is an integrated structure. The strengthening device 3 includes a barrier structure 3a and a preheating mechanism 3...

no. 2 example

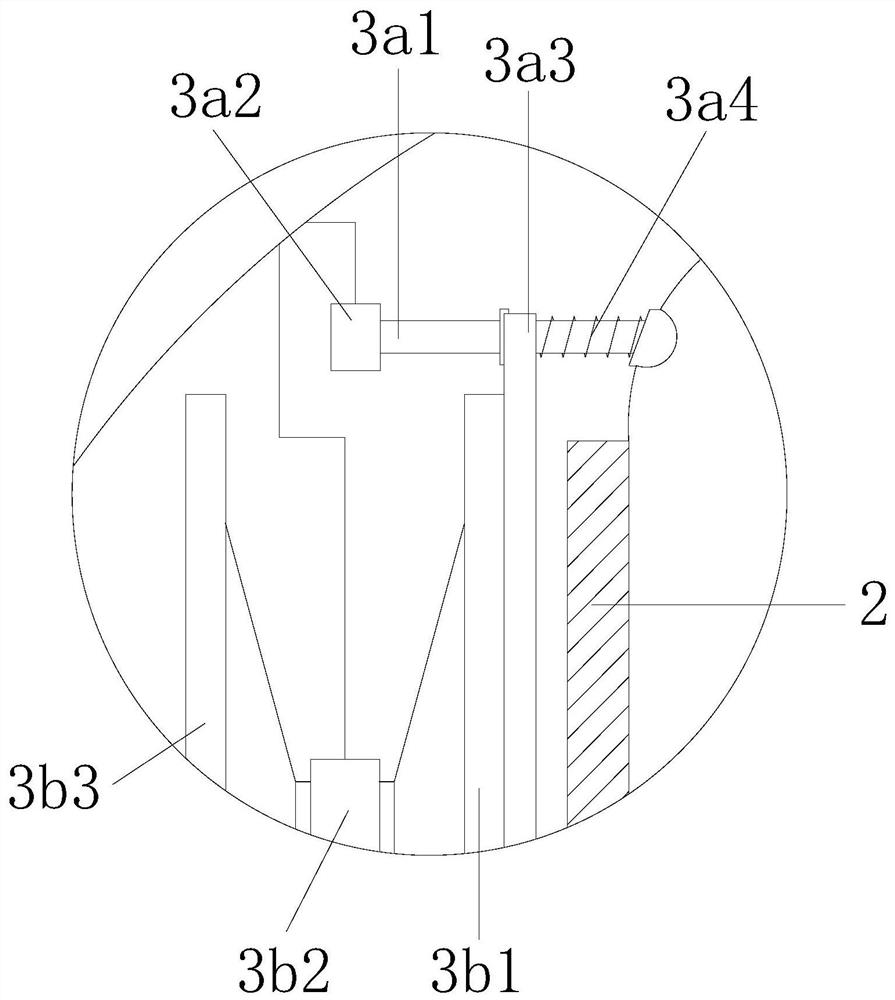

[0039] Such as image 3 , Figure 5 , Figure 6 As shown, the present invention provides a technical scheme of air sterilization equipment with fast preheating:

[0040] Such as image 3 , Figure 5 As shown, a kind of air sterilization equipment with fast preheating, its structure includes the preheating mechanism 3b including a mounting plate 3b1, an auxiliary heating element 3b2, and an exhaust plate 3b3, and the mounting plate 3b1 is arranged behind the movable frame plate 3a31 The auxiliary heating element 3b2 is arranged on the rear surface of the mounting plate 3b1 and welded together, the auxiliary heating element 3b2 is electrically connected to the control panel 4, and the exhaust plate 3b3 is arranged on the rear surface of the auxiliary heating element 3b2 and Through the connection, it is beneficial to realize the preheating treatment of the air entering for the first time, so as to improve the sterilization work of the air sterilization equipment.

[0041] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com