Tin slag filtering device for tin plating on surface of novel packaging material

A new type of packaging and filtration device technology, applied in filtration and separation, membrane filters, fixed filter element filters, etc., can solve the problems of low degree of automation, high production cost, low metal solution filtration efficiency, etc. The effect of speeding up the filtration and avoiding the premature scrapping of the filter plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

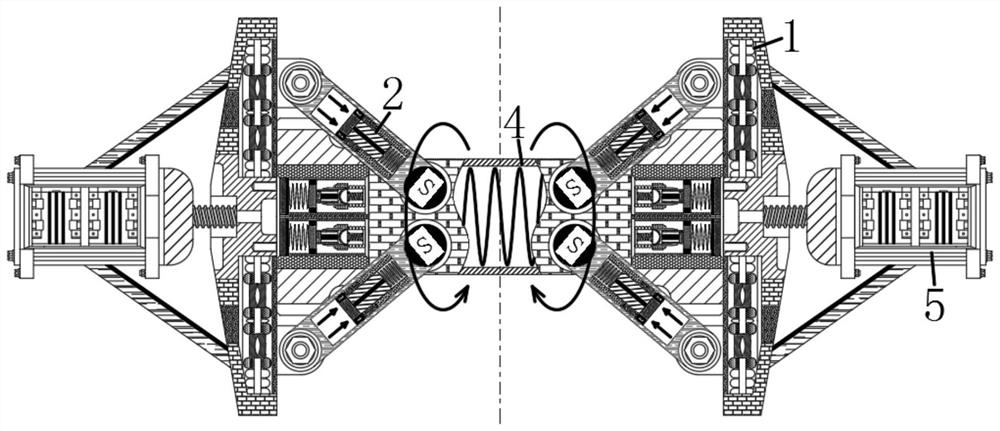

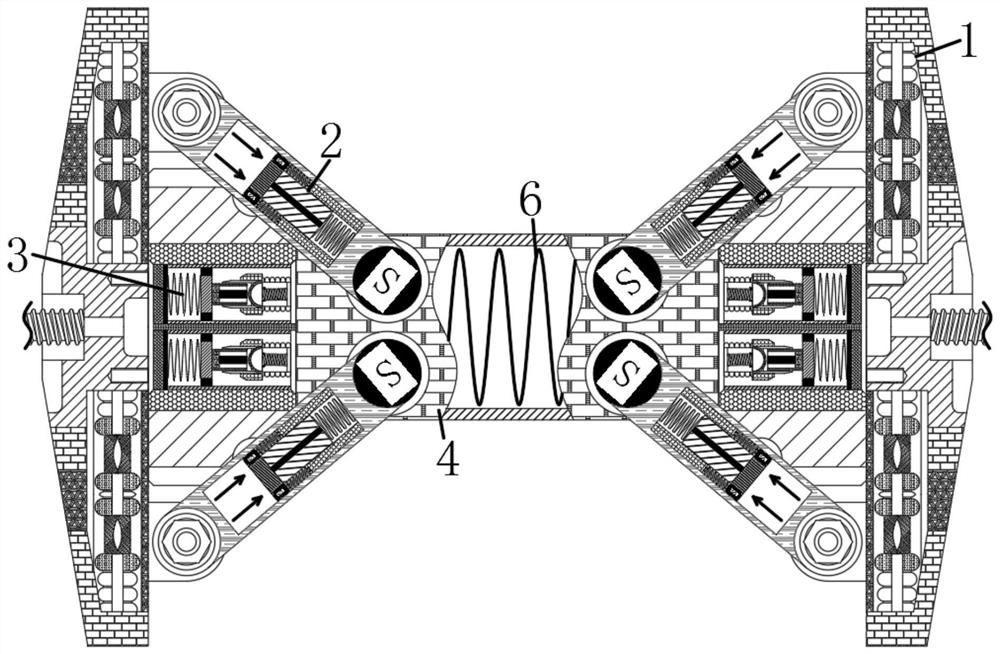

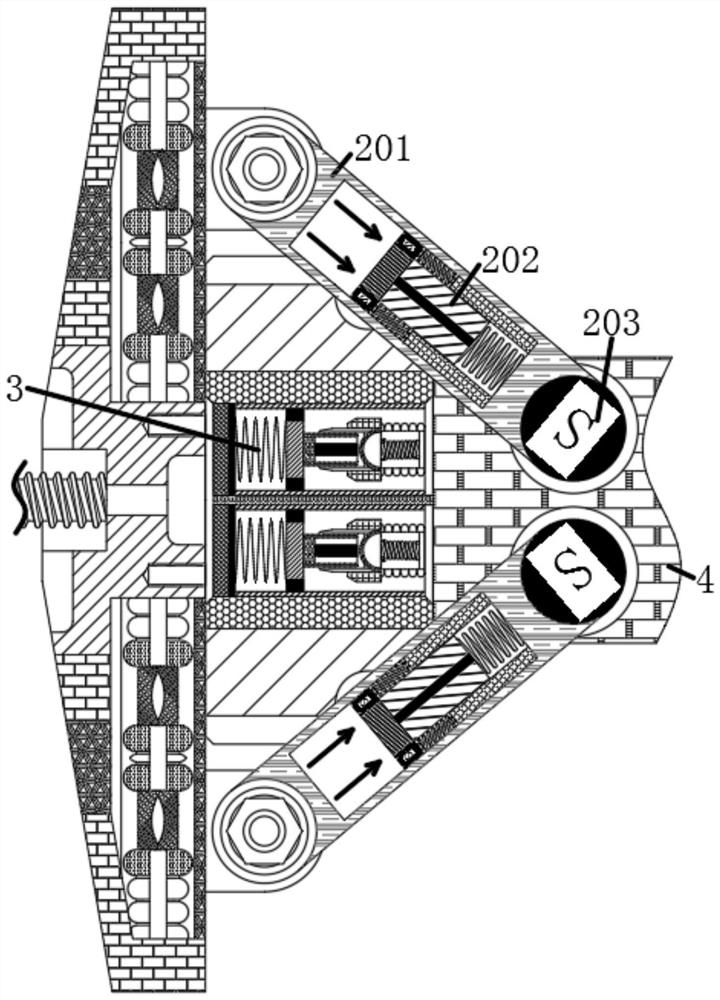

[0027] See Figure 1-4 A tin residue filter device for the surface of the new package material, including the frame 1, the inner wall welded by the frame 1, preventing the filter plate 4 exjane from the solder residue, and the outer wall of the filter plate 4 is rotated and connected to the sheet 2 mechanism 2 The sheeting mechanism 2 includes a finite sleeve 201, and the inner wall of the limit sleeve 201 is opened with a collector bin 206, and the inner wall of the collector bin 206 is slidably connected to the piston plate 204, and the piston plate 204 is disposed between the piston plate 206. There is a sealed rubber strip, the outer wall of the collector bin 206 is coupled to the molten tank with the molten tank seal cartridge, and the drive rod 202 is welded, and the transmission rod 202 is welded from one end of the piston plate 204 with a reset spring 205. The restricted sleeve 201 is rotated from one end of the collector bin 206 to be connected to the fixed magnetic block ...

Embodiment 2

[0029] See Figure 1-5 A tin residue filter device for the surface of the new package material, including the frame 1, the inner wall welded by the frame 1, preventing the filter plate 4 exjane from the solder residue, and the outer wall of the filter plate 4 is rotated and connected to the sheet 2 mechanism 2 The opposite ends of the sheet mechanism 2 are provided with a vortex heating tube 6 that prevents the solidification of tin slag, welding the adjustment mechanism 3, including the adjustment mechanism 3, and the adjustment mechanism 3 includes a thermal change spring 301, and the thermal change spring 301 is large. The cadmium alloy is made, and the deformation pressure of the thermal change spring 301 is larger than the deformation pressure of the compression spring 304, and the outer wall of the thermal change spring 301 welded the drive rod 302, the drive rod 302 is welded from one end of the thermal change spring 301, and the contact 33, touch The outer wall of the block...

Embodiment 3

[0031] See Figure 1-5 A tin slag filter device for the surface of the new package material, including the rack 1, the frame 1 is in the sealed bin of the molten tin, rotates the left and right wall of the rack 1 and the left and right wall of the molten tin. The inner wall of the rack 1 is opened with a slide that engages the drive screw, and the inner wall of the frame 1 is welded to prevent the filter plate 4 exjane from the solder slag. The outer wall of the filter plate 4 is rotated and connected to the sheet. 2, the lower body 2 mechanism 2 Including a finite sleeve 201, the inner wall of the limit sleeve 201 is opened with a collector bin 206, and the inner wall of the collector bin 206 is slidably connected to the piston plate 204, and the piston plate 204 is provided with a sealing rubber strip between the piston plate 206. The outer wall of the collector bin 206 is coupled to the molten tubular sealing cartridge, and the outer wall of the piston plate 204 is welded, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap