Full-automatic cleaning equipment applied to urban sewage treatment

A technology for cleaning equipment and urban sewage, which is applied in the field of urban sewage treatment and resource utilization, and can solve the problems of sewage cleaning, recycling, filtration flow reduction, sewage flow pressure increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] as attached figure 1 to attach Image 6 Shown:

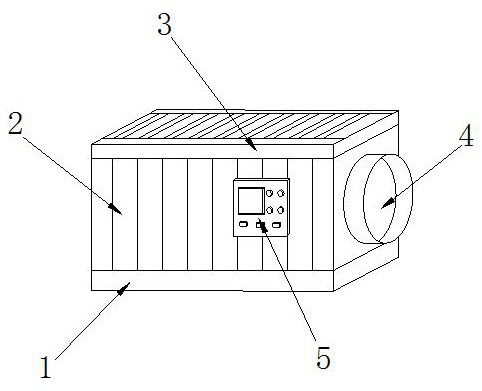

[0031] The present invention provides a fully automatic cleaning device for urban sewage treatment, its structure includes a base 1, a working box 2, a top plate 3, a delivery pipe 4, and a control panel 5, and the upper end of the base 1 is connected to the lower end of the working box 2 by studs The upper end of the work box 2 is bolted to the lower end of the top plate 3, the left end of the delivery pipe 4 is welded to the right end of the work box 2, and the rear end of the control board 5 is embedded and connected to the front end of the work box 2.

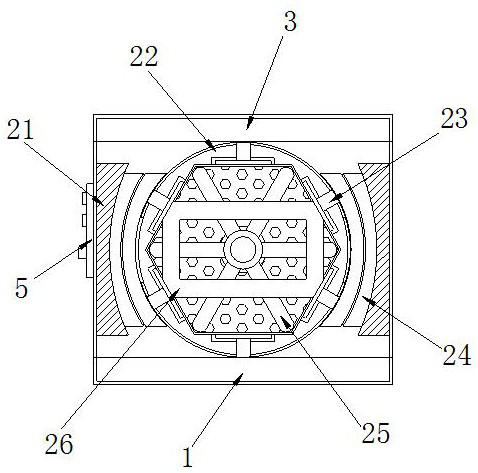

[0032] Wherein, the working box 2 is provided with a supporting plate 21, a fixed ring 22, a supporting frame 23, a pressing plate 24, a scraping device 25, and a retaining frame 26, and the inner side of the supporting plate 21 is engaged with the outer side of the pressing plate 24. The inner side of the fixed ring 22 is riveted with the outer side of the support f...

Embodiment 2

[0040] as attached Figure 7 to attach Figure 9 Shown:

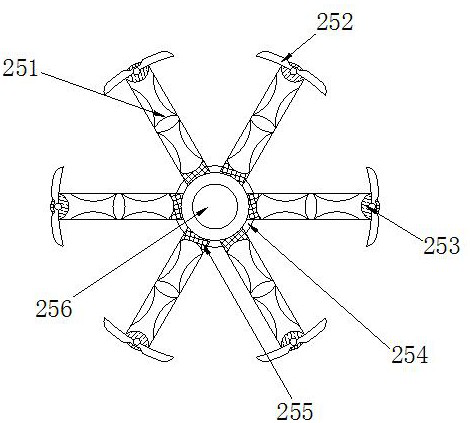

[0041] The present invention provides a fully automatic cleaning device for urban sewage treatment. The baffle 261, a rotating column 262, a fixed plate 263, a connecting bar 264, a connecting frame 265, and a guide port 266 are arranged inside the baffle frame 26. The outer side of the baffle plate 261 is connected with the inner side of the connecting frame 265, the inner side of the rotating column 262 is riveted with the outer side of the connecting frame 265, the inner side of the fixing plate 263 is fixed with the outer side of the connecting bar 264, and the front end of the connecting bar 264 is connected with the baffle plate. The front ends of 261 are attached to each other, and the guide opening 266 is set on the inner side of the fixing plate 263 for guiding fit. The fixing plate 263 is in a convex shape, so that the rotating column 262 can be fixed on the inner side of the fixing block 263 .

[0042] Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com