Microfiltration device with sedimentation bin for submerged cultivation

A silo-type, micro-filtration technology, applied in the direction of filtration separation, filtration loop, separation method, etc., can solve the problems of poor positioning, difficult installation, and inconvenient replacement of filter screens, so as to reduce production costs and facilitate compaction. , the effect of saving breeding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

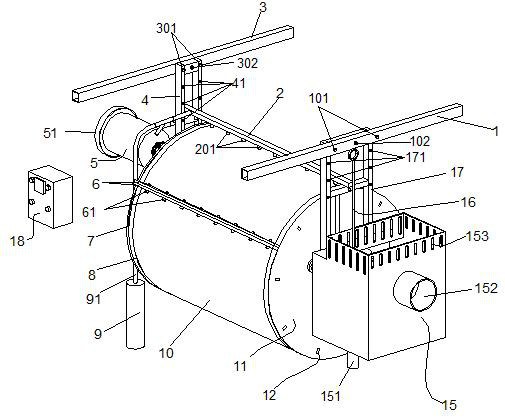

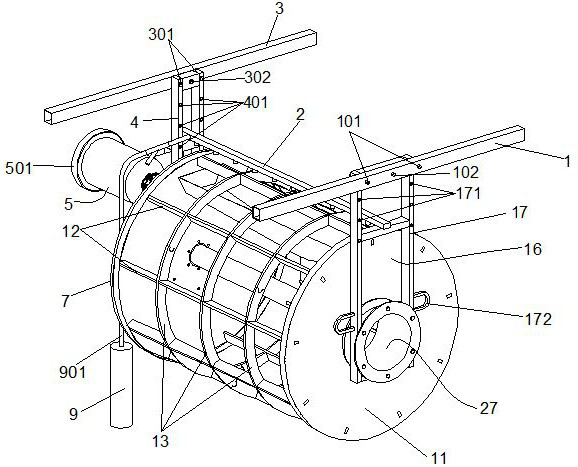

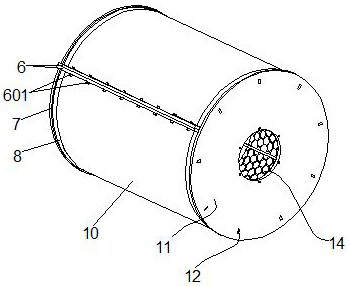

[0027] Now for further detailed description in conjunction with the accompanying drawings, it should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the The terms "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

[0028] like Figure 1-11 As shown, the described backwashing device comprises a central pipe, a booster pump 9, a backwashing pipe 2, a sewage pan 28 and a transmission mechanism, and the left and right of the described central pipe are respectively provided with concentric blowdown pipes 25 and intake pipes. The water pipe 27, the two pipes are separated by a certain distance as the water outlet, and are connected as a whole by a connecting bar 26. A dirt collection tray 28 and a backwash pipe 2 are installed directly above the central pipe, and a transmission mechanism is installed on the left side of the central pipe. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com