Ladder-type sleepers and railway tracks

A sleeper and ladder-type technology, which is applied in the field of sleepers, can solve the problems of exacerbated train vibration, deterioration of running stability and riding comfort, and achieve the effects of reducing workload, overcoming labor shortage, and enhancing bending rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

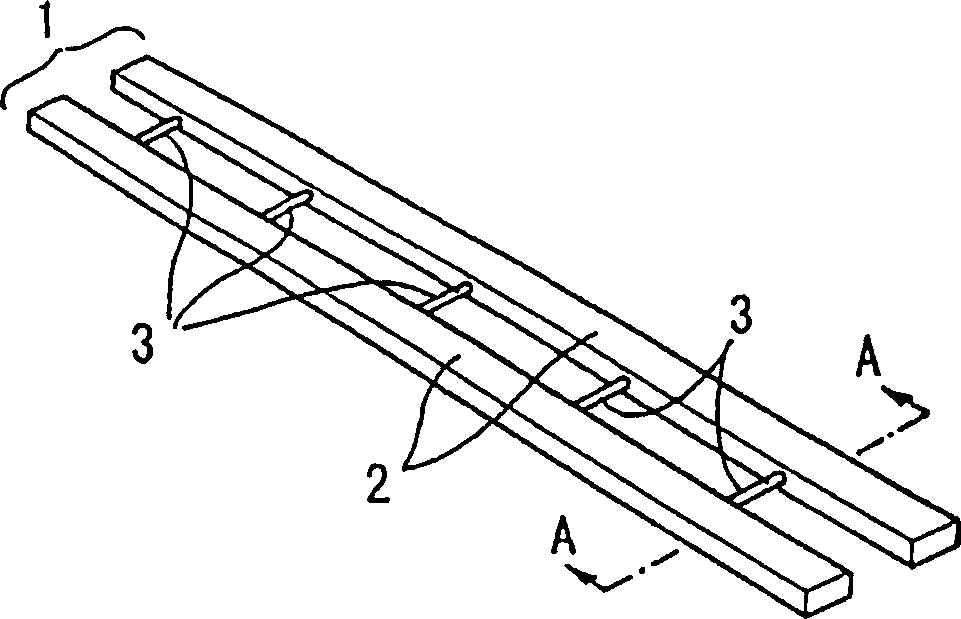

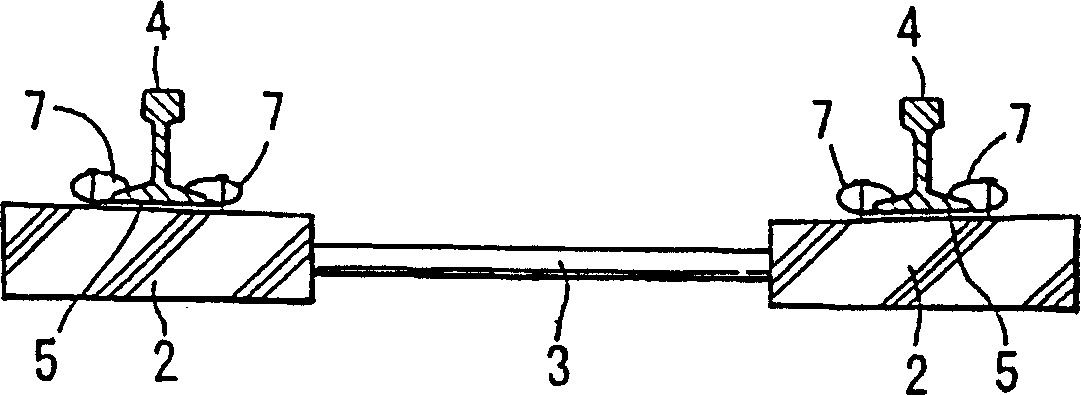

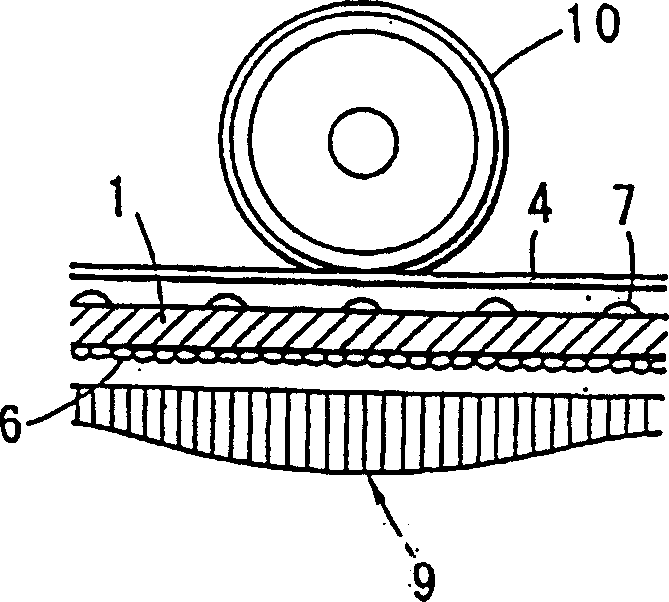

[0049] figure 1 It is a configuration diagram showing Embodiment 1 of the present invention. figure 2 is along figure 1 A cross-sectional view taken along line A-A in . Figure 3A with 3BIt is a diagram showing the distribution state of the ballast pressure of the ladder-type sleeper track structure of Example 1 and the distribution state of the ballast pressure of the conventional transverse sleeper-type track structure, respectively. In the figure, 1 is a ladder-type sleeper, 2 is a longitudinal beam, 3 is a connector connecting the longitudinal beam 2, 4 is a rail, and 5 is a rail pad placed between the rail 4 and the longitudinal beam 2 to absorb vibration (such as elastic material made of calibration film), 6 is the ballast buried in the ladder sleeper, 7 is the rail fastening device for connecting the rail 4 to the longitudinal beam 2, 8 is a conventional transverse sleeper, 10 is a wheel.

[0050] The ladder-type sleeper 1 of this embodiment comprises a pair of lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com