Environment-friendly water-soluble metal processing cutting fluid

A metal processing, water-soluble technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., to achieve the effect of reducing cost, excellent anti-electrolyte stability, and improving antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

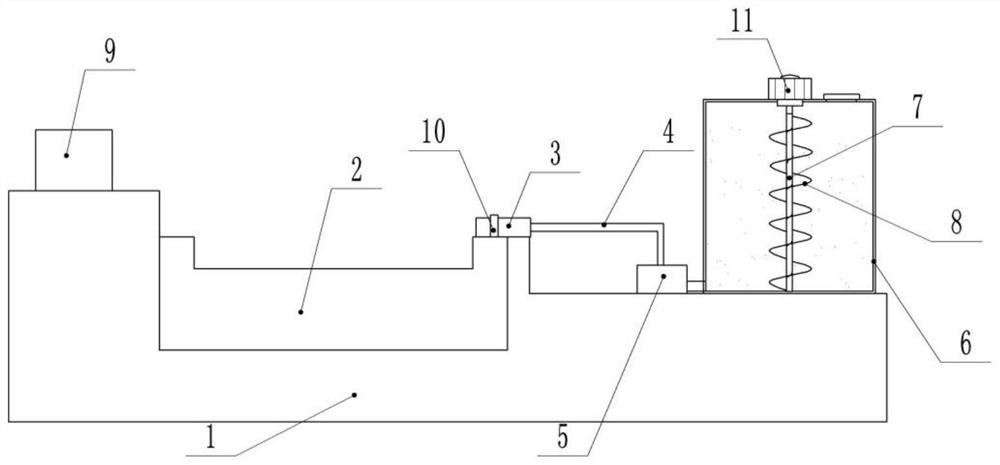

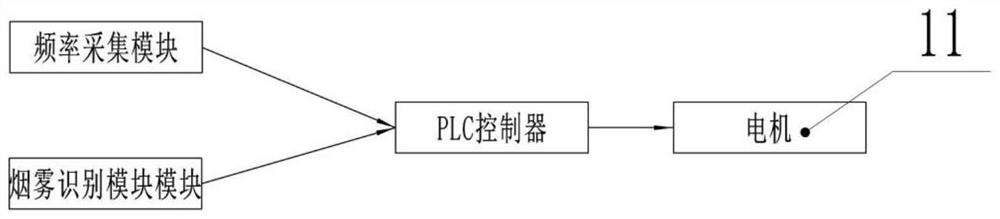

Image

Examples

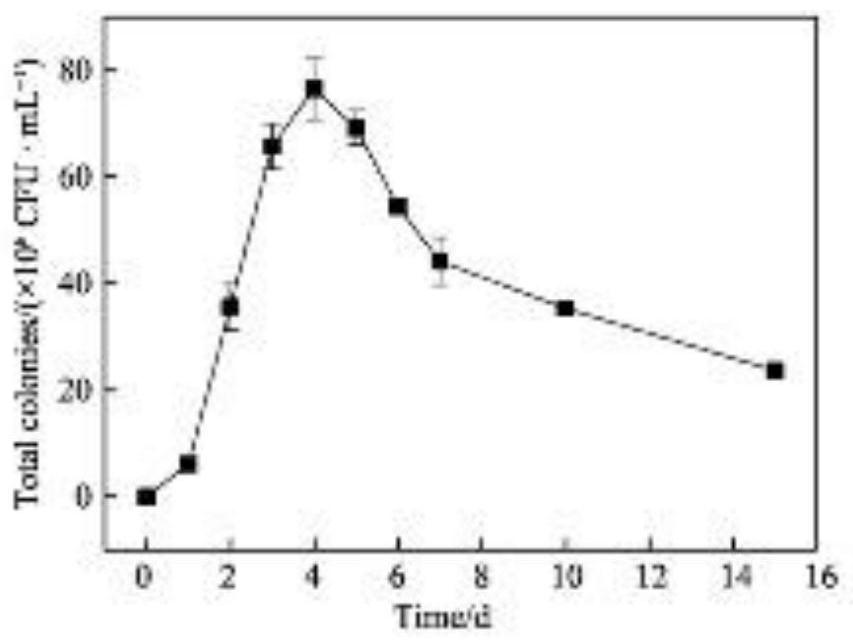

Embodiment 1

[0023] This embodiment provides an environment-friendly water-soluble metal processing cutting fluid, including: 20.0% to 40.0% of self-emulsifying synthetic fat (the mass fraction of self-emulsifying synthetic fat in this embodiment is 26.0%), 20.0% to 30.0% of di Carboxylic acid (in this embodiment, dicarboxylic acid mass fraction is 25.0%), 25.0%~35.0 pH regulator (in this embodiment, pH regulator mass fraction is 25.0%), 5.0%~25.0% Demineralized water (in this embodiment, the mass fraction of demineralized water is 10.0%), 0.5%~5% dodecylguanidine hydrochloride (in this embodiment, the massfraction of dodecylguanidine hydrochloride is 2.0%), 3.0 %~10.0% alcohol ether carboxylic acid (the mass fraction of alcohol ether carboxylic acid in this embodiment is 12.0%).

[0024] The preparation method of the above-mentioned environment-friendly water-soluble metalworking cutting fluid comprises the following steps:

[0025] Step 1: Configure self-emulsifying synthetic fat, dicar...

Embodiment 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that a kind of environment-friendly water-soluble metalworking cutting fluid comprises: 26.0% self-emulsifying synthetic fat, 25.0% dicarboxylic acid, 25.0% pH regulator, 10.0% demineralized water, 3.2% dodecylguanidine hydrochloride, 11.8% alcohol ether carboxylic acid.

Embodiment 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 is that an environment-friendly water-soluble cutting fluid for metal processing includes: 26.0% self-emulsifying synthetic fat, 25.0% dicarboxylic acid, 25.0% pH regulator, 10.0% demineralized water, 4.0% dodecylguanidine hydrochloride, 10% alcohol ether carboxylic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com