A new material tensile strength testing equipment

A technology for testing equipment and tensile strength, which is used in the application of stable tension/pressure to test the strength of materials, analyze materials, strength characteristics, etc. problems, to achieve the effect of prolonging the service life, preventing debris from splashing, and preventing the material from slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments of the description. For the step numbers in the embodiment of the present invention, it is only set for the convenience of explanation and description, and there is no limitation on the order of the steps. The execution order of each step in the embodiment can be carried out according to the understanding of those skilled in the art Adaptive adjustments:

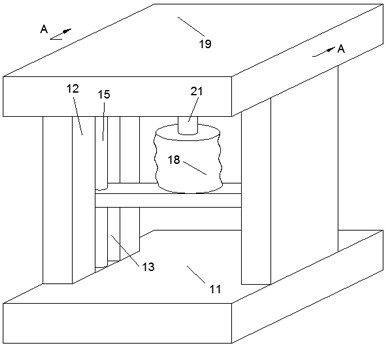

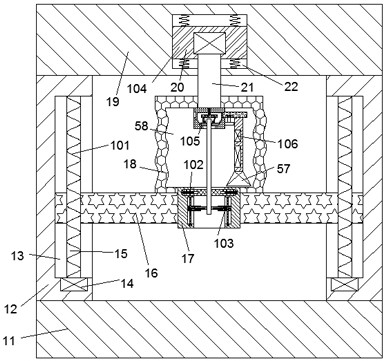

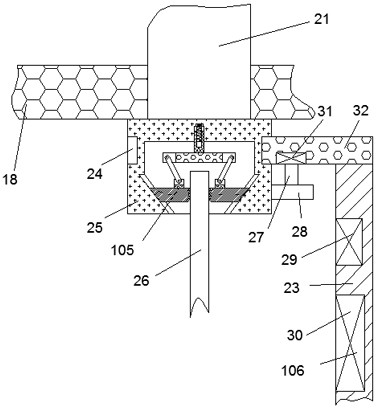

[0036] Refer to attached Figure 1-6 , a new material tensile strength testing device according to an embodiment of the present invention, comprising a body casing 11, the top wall of the body casing 11 is fixed with left and right symmetrical support blocks 12, and the support blocks 12 are provided with The tension beam 16, the support block 12 is provided with a power device 101 capable of moving the tension beam 16 up and down, the tension beam 16 is fixed with a first fixed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com