Electromagnetic dielectric material sheet, electromagnetic dielectric particle and production method thereof

A technology of dielectric particles and production methods, which is applied in the production of electromagnetic dielectric particles, electromagnetic dielectric particles, and electromagnetic dielectric material sheets, which can solve the problem of affecting the dielectric constant of Lunberg lenses, difficulty in production, and easy waste, etc. problem, to achieve the effect of no obvious directivity, high production efficiency, and accurate dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

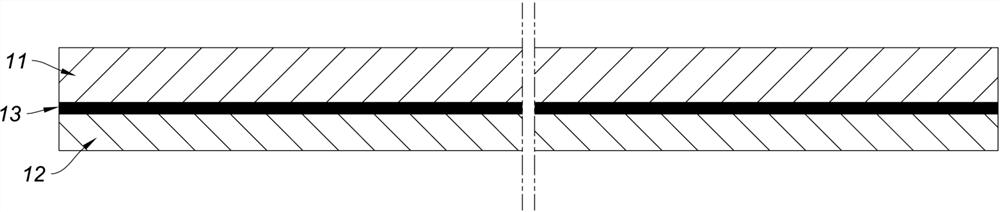

[0048] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present embodiment is an electromagnetic dielectric material sheet, comprising a first foam material layer 11, a second foam material layer 12 and a film layer 13, and the film layer 13 is clamped and fixed on the first foam material layer. Between the material layer 11 and the second foam material layer 12;

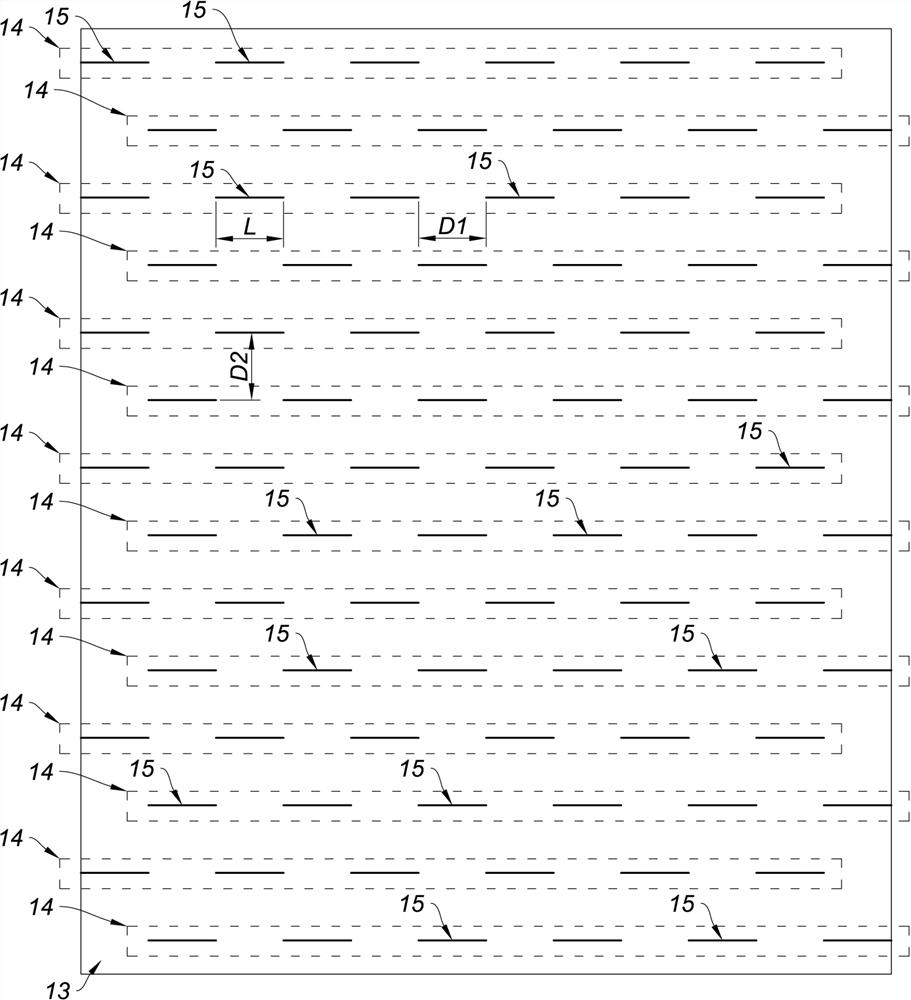

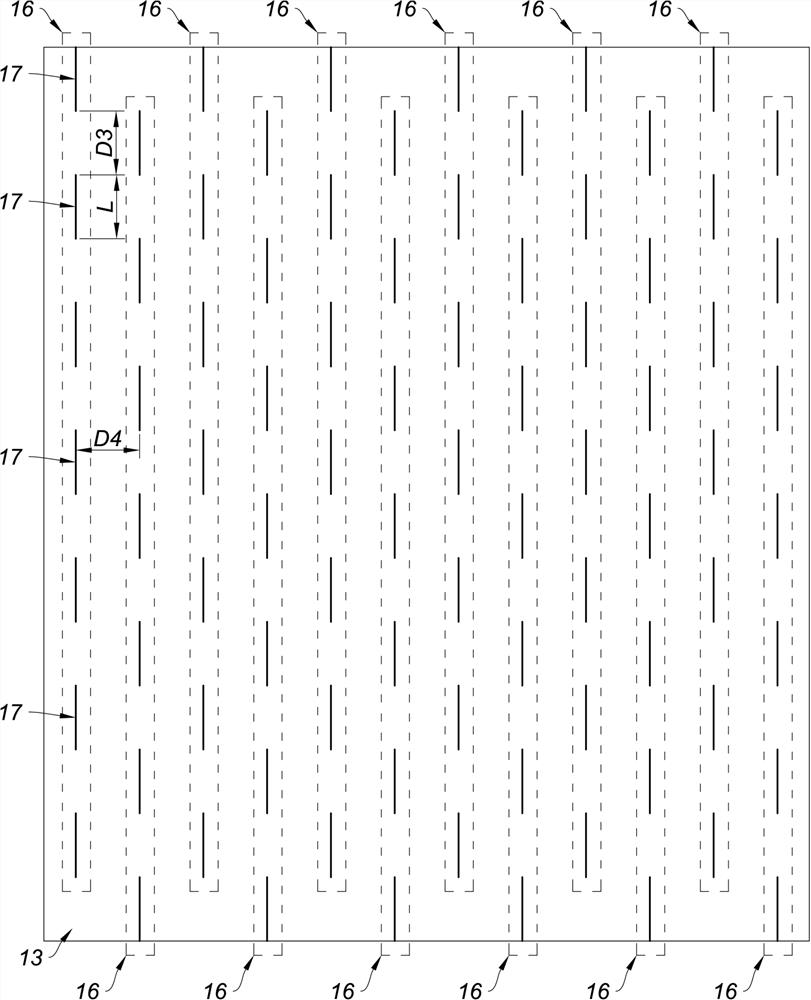

[0049] Several first conductor groups 14 are arranged on the front surface of the film layer 13, and each first conductor group 14 includes a plurality of first conductors 15, the first conductor 15 is a filamentous structure, and the first conductor 15 is a filamentous structure. The thickness of the design is negligible, the length of the first conductor 15 is L, 0.1mm≤L≤N*λ, N is in the range of 0.1-0.3, and λ is in the range of 9mm-100mm; the same first conductor group The central axes of the first conductors 15 in 14 are collinearly spaced and arranged, and the common line is called the tra...

Embodiment 2

[0055] The difference between this embodiment and embodiment 1 is: as Figure 6 As shown, in this embodiment, the first conductor 22 and the second conductor 23 constituting one conductor unit 21 do not intersect at the midpoint of their respective length directions. The reason for this situation is generally that the starting point of printing is not set when printing the first conductor 22 or the second conductor 23 during the production process, so that the printing is offset, and only the first conductor unit 21 in the same conductor unit 21 The conductor 22 and the second conductor 23 can also maintain the intersecting state, although the dielectric constant directivity of the electromagnetic dielectric particles formed by cutting the electromagnetic dielectric material sheet with such a structure is slightly worse than that of embodiment 1, it will not affect the use. Effect.

Embodiment 3

[0057] Such as Figure 7 As shown, this embodiment is an electromagnetic dielectric particle, including a particle body 31. The particle body 31 is made of the electromagnetic dielectric material sheet described in Embodiment 1 through horizontal cutting and vertical cutting. In this embodiment, the horizontal cutting The spacing between vertical cutting and vertical cutting is 2L. This embodiment is cut according to the standard law in Example 1. The spacing between horizontal cutting and vertical cutting is 2L, which is a limit state. In practical applications, only horizontal cutting The spacing with the vertical cutting is a positive integer multiple of L, so that the particle body 31 formed by cutting includes at least a first conductor 32 of a complete length and a second conductor 33 of a complete length. The particle body 31 of this embodiment Specifically, it includes 2 complete first conductors 32 and 2 complete second conductors 33 . During use, such as Figure 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com