A kind of foamed Lumber lens and its preparation process

A preparation process and lens technology, applied in additive processing, antennas, electrical components, etc., can solve the problems of complex preparation process, inability to ensure the accuracy of the dielectric constant of each layer, and the heavy weight of Lunbo lenses, and achieve uniform structure, Avoid multi-layer foaming, the effect of accurate dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment provides a kind of preparation method of foamed Lumber lens, uses polypropylene (ε A =2.3) As a resin material, barium titanate (ε B =1400) as a dielectric regulator, the specific steps are as follows:

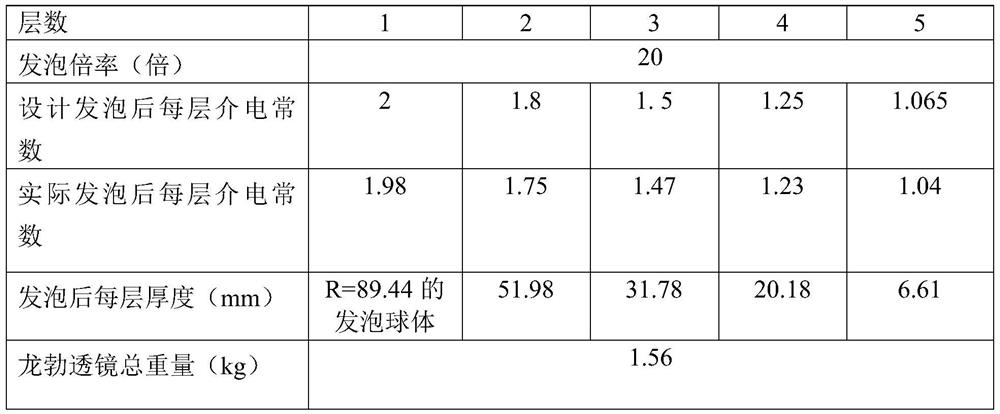

[0028] (1) Confirm that the preparation radius R=200mm, foaming magnification n=20 foaming Lunbo lens, its number of layers m=5, the dielectric constant of each layer after setting foaming is respectively: ε 1 = 2, ε 2 = 1.8, ε 3 = 1.5, ε 4 = 1.25, ε 5 = 1.065;

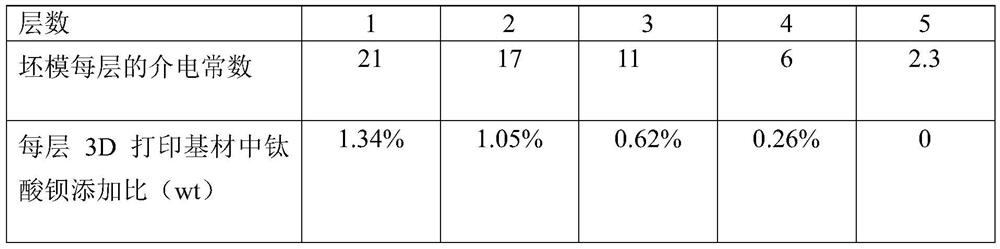

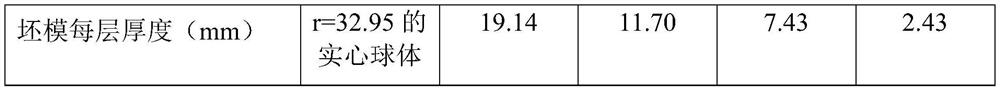

[0029] (2) According to ε i ’=n×(ε i -1)+1 and δ i =[R×(2-ε i+1 ) 1 / 2 -R×(2-ε i ) 1 / 2 】 / n 1 / 3 , and the first layer r 1 =[R×(2-ε 2 ) 1 / 2 】 / n 1 / 3 , the mth layer thickness δ m= 【R-R×(2-ε m ) 1 / 2 】 / n 1 / 3 , to obtain the information of the spherical blank mold to be prepared, as shown in Table 1 below:

[0030] The spherical blank mold data that needs to be prepared in the embodiment 1 of table 1

[0031]

[0032]

[0033] (3) Configure the 3D printing substrate ...

Embodiment 2

[0039] The present embodiment provides a kind of preparation method of foamed Lumber lens, uses polypropylene (ε A =2.3) As a resin material, barium titanate (ε B =1400) as a dielectric regulator, the specific steps are as follows:

[0040] (1) Confirm that the preparation radius R=500mm, the foaming Lumber lens of foaming magnification n=25, its number of layers m=9, the dielectric constant of each layer after setting foaming is respectively: ε 1 = 2, ε 2 = 1.9, ε 3 = 1.75, ε 4 = 1.6, ε 5 = 1.45, ε 6 = 1.3, ε 7 = 1.2, ε 8 = 1.1, ε 9 = 1.052;

[0041] (2) According to ε i’=n×(ε i -1)+1 and δ i =[R×(2-ε i+1 ) 1 / 2 -R×(2-ε i ) 1 / 2 】 / n 1 / 3 , and the first layer r 1 =[R×(2-ε 2 ) 1 / 2 】 / n 1 / 3 , the mth layer thickness δ m= 【R-R×(2-ε m ) 1 / 2 】 / n 1 / 3 , to obtain the information of the spherical base mold that needs to be prepared, as shown in Table 3 below:

[0042] The spherical blank mold data that needs to be prepared in the embodiment 2 of table 3

[0043...

Embodiment 3

[0050] The present embodiment provides a kind of preparation method of foamed Lumber lens, uses polypropylene (ε A =2.3) As a resin material, titanium dioxide (ε B =114) as a dielectric regulator, the specific steps are as follows:

[0051] (1) Confirm that the preparation radius R=1000mm, the foaming Lumber lens of foaming magnification n=30, its layer number m=7, the dielectric constant of each layer after setting foaming is respectively: ε 1 = 2, ε 2 = 1.75, ε 3 = 1.53, ε 4 = 1.35, ε 5 = 1.2, ε 6 = 1.1, ε 7 = 1.04;

[0052] (2) According to ε i ’=n×(ε i -1)+1 and δ i =[R×(2-ε i+1 ) 1 / 2 -R×(2-ε i ) 1 / 2 】 / n 1 / 3 , and the first layer r 1 =[R×(2-ε 2 ) 1 / 2 】 / n 1 / 3 , the mth layer thickness δ m= 【R-R×(2-ε m ) 1 / 2 】 / n 1 / 3 , to obtain the information of the spherical base mold that needs to be prepared, as shown in Table 5 below:

[0053] The spherical blank mold data that needs to be prepared in the embodiment 3 of table 5

[0054]

[0055]

[0056] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com