New energy wiring harness plugging structure

A plug-in structure and new energy technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problems of limited adaptation and inconvenient use, and achieve improved reliability, wide application range, and convenient disassembly. The effect of pretending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

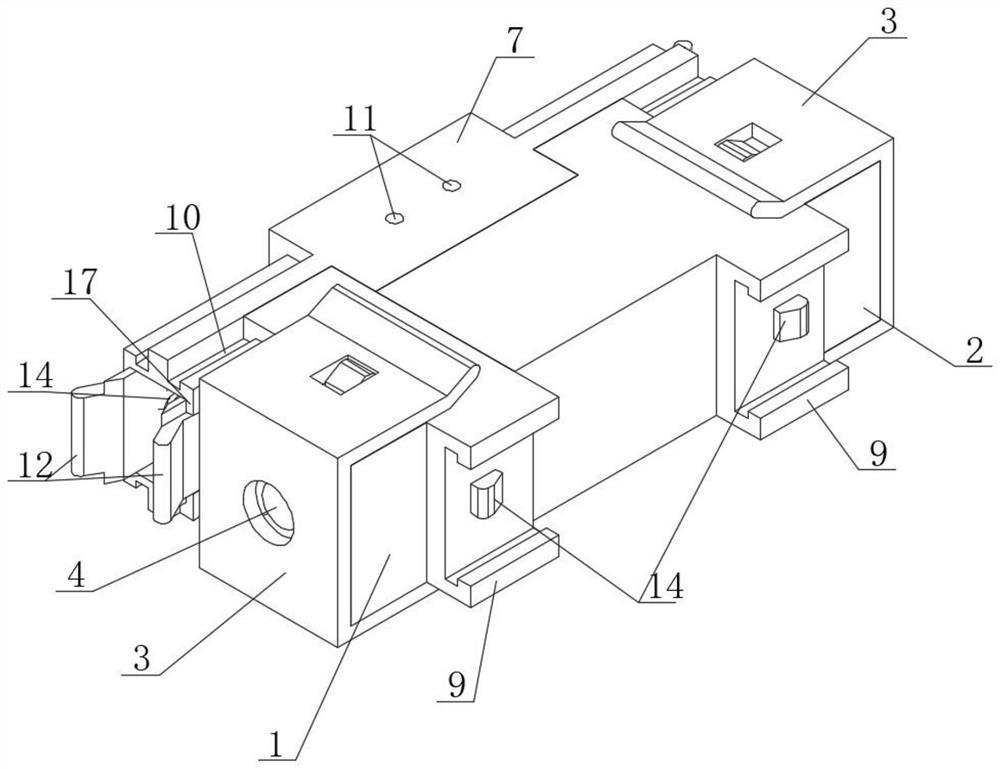

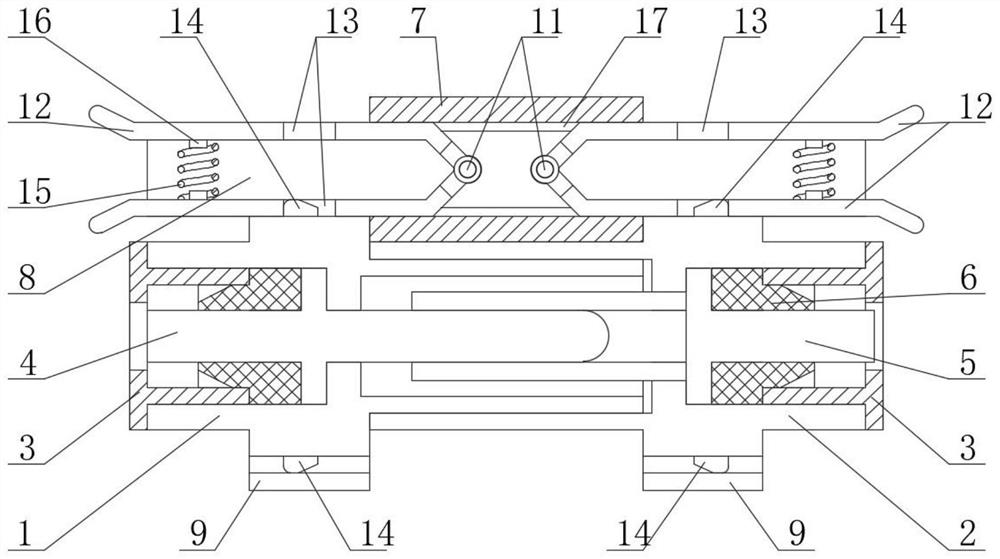

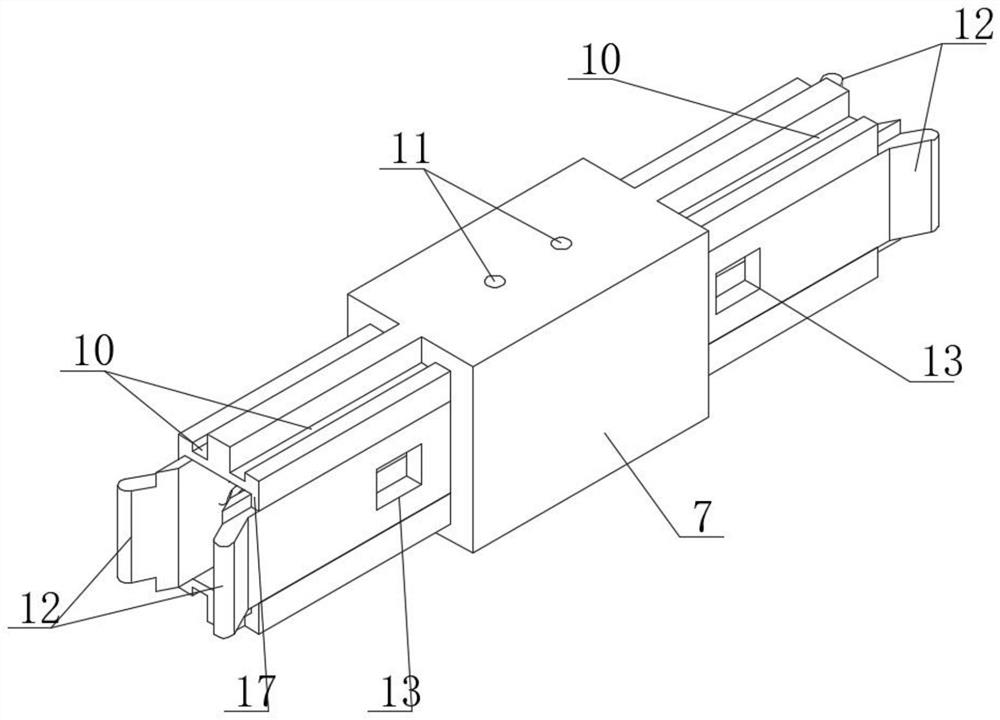

[0020] See Figure 1-4 The present invention provides a technical solution: a new energy harness plug structure, including correspondingly inserted male terminals 1 and the female end 2 and a connecting shell disposed between the male terminal 1 and the female end 2, specifically, The male terminal 1 extends to one end of the female end 2 as a member, and the mid-end 2 is formed in one end of the male terminal 1, and the male end 1 and the female end 2 are detachable in the male end 1 and the female end 2, respectively. There is a pin 4 and the socket 5, the pin 4 corresponds to the socket 5, in particular, the pin 4 is fitted with the socket 5 shaft hole, and the two ends of the connecting case 7 are provided with the male end 1 and the female end. 2 Slide the guide plate 8, the central detachable connection of the inner cavity of the connecting case 7, in particular, the positioning pin 11 penetrates the connecting case 7, and the positioning pin 11 is respectively connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com