Ammonium phosphate salt dry powder extinguishing agent and preparation method thereof

A dry powder fire extinguishing agent, ammonium phosphate technology, applied in fire protection equipment and other directions, can solve the problems of difficult filling of fire extinguishers and fire protection systems, and the reduction of fire extinguishing effect of dry powder fire extinguishing agents, so as to improve fire extinguishing efficiency, improve bulk density, and reasonable particle size structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

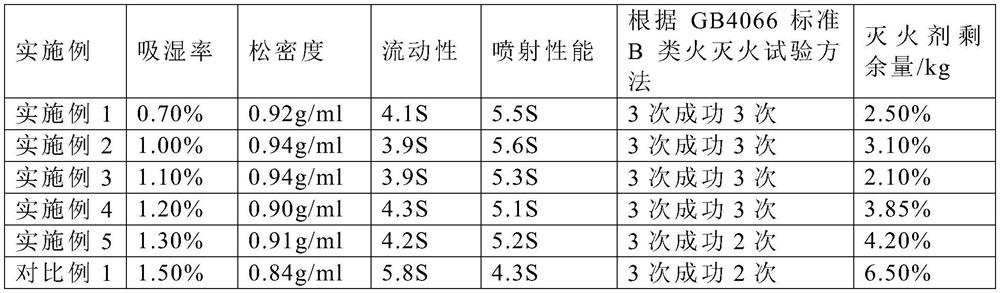

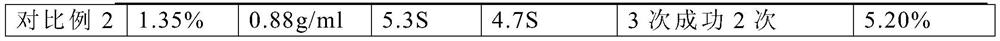

Examples

Embodiment 1

[0037] Weigh 750 kg of ammonium dihydrogen phosphate, 150 kg of ammonium sulfate, 30 kg of mica powder, 30 kg of activated clay, 20 kg of hydrophobic white carbon black, 15 kg of silicone oil, 20 kg of water, and 20 kg of talcum powder.

[0038] (1) 5kg silicone oil, 5kg hydrophobic white carbon black and 380kg ammonium dihydrogen phosphate are mixed homogeneously, and main raw material pulverized material 1; 5kg silicone oil, 5kg hydrophobic white carbon black are mixed with 370kg ammonium dihydrogen phosphate and 150kg ammonium sulfate, Crushed material 2 as the main raw material;

[0039] (2) pulverize the main raw material pulverized material 1 after pre-siliconization with an ultrafine pulverizer, so that the particle size after pulverization satisfies D90 between 10-15 microns; Pulverized material 2 is pulverized to meet the requirement that the particle size D90 is between 80-100 microns;

[0040] (3) Put the pulverized main raw material pulverized material 1, main raw...

Embodiment 2

[0043] Weigh 700kg of ammonium dihydrogen phosphate, 200kg of ammonium sulfate, 40kg of mica powder, 20kg of activated clay, 25kg of hydrophobic white carbon black, 20kg of silicone oil, 25kg of water, and 15kg of talcum powder.

[0044] (1) 6kg silicone oil, 7kg hydrophobic white carbon black and 390kg ammonium dihydrogen phosphate are mixed homogeneously, and main raw material pulverized material 1; 6kg silicone oil, 7kg hydrophobic white carbon black are mixed with 310kg ammonium dihydrogen phosphate and 200kg ammonium sulfate, Crushed material 2 as the main raw material;

[0045] (2) pulverize the main raw material pulverized material 1 after pre-siliconization with an ultrafine pulverizer, so that the particle size after pulverization satisfies D90 between 10-15 microns; Pulverized material 2 is pulverized to meet the requirement that the particle size D90 is between 80-100 microns;

[0046] (3) Put the pulverized main raw material pulverized material 1, main raw materia...

Embodiment 3

[0049] Weigh 700kg of ammonium dihydrogen phosphate, 150kg of ammonium sulfate, 30kg of mica powder, 40kg of activated clay, 30kg of hydrophobic white carbon black, 25kg of silicone oil, 30kg of water, and 50kg of talcum powder.

[0050] (1) 7kg silicone oil, 8kg hydrophobic white carbon black and 420kg ammonium dihydrogen phosphate are mixed homogeneously, and main raw material pulverized material 1; 7kg silicone oil, 8kg hydrophobic white carbon black are mixed with 280kg ammonium dihydrogen phosphate and 150kg ammonium sulfate, Crushed material 2 as the main raw material;

[0051] (2) pulverize the main raw material pulverized material 1 after pre-siliconization with an ultrafine pulverizer, so that the particle size after pulverization satisfies D90 between 10-15 microns; Pulverized material 2 is pulverized to meet the requirement that the particle size D90 is between 80-100 microns;

[0052] (3) Put the pulverized main raw material pulverized material 1, main raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com