Luminous sunshade curtain cloth assembly

A technology of sunshade and assembly, applied in the field of light-emitting sunshade cloth assembly, can solve the problems of unfavorable guide rail composition and installation, poor light conduction effect, poor light output effect, etc., and achieves increased lighting effect, economical convenience, and guarantee The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Such as Figure 11 As shown, as the composition of the strong light section 6 and the weak light section 7, the light-concentrating parts 5.1 are arranged at intervals on the light guide unit 5, and the strong light section 6 is formed at the light-condensing parts 5.1. Bright light effect, and weak light sections 7 are formed on both sides of the light-concentrating part 5.1, so that a gradual light emission is formed on the curtain 2 without controlling the light-emitting components.

[0044] In some other embodiments, the positions of the light-gathering parts 5.1 on each light-guiding unit 5 are random, so that a dotted light-emitting effect is formed on the curtain 2 to increase driving experience.

[0045] Among them, by adjusting the light source 9, various light emitting effects can also be realized on the body of the curtain 2, such as constant light, flashing, breathing, rhythm of music, etc. as examples.

[0046] Such as Figure 6 to Figure 8 As shown, as a...

Embodiment 2

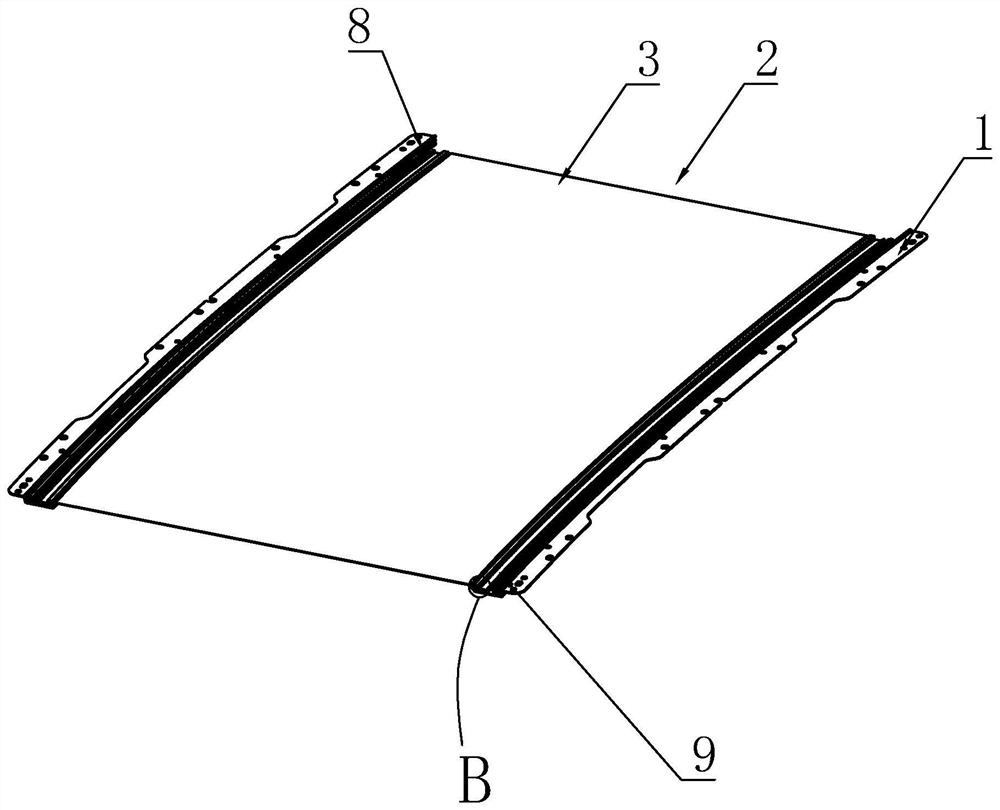

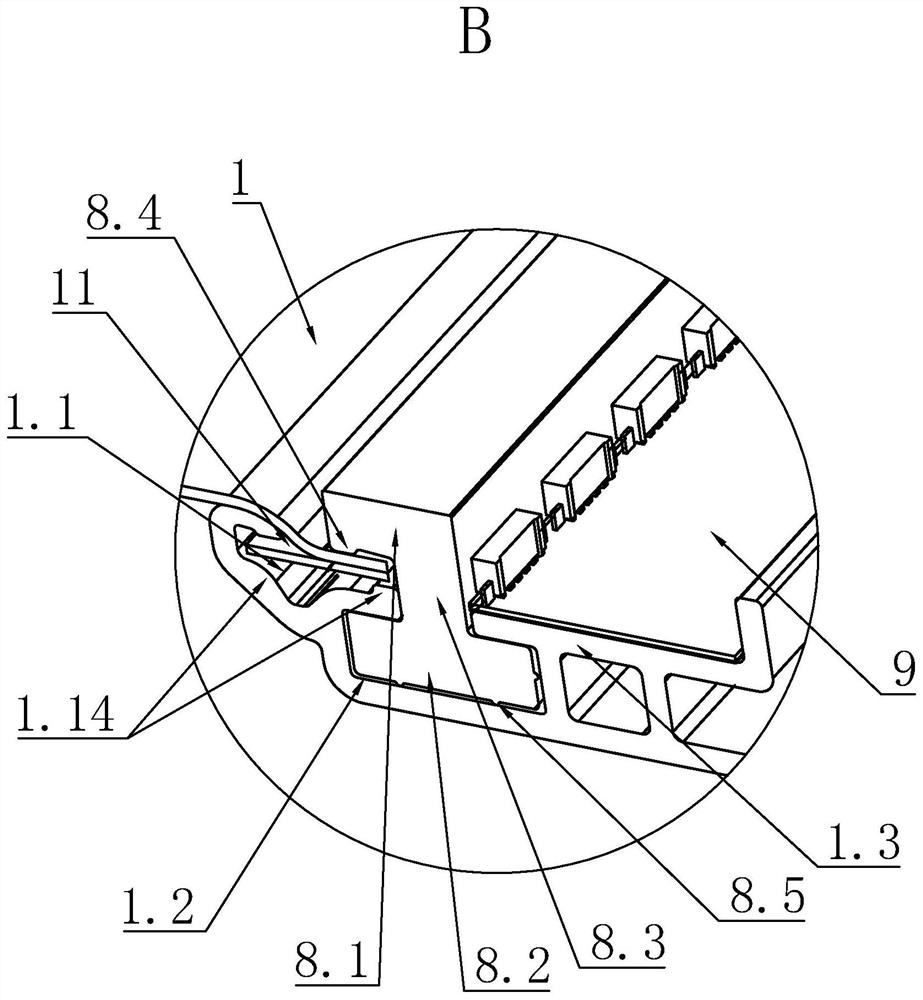

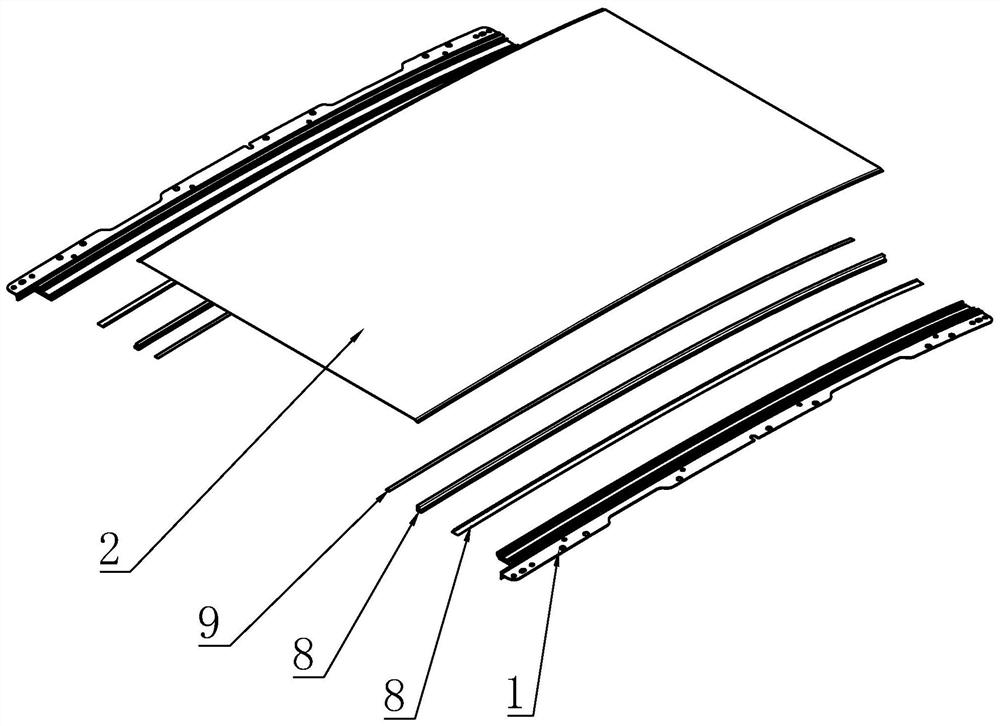

[0052] Such as Figure 4 and Figure 9 As shown, in order to increase the stability of the curtain 2 sliding in the guide seat 1.1, a side strip 11 is provided at the bottom of the outer side 2.1 of the curtain 2, and the side strip 11 enters the guide seat 1.1 along with the outer side 2.1, thereby Instead of friction between the outer edge 2.1 and the guide seat 1.1, the outer edge 2.1 is prevented from being worn, and the service life of the cord 2 is increased. As a fixing method, the edge strip 11 and the outer edge 2.1 are connected by sewing.

[0053] The side strip 11 has a connection part 11.1 entering the light guide area 10 and a detachment prevention part 11.2, the detachment prevention part 11.2 is away from the light guide 8, and the detachment prevention part 11.2 and the connection part 11.1 are connected by stitching 11.3, the connecting part is integrally connected with the outer side 2.1, and the anti-off part 11.2 can be disengaged with the outer side 2.1 ...

Embodiment 3

[0056] Such as Figure 4 and Figure 5 As shown, as a specific explanation of the structure of the light guide 8, the light guide 8 also includes a mounting part 8.2 constrained in the receptacle 1.2 and an adjoining part 8.3 for coupling light, and the limiting member 8.1 faces The curtain 2 extends above the guide cavity, the adjoining portion 8.3 is a vertical wall structure, the installation portion 8.2 is a horizontal wall structure, the installation portion 8.2 is formed on the bottom of the adjoining portion 8.3, and the limiting member 8.1 It is formed on the top of the adjoining part 8.3, so that the adjoining part 8.3 and the mounting part 8.2 form a "⊥"-shaped structure, and the outline of the receptacle 1.2 corresponds to the "⊥" shape, so as to limit the light guide strip in the receptacle 1.2 Play vertically and widthwise.

[0057] Specifically, the light guide member 8 is provided with protrusions in the circumferential direction, and the protrusions elastical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com