PID control performance comprehensive evaluation method considering uncertainty

A control performance and comprehensive evaluation technology, applied to controllers with specific characteristics, electric controllers, etc., can solve problems such as difficult to reflect the level of mechanism control performance, and achieve the effect of improving credibility

- Summary

- Abstract

- Description

- Claims

- Application Information

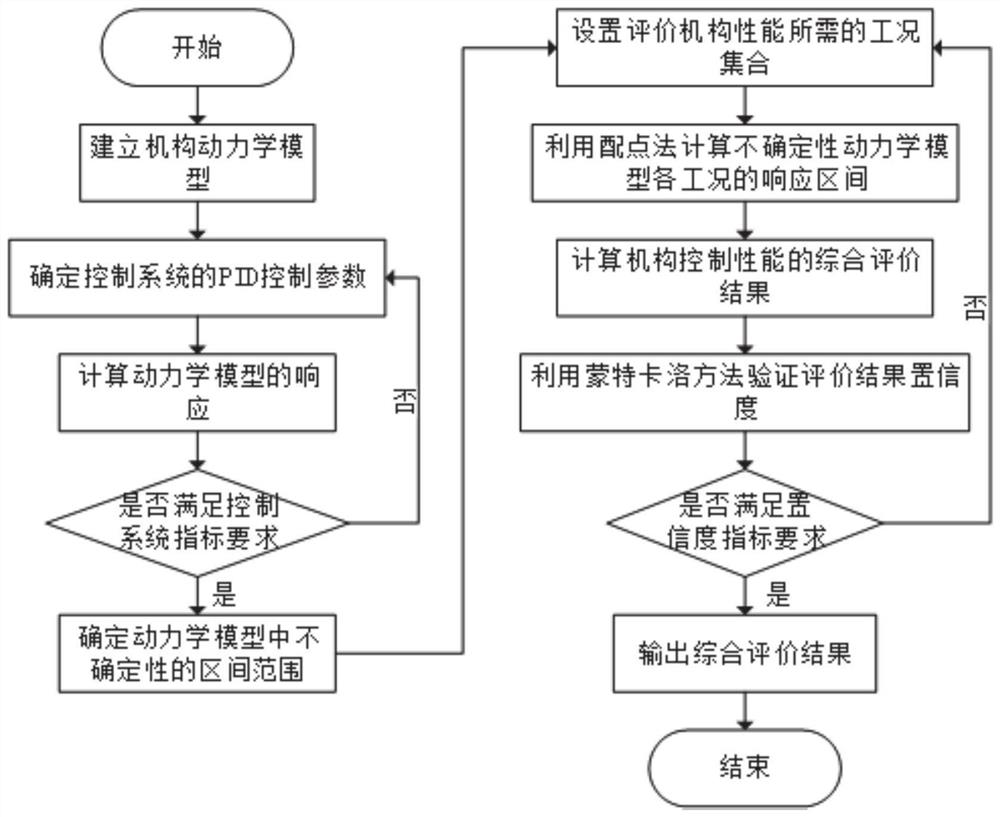

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

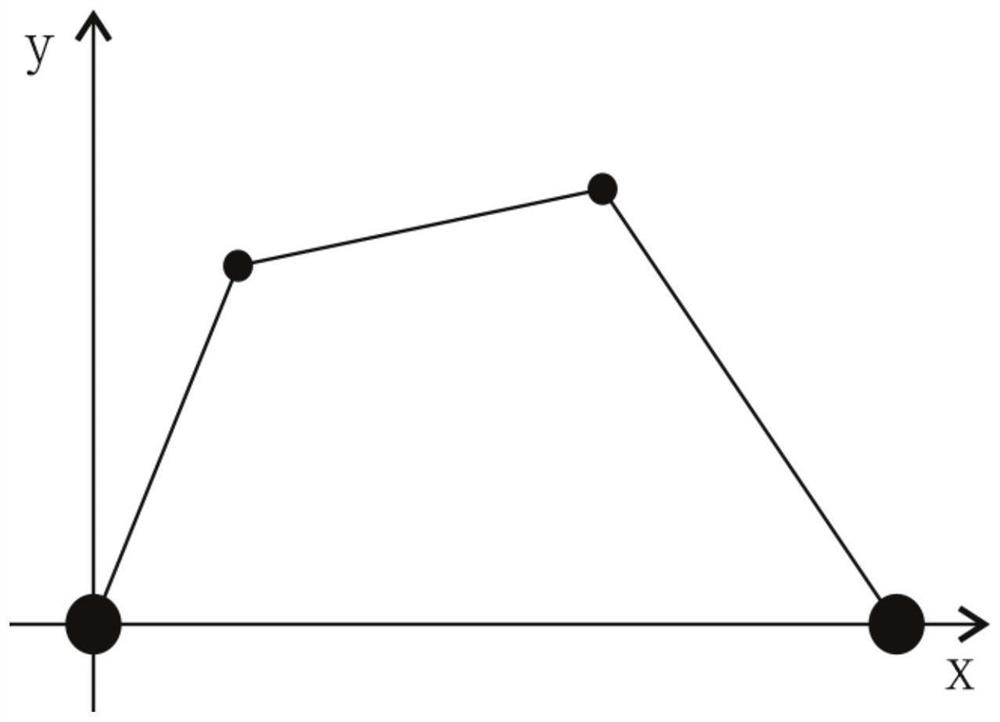

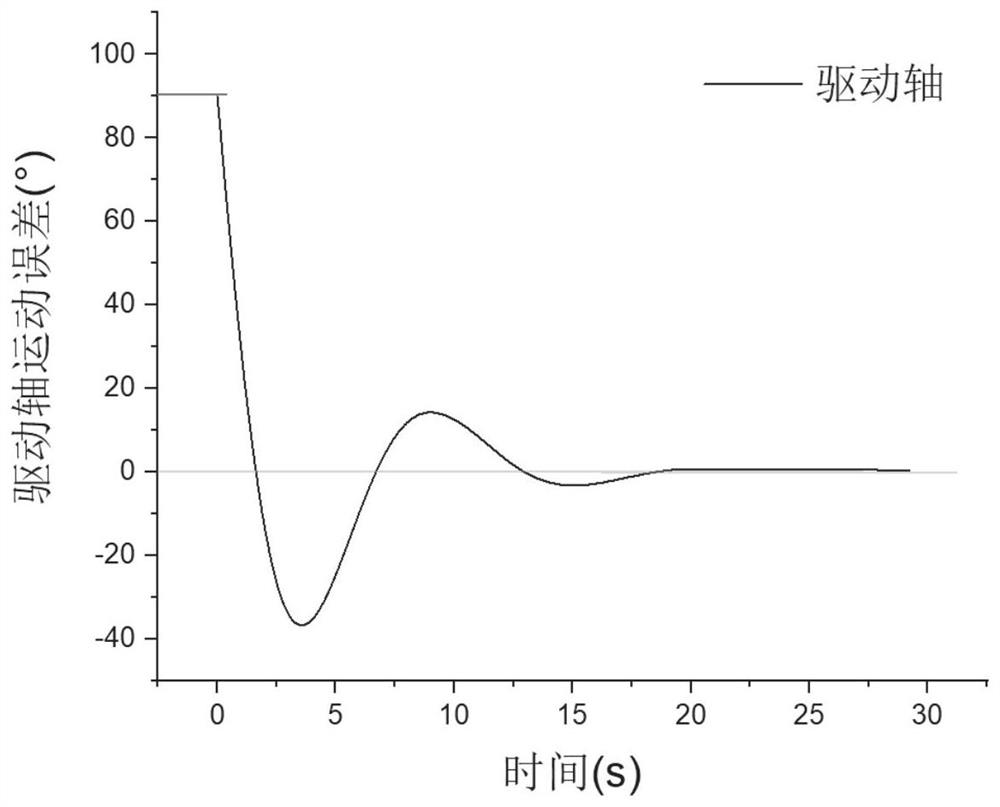

[0054] Such as figure 2 As shown, it is a planar four-bar linkage mechanism with a single degree of freedom. Axis 1 is the driving shaft, on which driving torque is applied. The lengths of the connecting rods are 55mm, 73mm, 135mm and 145mm respectively, and the mass of each connecting rod is m=1kg , the moment of inertia is 0.01kgm 2 . The operating condition is that axis 1 rotates 90°, and the angular response of mechanism axis 1 is as follows image 3 As shown, the motion error of the planar four-bar linkage mechanism gradually decreases with the movement process, and the angle of the axis 1 of the planar four-bar linkage mechanism gradually tends to the target value. The gain in the system controller is obtained through the iterative optimization calculation of the sequential quadratic programming algorithm The coefficient is: K P =5.13,K I =1.81, K D = 0.83.

[0055] To further introduce uncertainty into the mechanism system, the length and mass of each rod in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com