Heavy lifting support

A lifting bracket, heavy-duty technology, applied in the direction of lifting devices, etc., can solve the problems of inconvenient operation, heavy volume, etc., and achieve the effect of easy movement, reasonable structural design and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

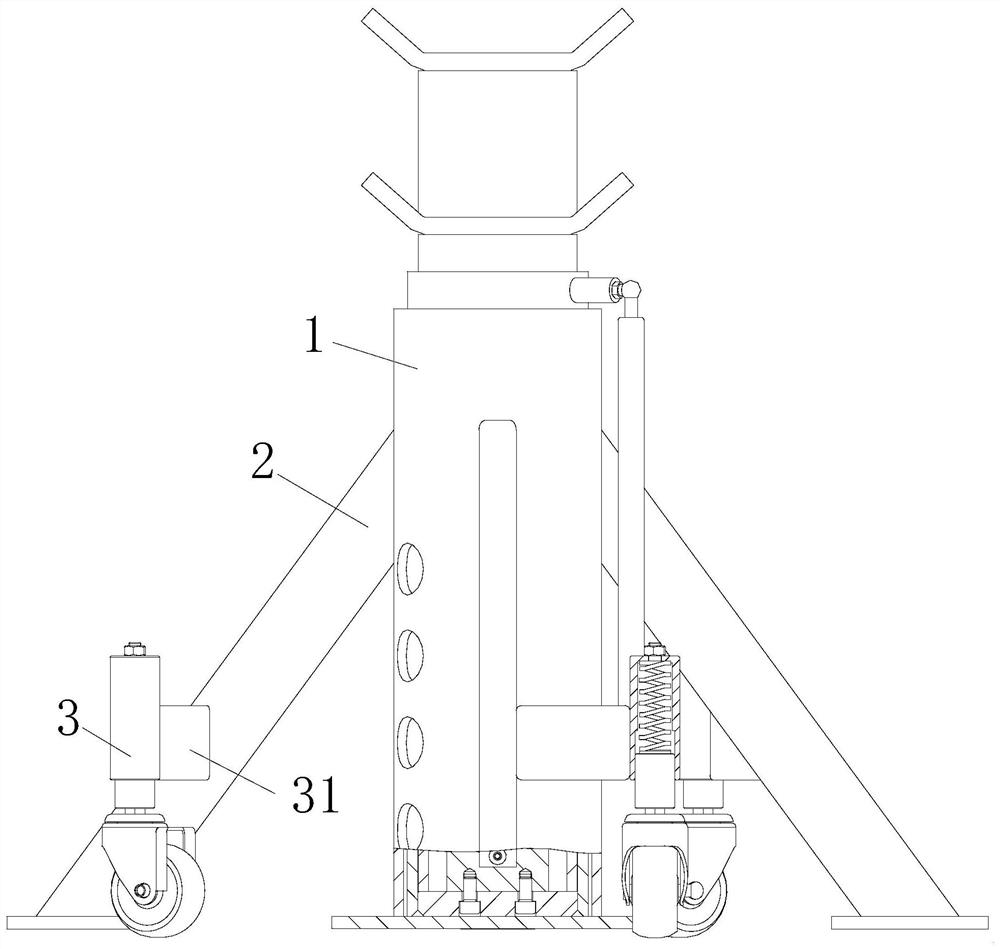

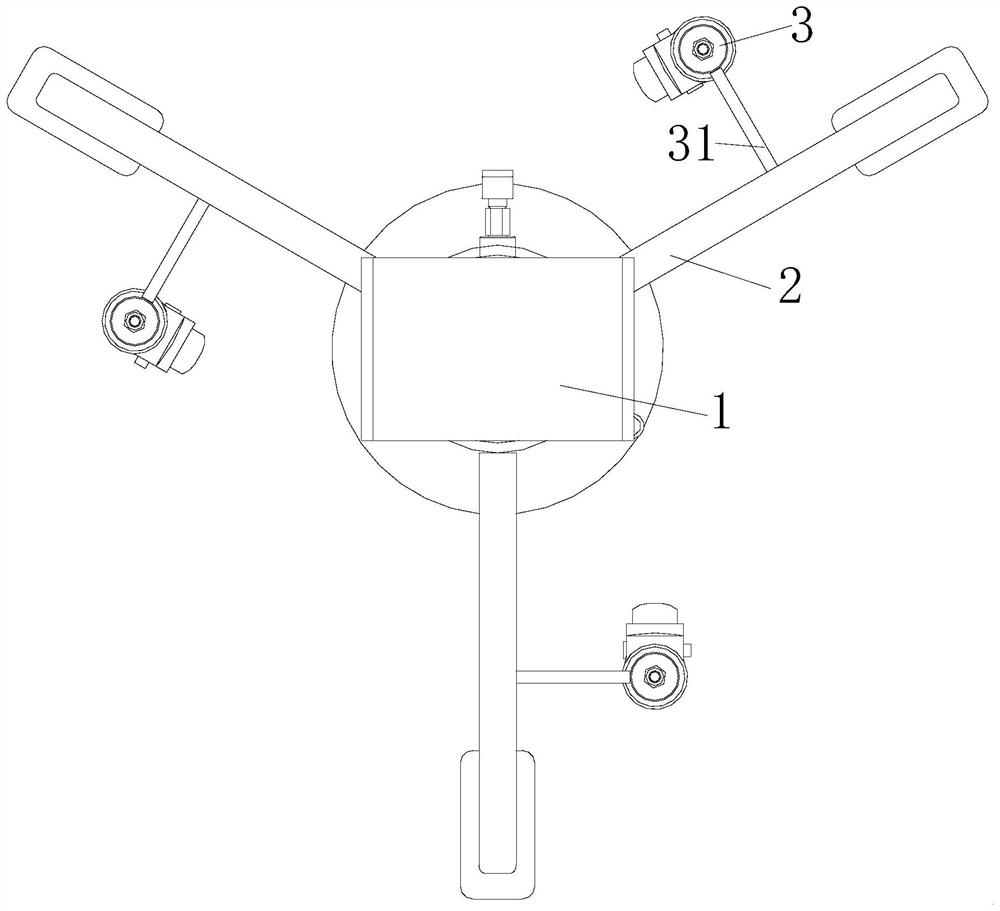

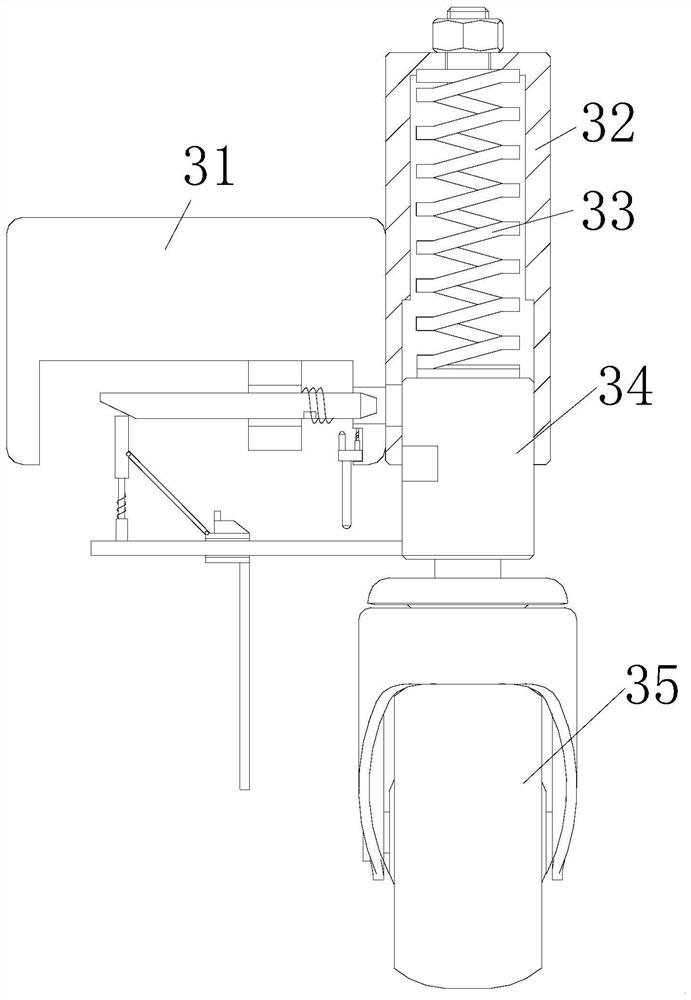

[0032] Attached below Figure 1-6 The present invention is further described with embodiment:

[0033] The heavy-duty lifting bracket includes a hydraulic heavy lifting body 1 and a triangular support column 2. Three triangular support columns 2 are arranged equidistantly on the circumference of the hydraulic heavy lifting body 1, and a moving mechanism 3 is arranged on each of the three triangular support columns 2. A fixed sleeve is movably inserted into the heavy lifting body 1, and a gas spring is hinged outside the fixing sleeve. Universal wheels are added to the hydraulic heavy-duty lifting bracket, so that the hydraulic heavy-duty lifting bracket can move conveniently when the hydraulic heavy-duty lifting bracket is unloaded, and the structure of the universal wheel in the equipment is reasonable and has Scalable performance, so that when weighing and lifting heavy objects, it can prevent the universal wheel from moving. When it is empty, it can support the hydraulic h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com