Efficient textile sueding equipment

A technology of sanding and equipment, applied in textiles and papermaking, etc., can solve problems such as health damage, reduce efficiency, waste time, etc., and achieve the effect of ensuring health, reducing air pollution, and ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

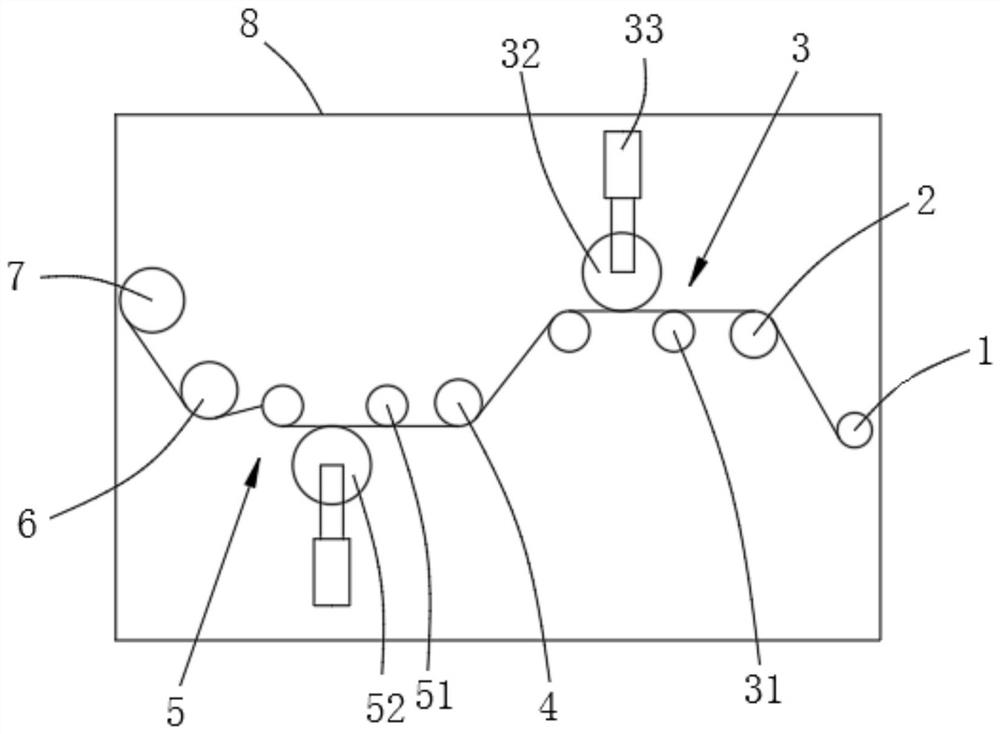

[0021] Embodiment: a kind of high-efficiency textile sanding equipment, such as Figure 1-Figure 2 As shown, the textile sanding equipment sequentially includes an unwinding roller 1, a first guide roller 2, a first sanding mechanism 3, a second guide roller 4, a second sanding mechanism 5, and a third roller along the direction of product conveyance. Guide roller 6 and winding roller 7;

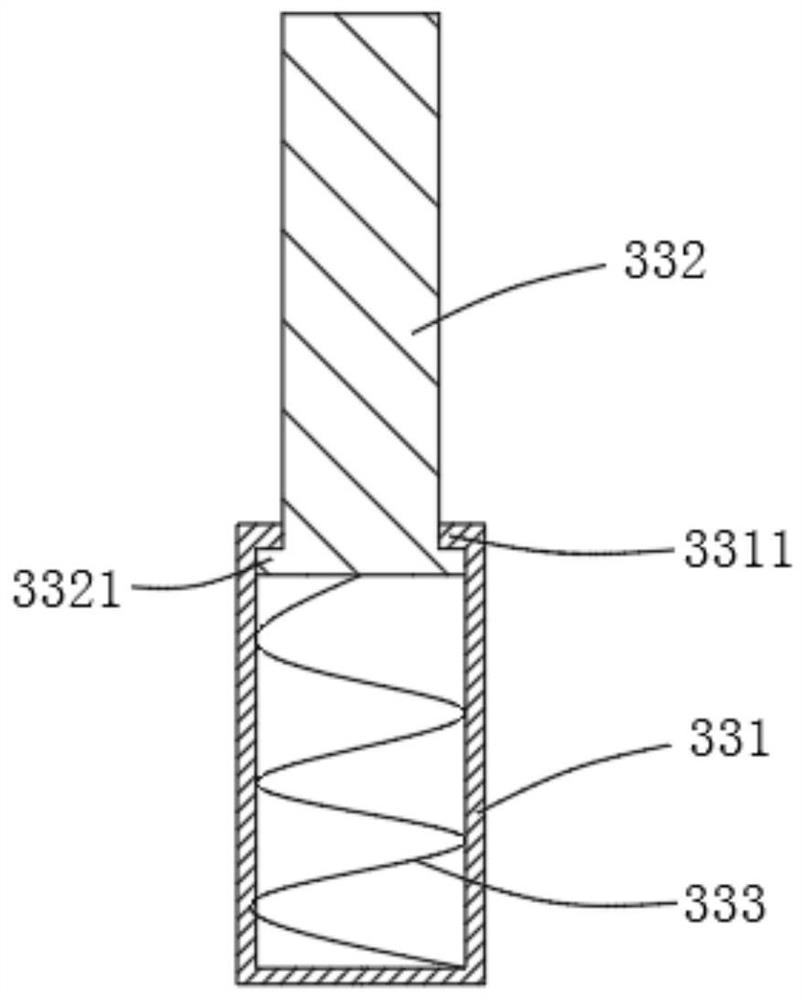

[0022] The first sanding mechanism 3 includes two lower pressing rollers 31 and a first elastic sanding roller 32 between the two lower pressing rollers 31, and the first elastic sanding roller 32 is located on the lower pressing roller 31 above, and the product is located between the first elastic sanding roller 32 and the lower pressure roller 31, the first elastic sanding roller 32 is connected with the first elastic support tube 33;

[0023] The second sanding mechanism 5 includes two upper pressing rollers 51 and a second elastic sanding roller 52 between the two upper pressing rollers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com