Single-side loading type large compression-shear-bending composite loading test device and application thereof

A composite loading and testing device technology, applied in the direction of testing material strength by applying stable bending force, testing material strength by applying stable shear force, testing material strength by applying repetitive force/pulsation force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

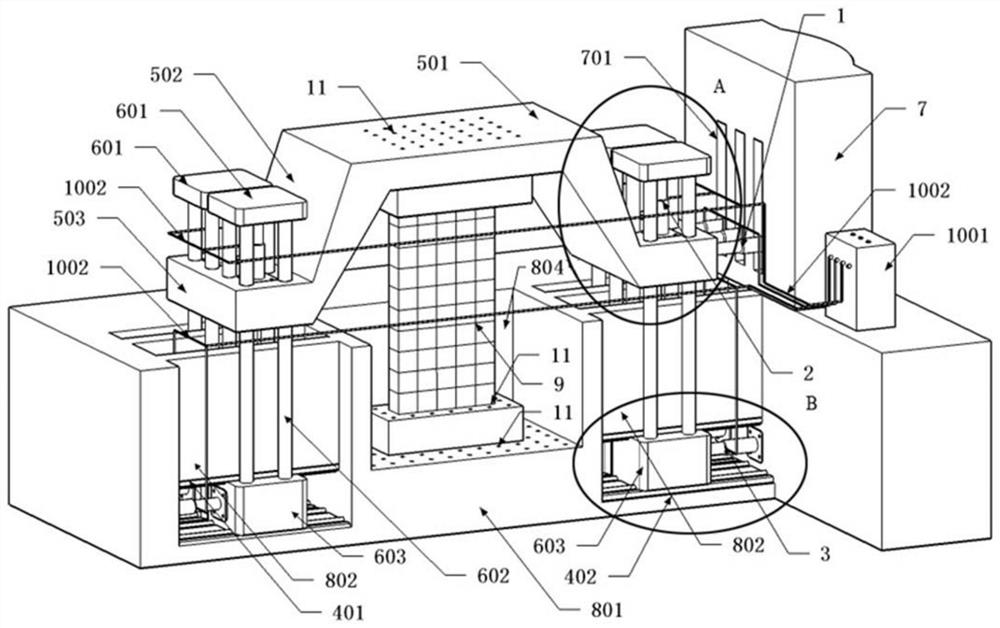

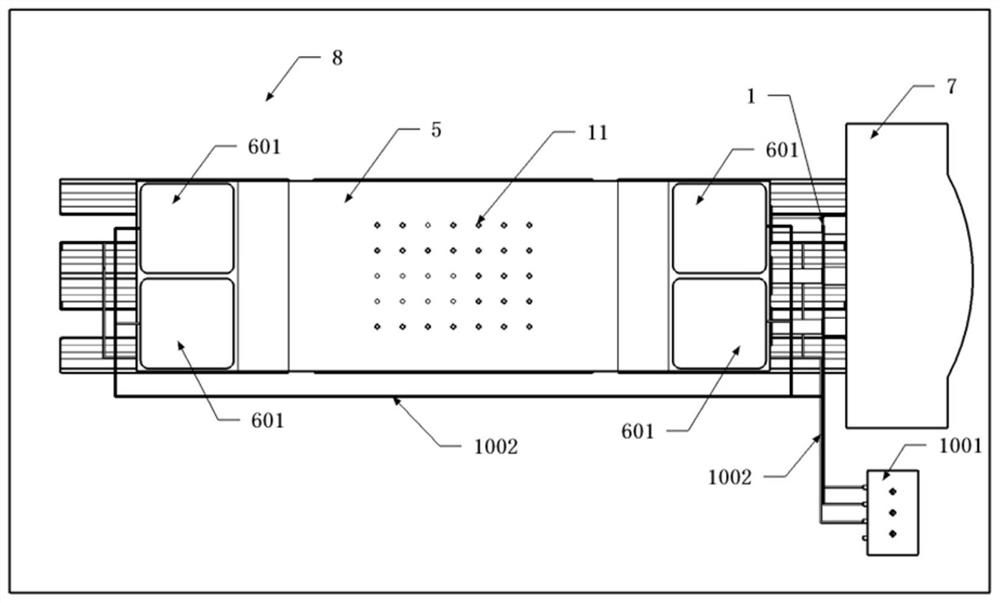

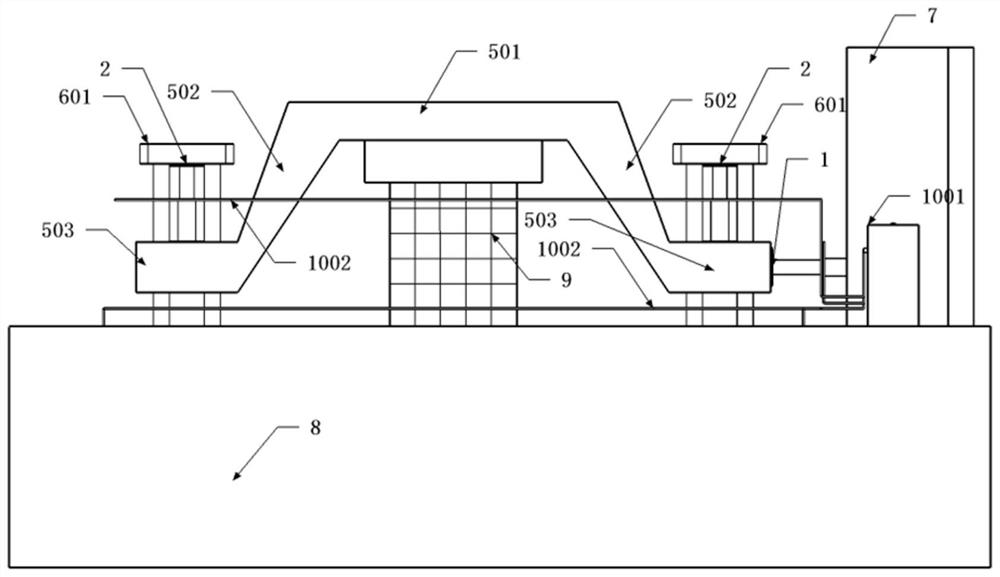

[0035] Such as figure 1 , figure 2 , image 3 A single-side loading large-scale compression-shear-bending composite loading test device is shown, which is used for static reciprocating tests of large structural members under different load combinations. The device includes a sunken floor 8 and a reaction wall 7 arranged on one side of the sunken floor 8 . Such as Figure 4 As shown, the sunken floor 8 is provided with a test piece placement pit 804 for placing the test piece 9, and both sides of the test piece placement pit 804 are provided with horizontal guide rail actuating mechanisms, and each horizontal guide rail actuates The mechanism is equipped with a vertical actuating mechanism, and a loading frame 5 adapted to the top of the test piece 9 is provided between the two vertical actuating mechanisms, and the side of the reaction wall 7 is provided with a loading frame 5 adapted to horizontal actuator.

[0036] Such as Figure 5 As shown, a console 1001 is provide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap