Intelligent design method of industrial product model

A design method and technology for industrial products, applied in geometric CAD, configuration CAD, etc., can solve problems such as mismatching assembly relationships, product manufacturing defects, and size non-compliance, so as to improve R&D efficiency, improve customer response efficiency, and avoid product Effects of Manufacturing Defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

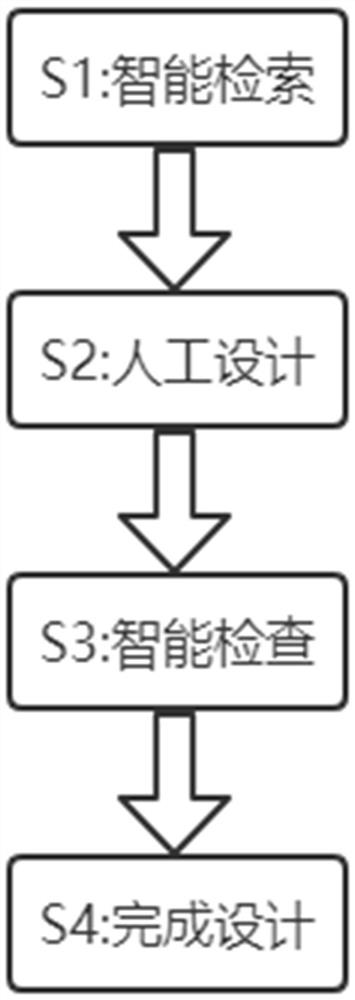

[0076] Please refer to figure 1 , the invention provides a method for intelligent design of industrial product models, the specific steps of the design method are as follows:

[0077] S1: Intelligent search;

[0078] Using the component model attributes of the product 3D model as the search term, search in the component model database, retrieve the component models that meet the retrieval conditions, and obtain similar component models;

[0079] If the component model that meets the retrieval conditions is retrieved, save the component model as a separate file;

[0080] If no part model that meets the retrieval conditions is retrieved, it means that no similar part model has been retrieved; the part model designer shall design the part model, and put the designed mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com