Smashing and planting integrated system for straws in soil

A straw crushing and soil technology, which is applied to agricultural machinery and tools, agriculture, shovels, etc., can solve the problems of inability to carry out deep burial, straw planters ditch and hang grass, and interfere with seed growth, so as to improve picking and processing efficiency, Guarantee the effect of piercing and picking up, and improve the efficiency of collecting and picking up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

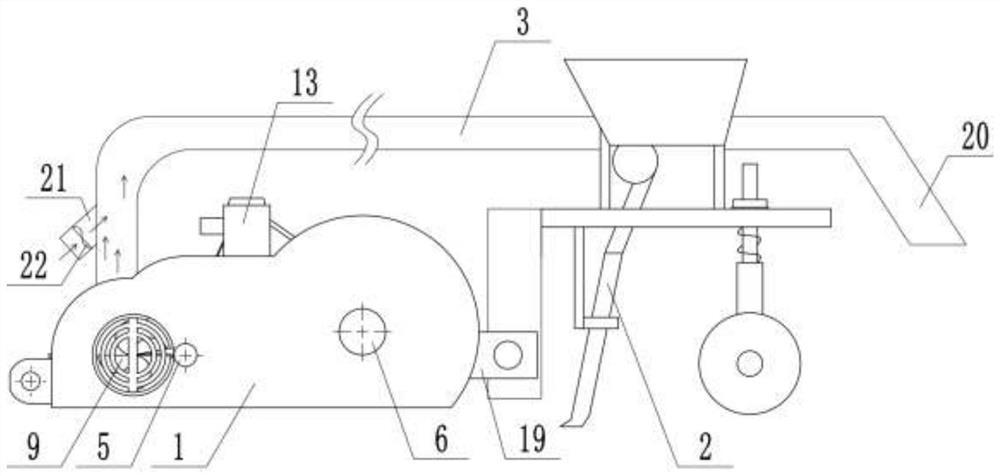

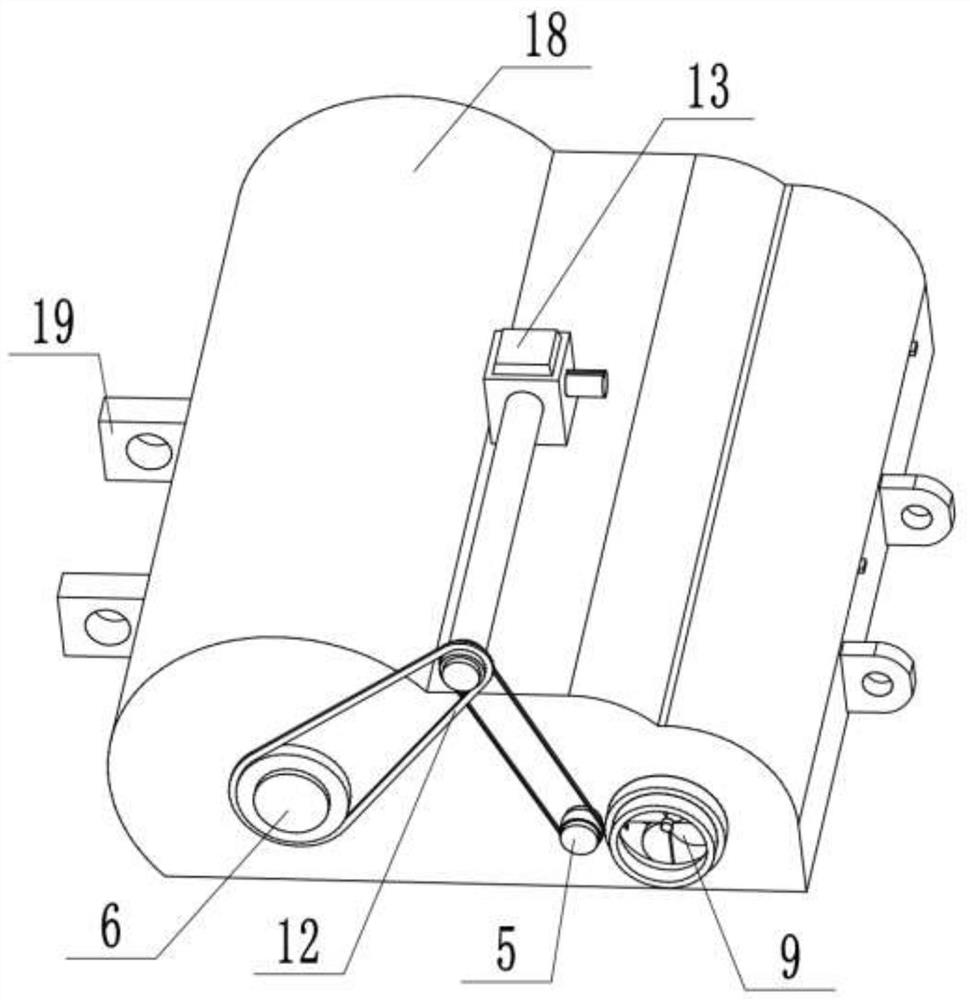

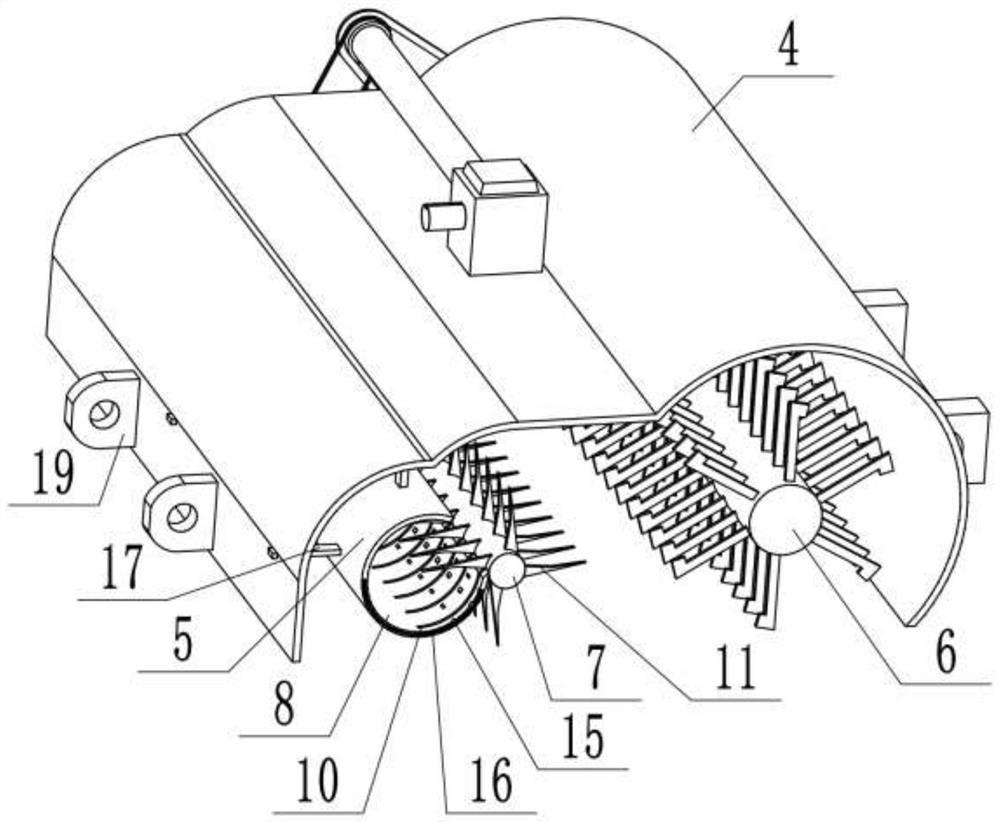

[0033] In a typical embodiment of the present disclosure, such as Figure 1-Figure 6 As shown, an integrated system for crushing and planting straw in soil is given.

[0034] It mainly includes a crushing device 1, a seeding device 2 and a guiding mechanism 3, wherein the crushing device and the guiding mechanism are the core components in this embodiment, and carry out straw picking, collecting, crushing and secondary laying of straw on the land after the straw is returned to the field the process of. The sowing device is located between the crushing device and the output end of the guiding mechanism, and sows the shallow land after picking up the straw, and the sown area is covered by the straw output by the guiding mechanism.

[0035] When the sowing device is sowing, the straw in the shallow land in front has been picked up and removed, thus solving the problem that the straw is not completely crushed in the shallow land in the straw returning area, and the remaining stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com