Carrier for picking mature corn

A kind of truck and mature technology, applied in the field of trucks, can solve the problems of insufficient stability, unsatisfactory use, single structure, etc., and achieve the effect of improving picking and handling efficiency, improving overall service life and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

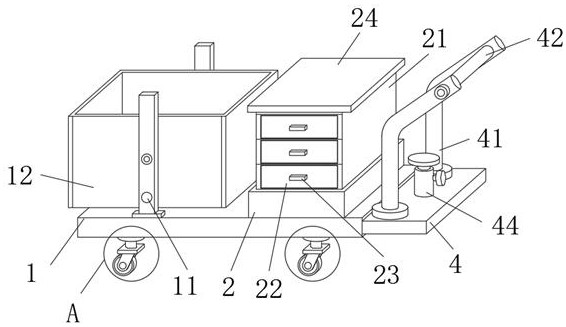

Embodiment 1

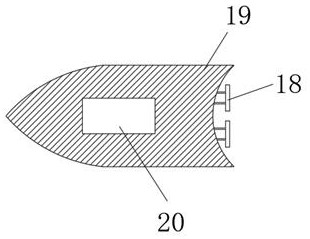

[0028] Embodiment 1: when this kind of corn is harvested when it is mature, the transport vehicle can be used to fix its frame 12 by inserting rods, so as to avoid the phenomenon that the frame 12 shakes when the corn is placed, and the positioning column 18 utilize nuts to install it on one side of the car frame 12 so that the road breaking board 19 is in front of the truck, and then the corn picking personnel can hold the handle 42 by hand and apply force to it to use the universal Wheel 54 moves its carrier to the corn picking ground, and the corn it picks can be placed in the car frame 12, and when its carrier needs to be moved forward, the road-breaking plate 19 in the front of the carrier can be increased to make In the process of moving forward, the truck opens up a path between the corn stalks to prevent the corn stalks from scratching the picking personnel, and when picking, it can be extended by the movement of the piston cylinder 40 to make it Base 37 contacts with ...

Embodiment 2

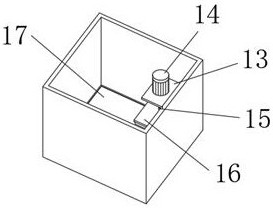

[0029] Embodiment 2: and its electric mechanism 2 can increase the temperature of its internal electronic unit under long-term use, at this moment it can be started by the peripheral switch of drive block 31, and its drive block 31 can drive the fan on the top. The blade 32 rotates, and the power mechanism 2 can be dissipated through the through hole 43 at the top of the support mechanism 3, which effectively reduces the heat generated by the electric operation of the power mechanism 2 itself, and improves the performance of the power mechanism 2 in this way. Service life, when the picking is completed, the corn can be released from the picking ground to unload the corn, the picker can start the servo motor 14 through the start button, and the servo motor 14 can drive the connecting seat 16 to the lifting plate through the rotation of the screw mandrel 15 17 is carried out so that it is away from the opening at one end of the lifting plate 17 of the servo motor 14, and the corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com