Automatic filling equipment for sandbag

An automatic filling and equipment technology, which is applied in the field of sandbags, can solve the problems of uneven packing compaction and affect the training effect, and achieve the effect of consistent packing compaction, reducing labor intensity and speeding up filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

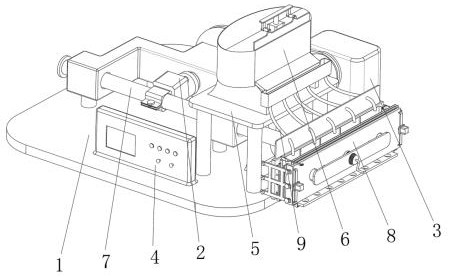

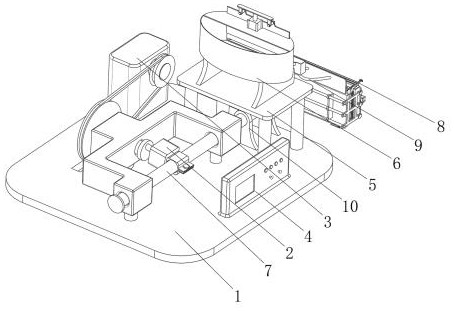

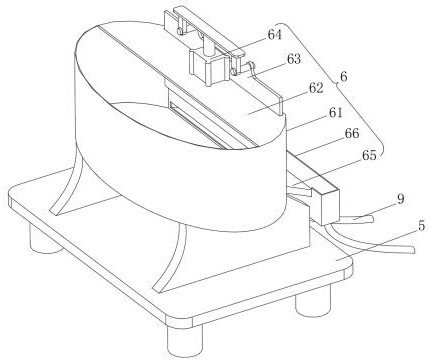

[0036] see Figure 1-9, the present invention provides a technical solution: an automatic filling device for sandbags, including a power supply base 1, the top of the power supply base 1 is fixedly connected with a swing mechanism 2 through a support rod, which plays a role in mixing and shaking the iron sand in the flowing PU leggings-bearing sandbag. The role is to speed up the filling of iron sand and make the content of iron sand between each sewing filling strip the same. The inside of the swing mechanism 2 is connected to the driving device 3 through the transmission of the belt group. The bottom of the driving device 3 is fixedly connected to the top of the power supply base 1, and the power supply base 1 The top is fixedly connected with the control cabinet 4, the control cabinet 4 is located on the side of the swing mechanism 2, the top of the swing mechanism 2 is provided with a support seat 5, and the top of the support seat 5 is fixedly connected with the feeding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com