Code spraying equipment for medical composite hard sheet packaging

A composite hard chip and inkjet technology, which is applied in packaging, printing, typewriters, etc., can solve the problems of inconvenient adjustment, inconvenient adjustment of the position of inkjet equipment, cumbersome operation steps, etc., and achieve the effect of easy replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

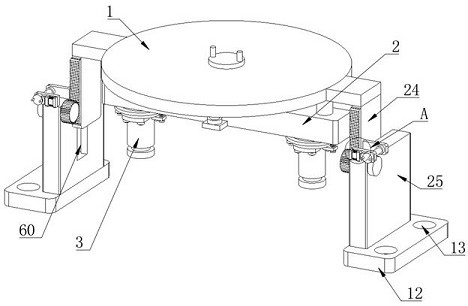

[0034] Embodiment one, by Figure 1 to Figure 8 Given, the present invention includes a supporting and fixed top plate 1, a rotary coding control adjustment seat 2 and two coding equipment bodies 3, the rotary coding control and adjustment seat 2 is arranged under the support and fixed top plate 1, and the coding equipment The main body 3 is arranged below the rotary coding control adjustment seat 2, and the bottom of the supporting and fixed top plate 1 is provided with an annular groove 4, and the top of the rotary coding control adjustment seat 2 is provided with a support ring 5, and the bottom of the support ring 5 is in contact with the rotation The top of the code spraying control adjustment seat 2 is connected by two first connecting columns 7, and the bottom of the rotary code spraying control adjustment seat 2 is provided with a first chute 6, and the first chute 6 is provided with a two-way adjusting screw rod 8, and the two-way Both ends of the adjusting screw rod ...

Embodiment 2

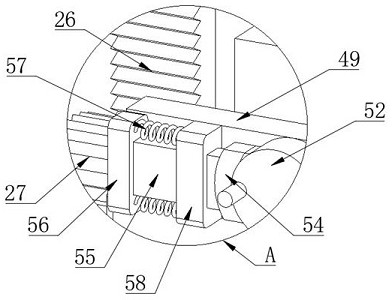

[0038] Embodiment two, on the basis of embodiment one, by figure 2 , Figure 5 , Image 6 with Figure 8Provided, the rotation angle adjustment mechanism includes a rotation chamber 30 opened in the rotation angle adjustment disk 11, a second fixed disk 31 is arranged in the rotation chamber 30, and the top of the second fixed disk 31 is fixedly connected with a connection. Shaft 32, the top of the connecting shaft 32 runs through the top inner wall of the rotating chamber 30, and the top of the connecting shaft 32 is fixedly connected with the bottom of the movable block 10, and the outside of the rotation angle adjusting disc 11 is provided with a fixed ring 33, which is connected to the The rotation angle adjustment disc 11 is fixedly connected, and the bottom of the rotation angle adjustment disc 11 is provided with two pressing movable plates 34, and the bottom of the pressing movable plate 34 is provided with a limit disc 37, and the top of the limit disc 37 is fixedl...

Embodiment 3

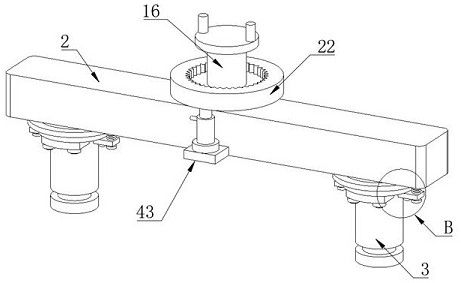

[0040] Embodiment three, on the basis of embodiment one, by figure 2 , Image 6 with Figure 8 Given, two first fixed support plates 40 are fixedly connected to the body 3 of the inkjet coding equipment, and two first threaded posts 41 are arranged below the first fixed support plate 40, and the top ends of the first threaded posts 41 pass through the first fixed support plate 40. A fixed support plate 40, and the top of the first threaded column 41 is fixedly connected with the bottom of the rotation angle adjustment plate 11, the outside of the first threaded column 41 is provided with a nut 42, and the top of the nut 42 is connected to the first fixed support plate 40 The bottom of the locking control member includes a second fixed support plate 43 symmetrically arranged on both sides of the rotary coding control adjustment seat 2, one side of the second fixed support plate 43 and the rotary coding control adjustment seat 2 One side is fixedly connected, the top of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com