Anti-seismic and anti-explosion type nitric acid safety storage tank

An explosion-proof, nitric acid technology, applied in tank trucks, large containers, packaging, etc., can solve problems such as uncontrollable storage volume, safety hazards, safety accidents, etc., and achieve the effect of reducing shaking and safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

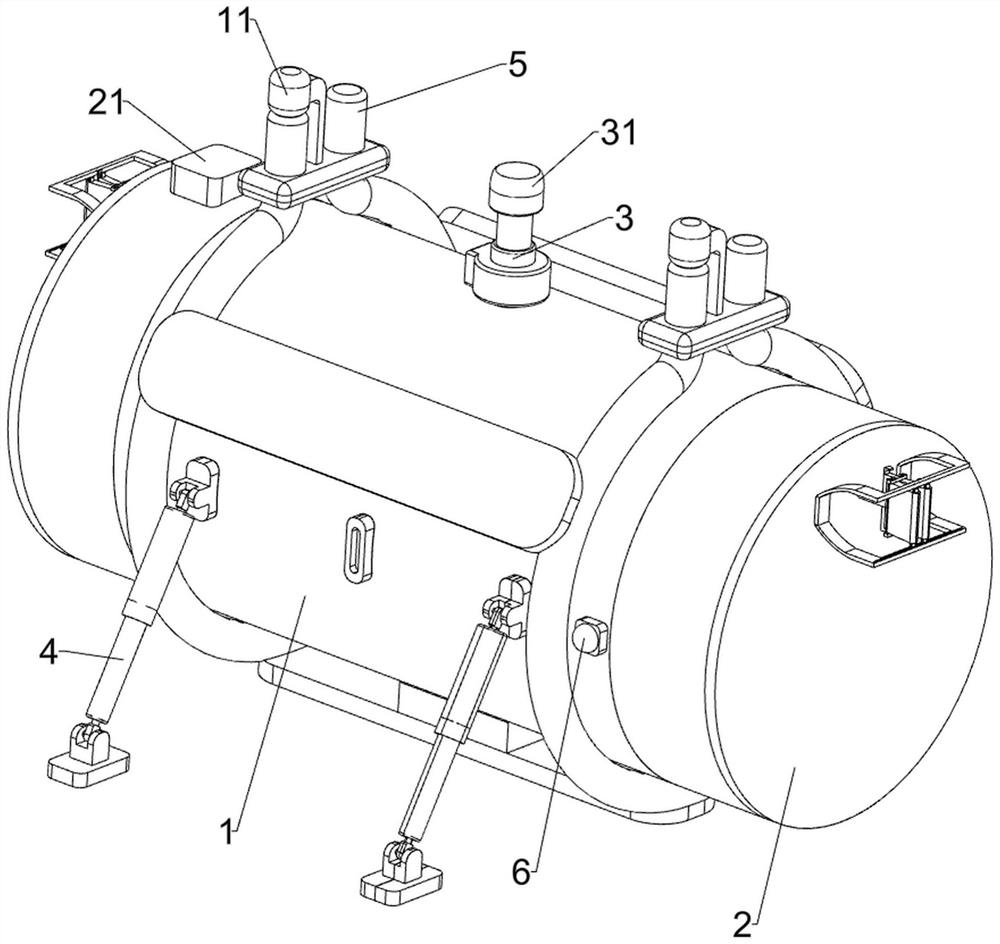

[0035] An anti-shock and explosion-proof nitric acid safety storage tank, such as Figure 1-10 As shown, it includes a storage tank 1, a pressure relief cover 2, a protective cover 31, an anti-seismic mechanism 4, an explosion-proof mechanism 5 and a reserve control mechanism 6, the left and right sides of the storage tank 1 are equipped with a pressure relief cover 2, and the top of the storage tank 1 is installed There is a material injection port 3, a protective cover 31 is provided slidingly on the material injection port 3, an anti-shock mechanism 4 is provided on the front and rear sides of the storage tank 1, an explosion-proof mechanism 5 is provided on the left and right sides of the storage tank 1, and the storage tank 1 is connected to a storage tank at the bottom. Control mechanism6.

[0036] When people need to use this safety storage tank, first press the main power switch, the safety storage tank is powered on, then by opening the protective cover 31 concentrate...

Embodiment 2

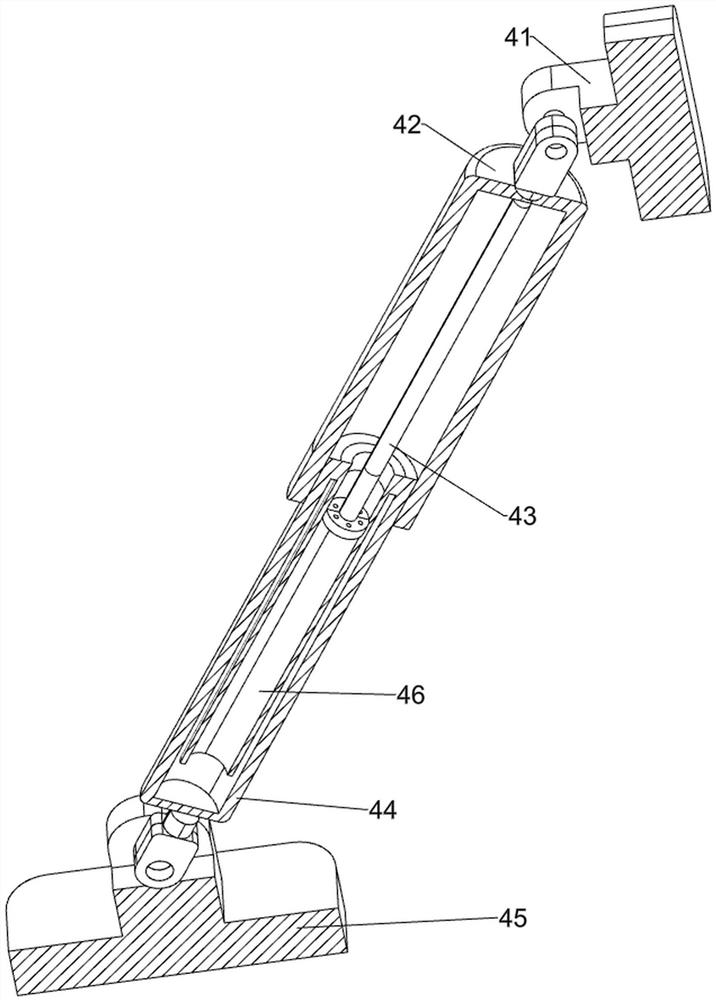

[0038] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Figure 9As shown, the anti-seismic mechanism 4 includes a first fixed block 41, an upper casing 42, a piston 43, a lower casing 44, a second fixed block 45, and an oil storage pipe 46. A fixed block 41, the first fixed block 41 is equipped with an upper sleeve 42 for rotation, the upper side of the upper sleeve 42 is provided with a piston 43, the lower part of the piston 43 has a plurality of small holes, and the upper sleeve 42 is of sliding type. A lower casing 44 is provided, and the lower part of the lower casing 44 is rotatably provided with a second fixed block 45. An oil storage pipe 46 is installed in the lower casing 44, and the oil storage pipe 46 is slidingly connected with the piston 43. The oil storage pipe 46 is connected to the lower casing There are gaps between the 44 inner walls.

[0039] The explosion-proof mechanism 5 includes a first connection an...

Embodiment 3

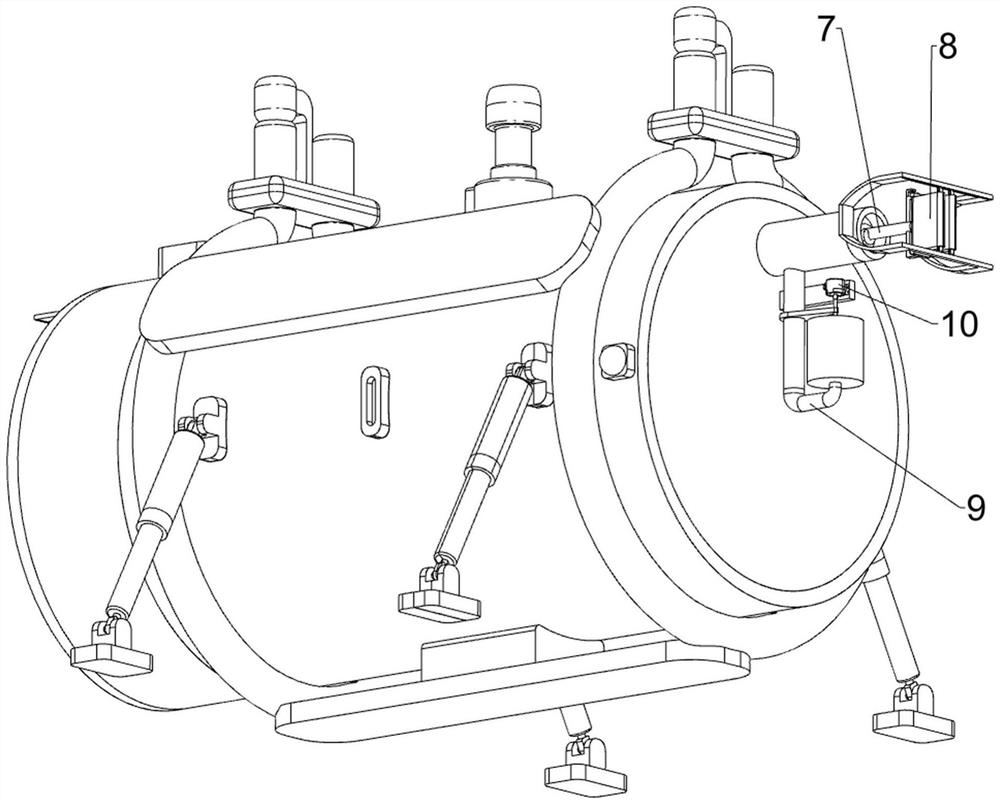

[0044] On the basis of Example 2, such as Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 with Figure 12 Shown, also include conduction mechanism 9, conduction mechanism 9 includes air release pipe 91, air transmission pipe 92, reaction container 93 and diffuse gas cover 94, storage tank 1 left and right sides upper parts are all connected with air release pipe 91, and air release pipe 91 all Located in the upper part of the pressure relief cover 2, the bottom of the air release pipe 91 is connected with an air pipe 92, the top of the air pipe 92 is connected with a reaction vessel 93, and the bottom of the reaction vessel 93 is connected with an air diffuser cover 94.

[0045] Also include pressure relief mechanism 7, pressure relief mechanism 7 includes sealing ball 71, strong spring 72 and first transmission rod 73, all sliding type is provided with first transmission rod 73 in the vent pipe 91, first transmission rod 73 insides are all A seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com