Fiber composite material forming device and method capable of achieving feeding and discharging conveniently

A fiber and fixed shell technology, which is applied in the field of fiber composite material processing, can solve the problems of inconvenient position replacement, inconvenient adjustment operation, inconvenient adjustment, etc., so as to improve efficiency and realize the effect of adjusting the movement of the support plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

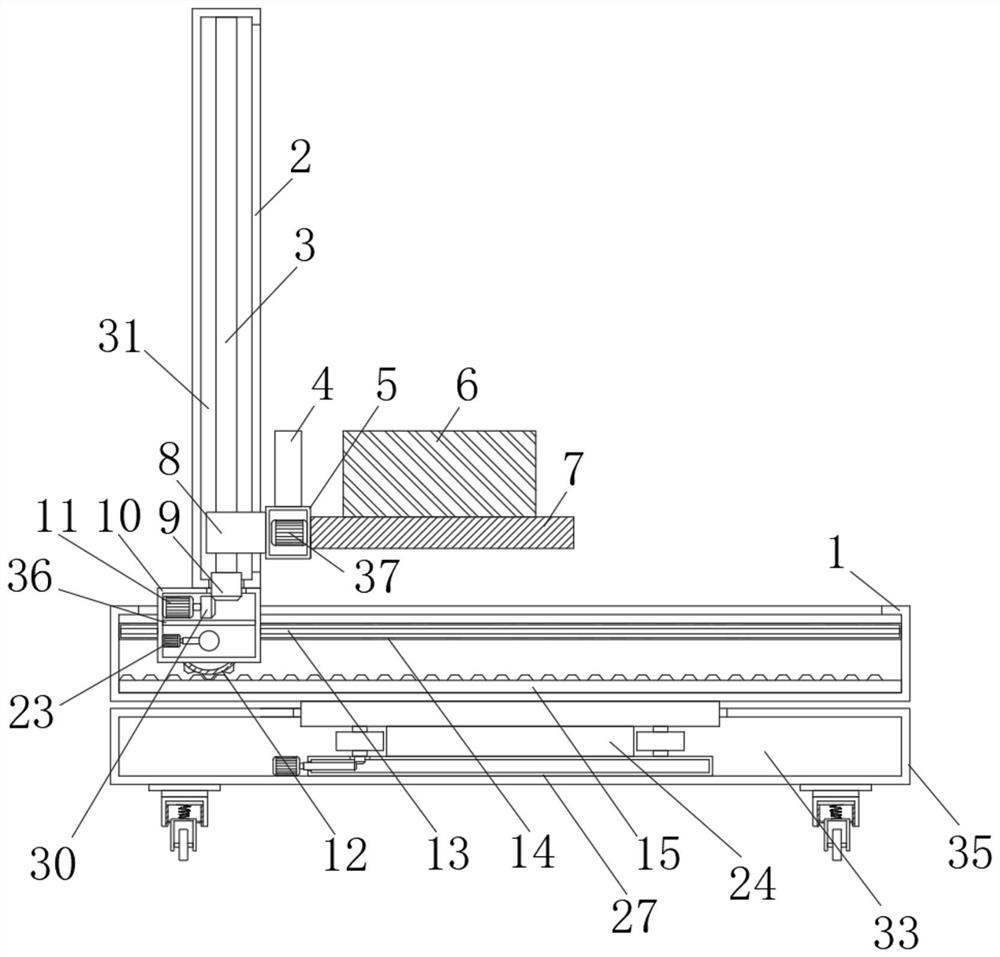

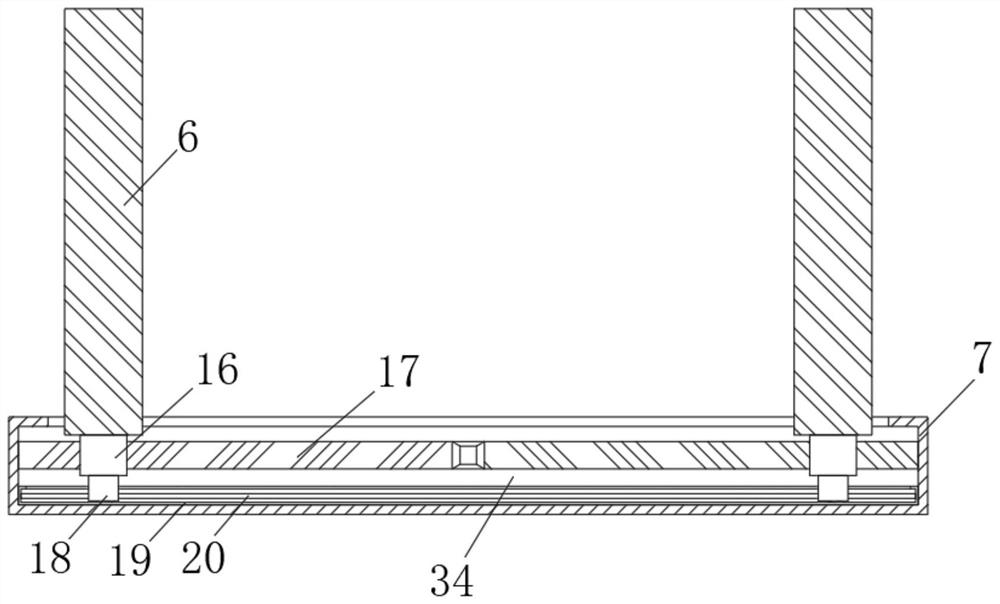

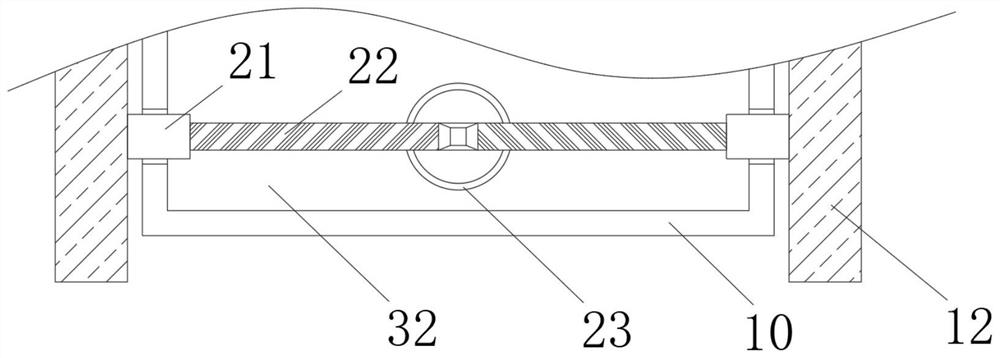

[0027] Example: such as Figure 1-5 As shown, the present invention is a device for forming fiber composite materials that is convenient for loading and unloading, including: a fixed shell 1, a rotating base 35 is provided at the bottom of the fixed shell 1, a rotating mechanism 33 is provided inside the rotating base 35, and the fixed shell 1 The interior is provided with movable box 10, and the inside of movable box 10 is fixedly connected with dividing plate 36, and the bottom of dividing plate 36 is provided with rotating mechanism 32, and the top of movable box 10 runs through fixed shell 1 and is fixedly connected with fixed column 2, fixed column 2 There is a lifting mechanism 31 inside, a fixed box 5 is arranged on one side of the fixed column 2, the top of the fixed box 5 is fixedly connected with a buffer plate 4, and the end of the fixed box 5 away from the fixed column 2 is fixedly connected with a support plate 7, and the support plate The inside of 7 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com