Glass base material manufacturing device

A manufacturing device and glass technology, which is applied in the field of manufacturing devices for glass base materials, can solve problems such as large variation in outer diameter, and achieve the effect of suppressing variation in outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

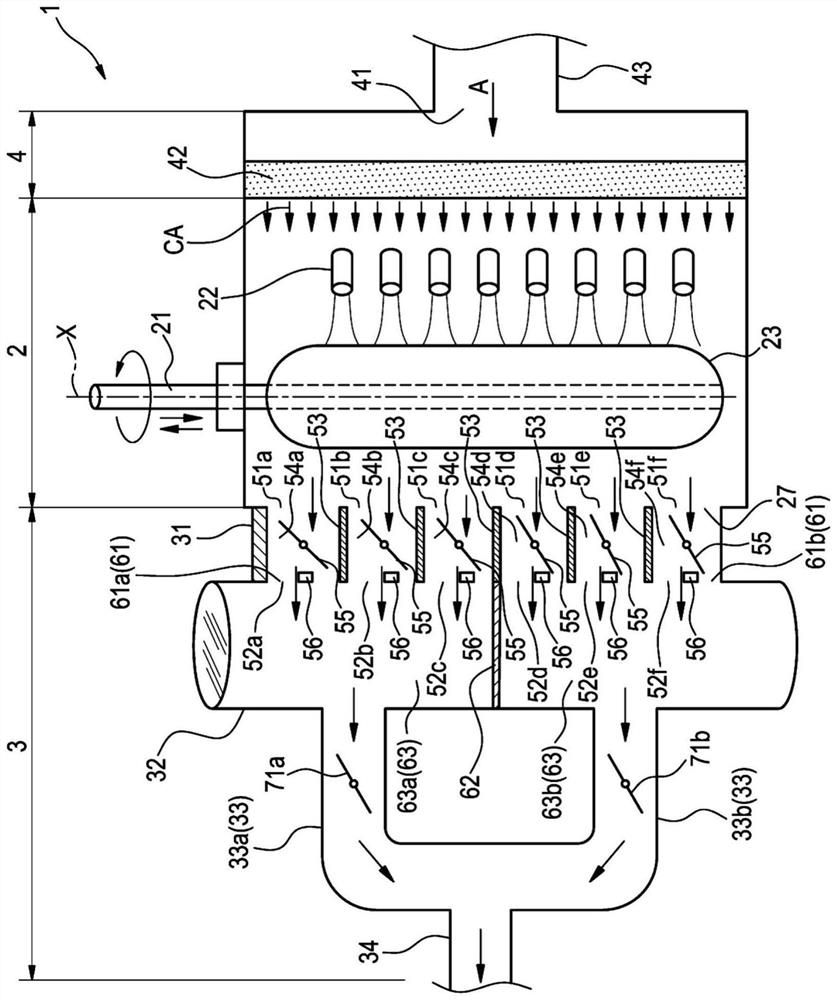

[0024] (Description of embodiment of the present invention)

[0025] First, embodiments of the present invention will be cited and described.

[0026] An apparatus for manufacturing a glass base material according to an aspect of the present invention,

[0027] (1) Glass particles are deposited around an initial rod that rotates around a rotating shaft extending in the vertical direction in the interior of the reaction vessel to produce a glass base material,

[0028] The manufacturing device of the glass base material has:

[0029] a plurality of glass synthesizing burners arranged vertically inside the reaction vessel to generate the glass particles; and

[0030] an exhaust unit, which exhausts the waste gas generated inside the reaction container to a detoxification device provided outside the reaction container,

[0031] The exhaust section includes:

[0032] The main exhaust pipe, the first end of which is connected to the detoxification device;

[0033] a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com