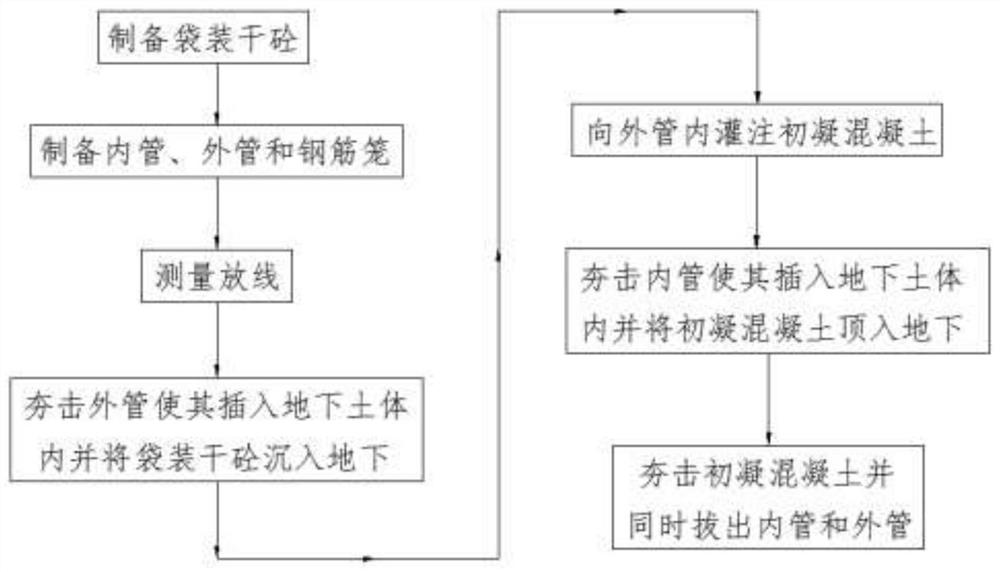

Construction process of rammed and expanded pile

A construction technique, a technique of ramming and expanding piles, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of increased pile end resistance, low single pile bearing capacity, and low efficiency, and achieves increased pile end loads The effect of increasing the force and increasing the cross-sectional area of the pile end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

[0023] Such as figure 1 As shown, the present invention provides a kind of tamping pile construction technique, comprises the following steps:

[0024] Step 1: Provide several packaging bags, then fill each packaging bag with an appropriate amount of cement, and then seal the packaging bags to obtain several bags of dry concrete; in the preparation process of bagged dry concrete in step 1, each packaging bag The mass of cement filled inside shall not be less than 30kg.

[0025] Step 2: preparing an inner pipe, an outer pipe and a reinforcement cage, the inner diameter of the outer pipe is larger than the outer diameter of the inner pipe, and the inner diameter of the inner pipe is larger than the outer diameter of the reinforcement cage;

[0026] Step 3: Measurement and setting out: carry out measurement and setting out according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com