Ground engaging tool control system and method

A ground engaging tool and control system technology, applied in the field of ground engaging tool control systems, can solve problems such as uneven distribution of materials, inability to guide materials at the same time, and unfavorable cuts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

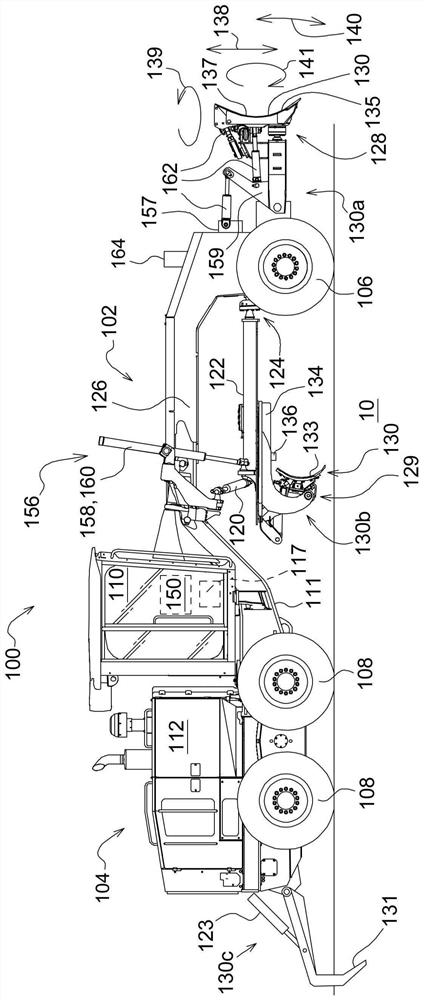

[0020] refer to Figure 1A to Figure 2 , shows work vehicle 100 including ground engaging tool control system 150 . Although in Figure 1A In the illustration, work vehicle 100 is shown as including a motor grader, but it should be noted that in other embodiments, the type of work vehicle 100 may vary depending on the application and / or specification requirements. For example, in some embodiments, work vehicle 100 may include a tracked or unmanned vehicle, and may also include: a road grader, a dozer, a bulldozer, and a front loader. loader), and the embodiments discussed herein are for exemplary purposes only to help understand the present disclosure.

[0021] Such as Figure 1A As shown, the work vehicle 100 may include a front frame 102 supported on a pair of front wheels 106 and a rear frame 104 supported on a set of rear wheels 108 connected in series left and right. In various implementations, the design of the front frame 102 and / or the rear frame 104 may vary based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com