Sectional piston rod connecting structure of drilling pump

A connection structure, piston rod technology, applied in the direction of pump components, variable displacement pump components, components of pumping devices for elastic fluids, etc., can solve problems such as difficult disassembly and large torque values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] The embodiments of the present invention are not limited to the following examples, and various changes made without departing from the gist of the present invention fall within the protection scope of the present invention.

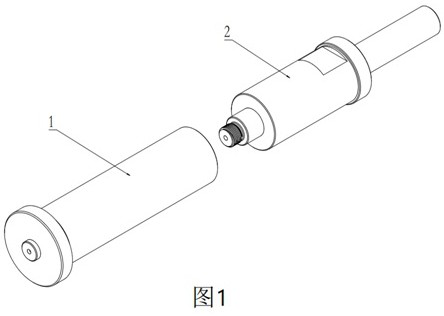

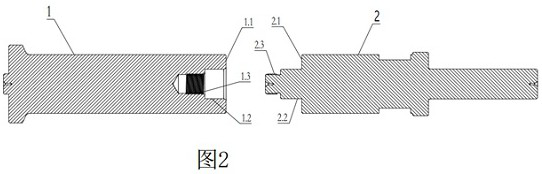

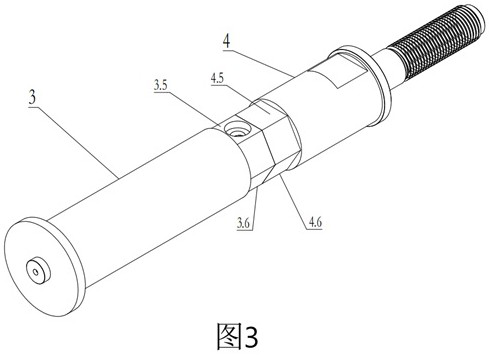

[0036] see Figure 1 to Figure 5 , a segmented piston rod connection structure of a drilling pump in this embodiment, including a rear piston rod semi-finished product 1, a front piston rod semi-finished product 2, a rear piston rod finished product 3, a front piston rod finished product 4, a 16mm taper pin 5, and a spring washer 6. Nut 7, end face 1.1, inner hole 1.2, M27×2 internal thread 1.3, end face 2.1, outer circle 2.2, M27×2 outer thread 2.3, end face 3.1, outer circle 3.2, tapered hole surface 3.3, counterbore surface 3.4, Upper plane 3.5, lower plane 3.6, counterbore inner circle 3.7, end face 4.1, outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com