Metal composite plate surface milling device

A technology of metal composite board and milling device, which is applied in the direction of positioning device, metal processing equipment, metal processing machinery parts, etc., can solve the problems of fixture and tool collision damage, cumbersome installation, inconvenient operation, etc., to ensure flatness, adsorption Strong and convenient milling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific embodiments.

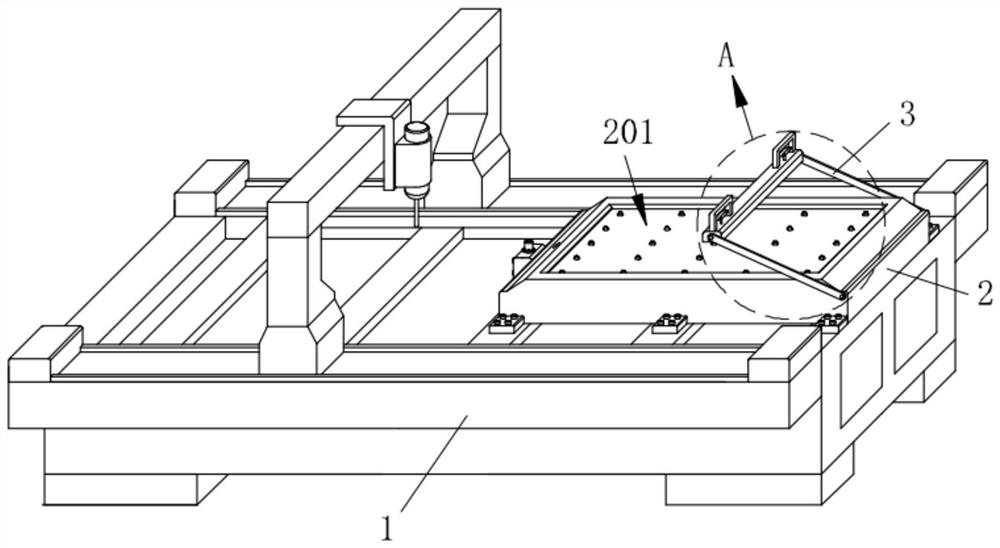

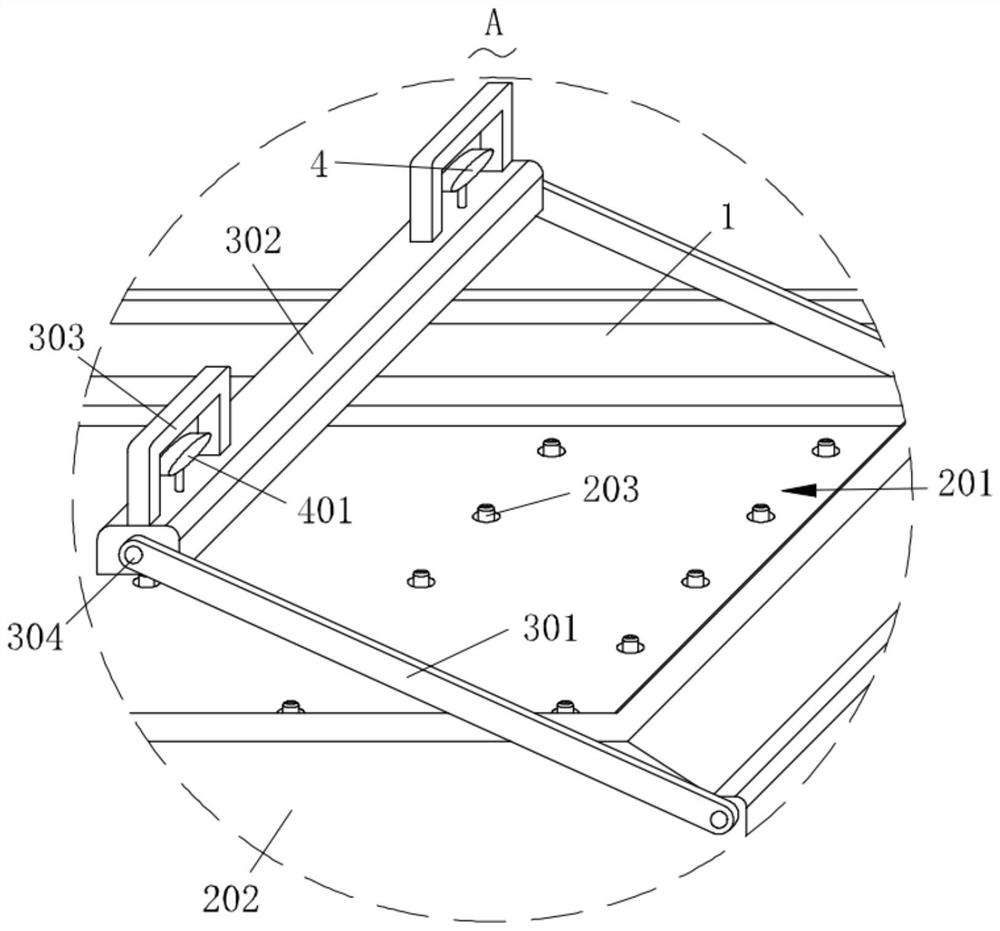

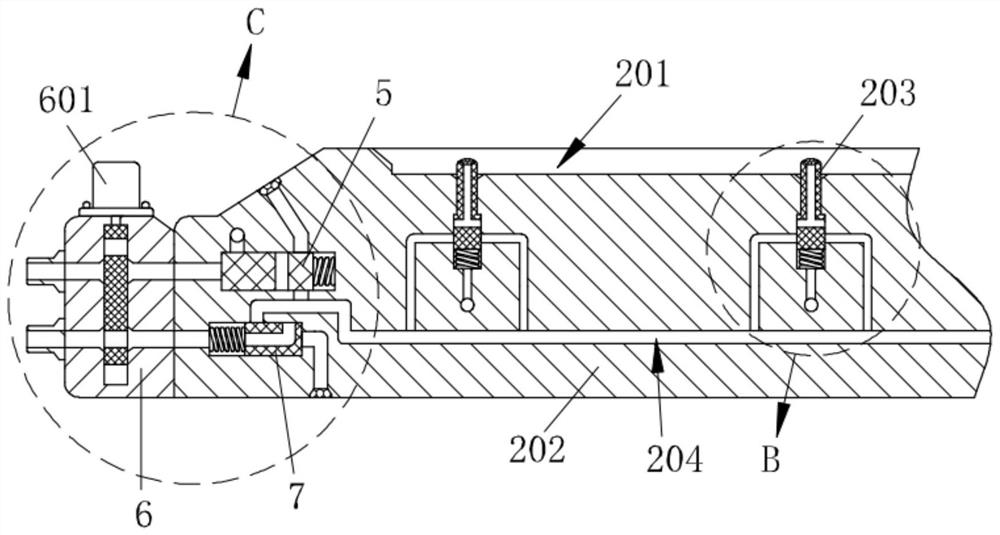

[0030] like Figure 1 - Figure 6 , The metal surface of the composite sheet of the milling device of the present invention comprises a machine body 1, said placing means is mounted on the machine body 12, the placement means 2 is mounted on the guard means 7, the placement means 2 the connecting mechanism 5 are inconsistent, the control means is mounted on the placement means 26, the cutting mechanism is connected is placed on the mechanism 23, the lower mounting means 4 with a return feed mechanism 3.

[0031] Specifically, the placement means 202 includes a base 2, the machine body 1 is detachably connected to the base 202, the base 202 is provided with grooves 201 is placed, the base 202 is provided with a plurality of inner slide equally space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com