A device for removing ic chip silk screen for built-in mobile phone accessories

A technology for mobile phone accessories and screen printing, which is applied to grinding drive devices, grinding machine parts, grinding automatic control devices, etc., can solve problems such as large operation volume and hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

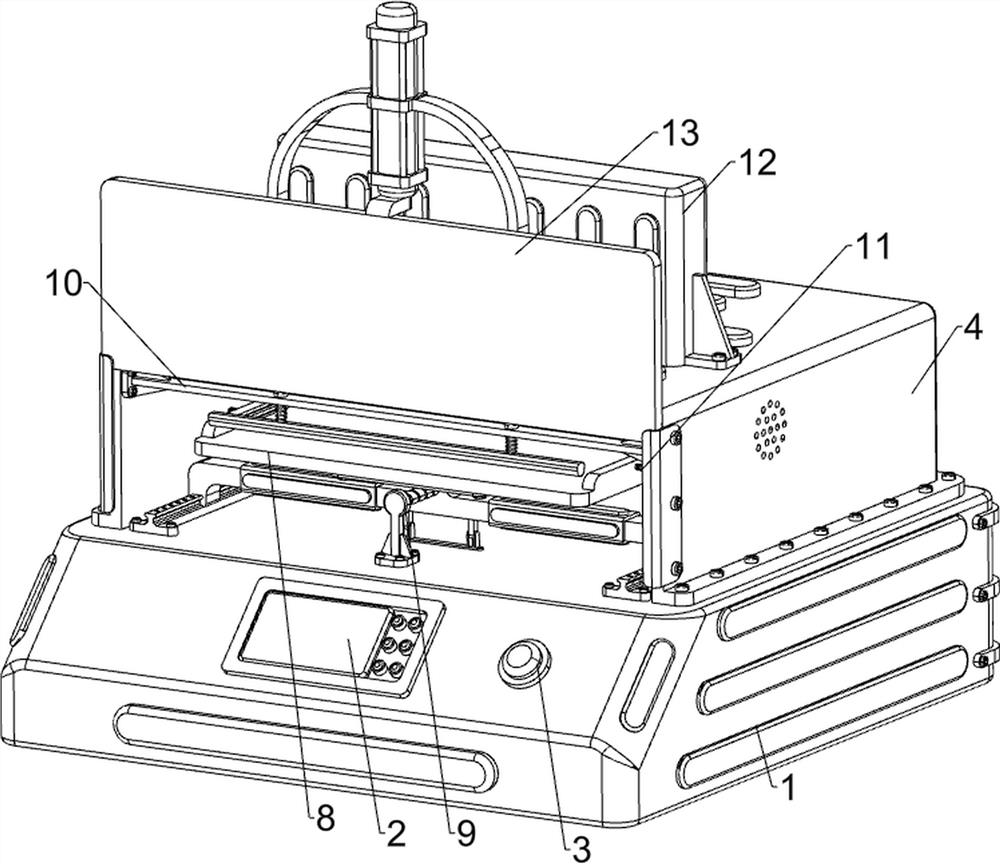

[0037] An IC chip silk screen removing device for built-in mobile phone accessories, such as Figure 1 to Figure 6 As shown, it includes a base 1, a start switch 3, a protective cover 4, a mounting seat 5, a first drive motor 6, a grinding wheel 7, a placement assembly 8 and an automatic feeding mechanism 9, and a start switch 3 is provided on the front right side of the base 1, A protective cover 4 is connected to the top of the base 1, a mounting seat 5 is provided on the right side of the inner wall of the protective cover 4, a first drive motor 6 is provided on the left side of the mounting seat 5, and a grinding wheel 7 is rotatably provided on the left side of the top inner wall of the protective cover 4 for grinding. The right side of the wheel 7 is connected with the first driving motor 6 , and a placing component 8 is arranged on the top of the base 1 , and an automatic feeding mechanism 9 is arranged on the placing component 8 .

[0038] The placement assembly 8 incl...

Embodiment 2

[0042] On the basis of Example 1, as figure 1 , figure 2 , Figure 7 , Figure 8 and Figure 9 As shown, it also includes an anti-stacking mechanism 10, and the anti-stacking mechanism 10 includes a mounting bracket 101, an anti-stacking plate 102 and a first limit spring 103, and the front inner wall of the protective cover 4 is connected between the left and right sides of the installation bracket 101. In the bracket 101 , the bottom of the mounting bracket 101 is slidably provided with an anti-stacking plate 102 , and a first limit spring 103 is symmetrically connected between the anti-stacking plate 102 and the bottom of the mounting bracket 101 .

[0043] It also includes an epicyclic disc clamping mechanism 11. The epicyclic disc clamping mechanism 11 includes a limiting column 111, a second limiting spring 112 and a clamping block 113. The left and right sides of the placing table 84 are provided with limiting columns 111, and the placing platform 84 The left and r...

Embodiment 3

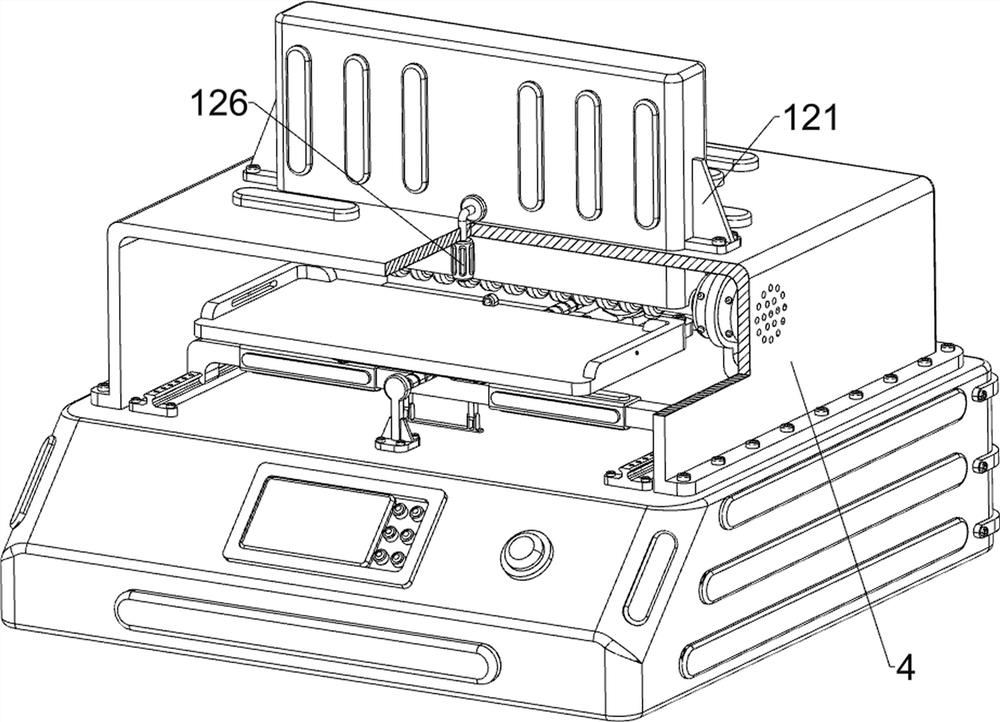

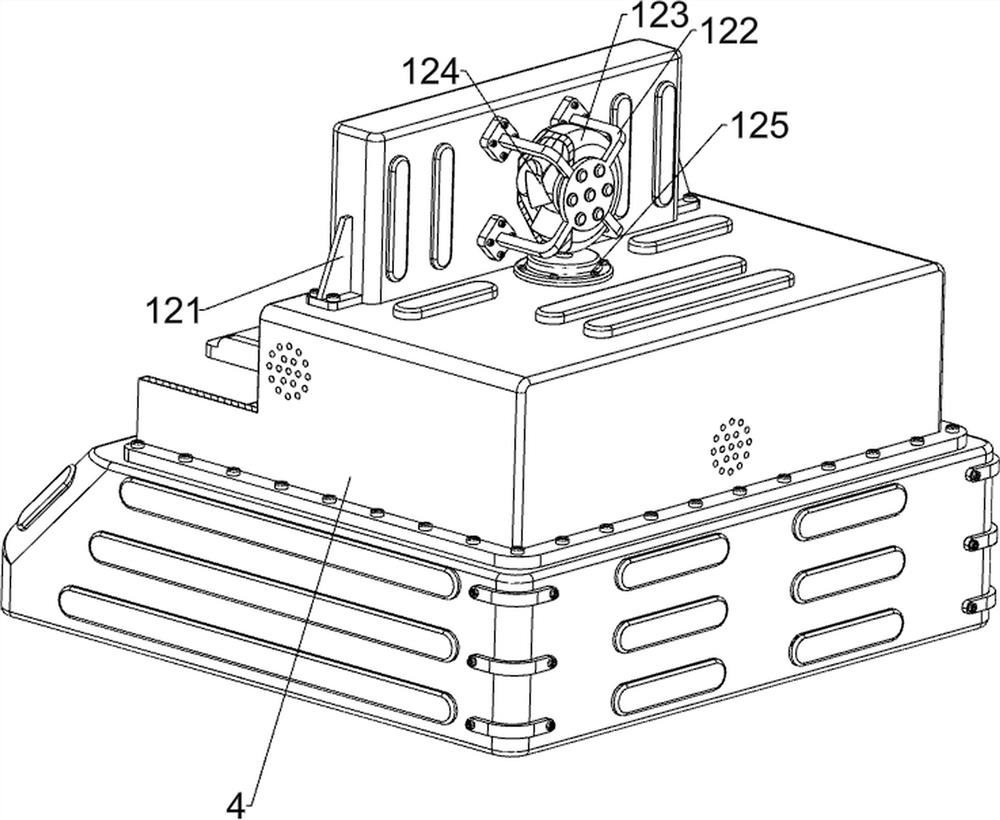

[0046] On the basis of Example 2, as figure 1 , figure 2 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, it also includes a dust suction mechanism 12. The dust suction mechanism 12 includes a mounting groove plate 121, a support frame 122, a mounting cover 123, a fan 124, a dust collecting box 125 and a smoke sensor 126. The top of the protective cover 4 is provided with a mounting groove. Plate 121, four support brackets 122 are arranged at equal distances on the rear side of the installation groove plate 121, and an installation cover 123 is connected between the support brackets 122. The rear side of the inner wall of the installation cover 123 is rotatably provided with a fan 124. The bottom of the installation cover 123 and the protective cover A dust collecting box 125 is connected between the tops of 4, and a smoke sensor 126 is connected to the bottom of the front side of the installation groo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap