Building material recovery device

A technology for recycling devices and building materials, applied to grinding machines, parts of grinding machine tools, grinding/polishing equipment, etc., can solve problems such as infectious diseases and low efficiency, and achieve the effects of enhancing earthquake resistance, improving efficiency, and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

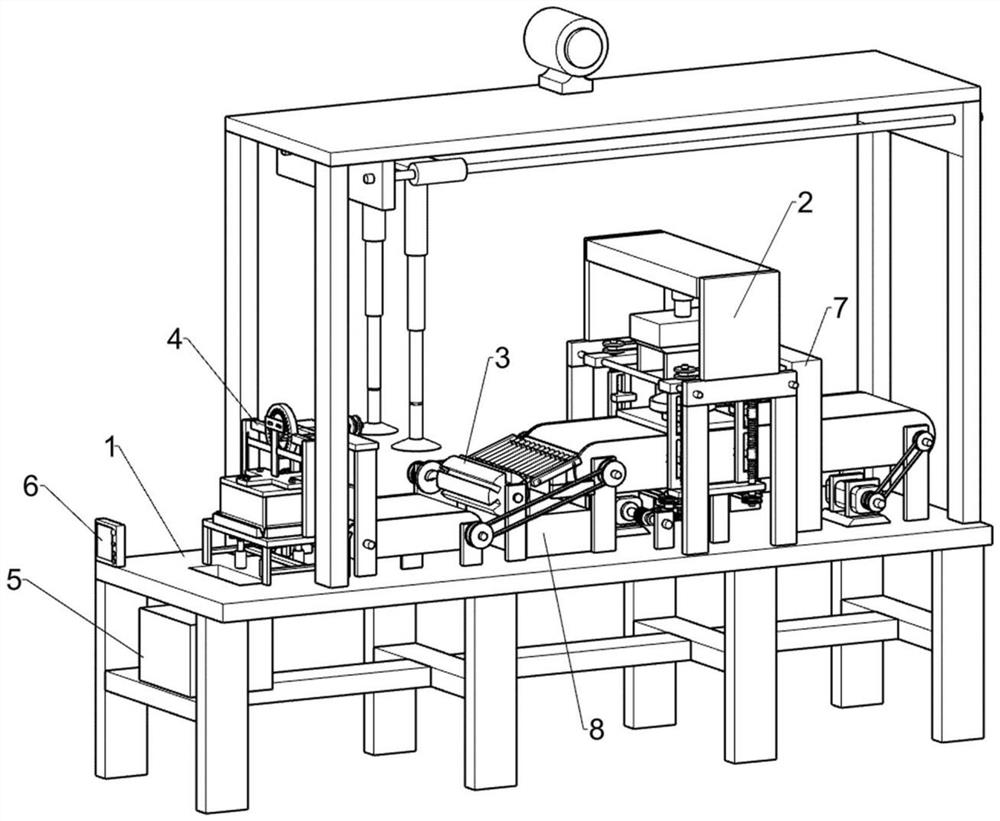

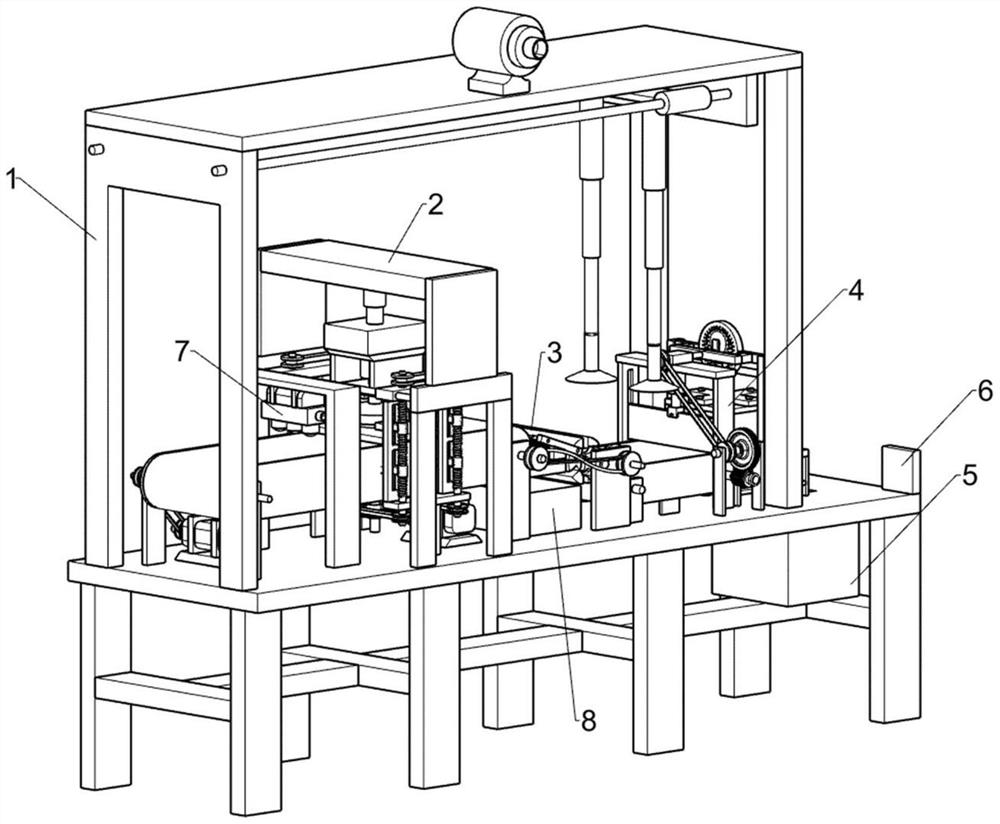

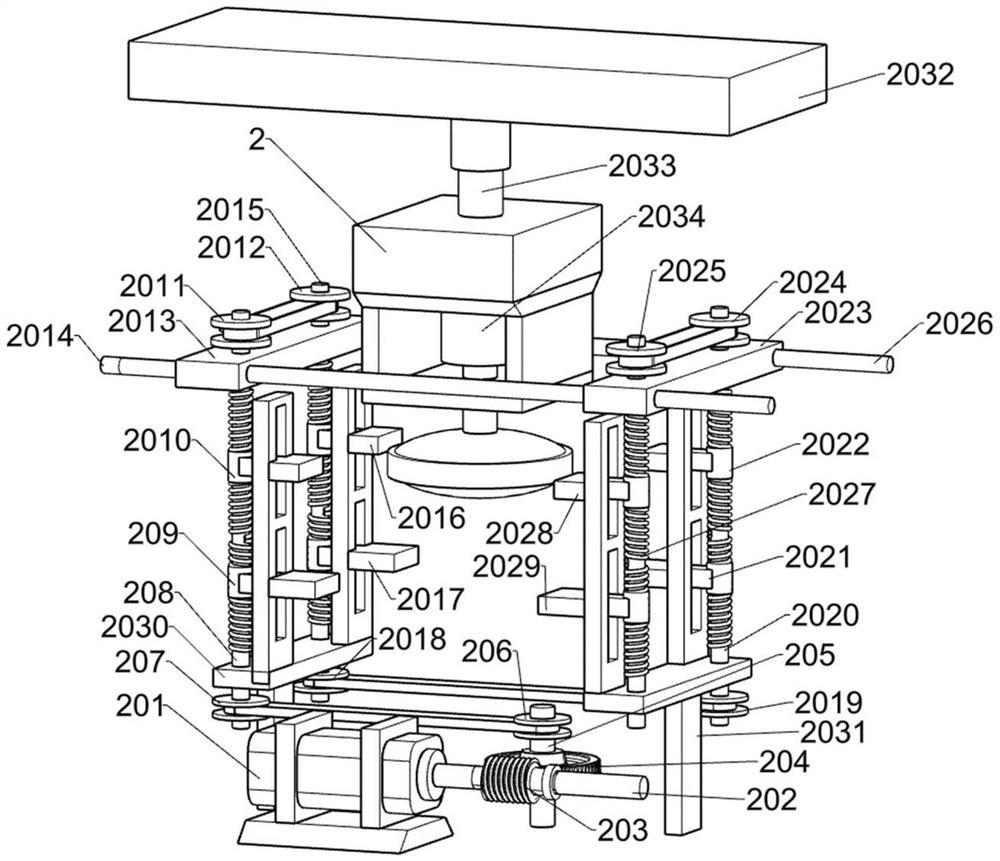

[0028] A construction material recovery device such as Figure 1-8 As shown, it includes a bottom frame 1, a grinding mechanism 2, a turning mechanism 3, a cutting mechanism 4, a first collection box 5, a control panel 6, a sensor 7 and a second collection box 8; the bottom frame 1 is connected to the polishing mechanism 2; The bottom frame 1 is connected with the turning mechanism 3; the bottom frame 1 is connected with the cutting mechanism 4; the bottom frame 1 is connected with the first collection box 5; the bottom frame 1 is connected with the control panel 6; the bottom frame 1 is connected with the sensor 7 The bottom frame 1 is connected with the second collection box 8; the sensor 7 is arranged beside the grinding mechanism 2; the turning mechanism 3 is connected with the cutting mechanism 4; the second collecting box 8 is arranged below the turning mechanism 3; First collection box 5.

[0029] When in use, first place the building material recovery device at the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com