A transfer type chip packaging device

A technology of chip packaging and packaging slots, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems affecting chip quality, heat dissipation stability, and easy existence of voids, etc., to reduce void content and eliminate voids , the effect of increasing the area of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

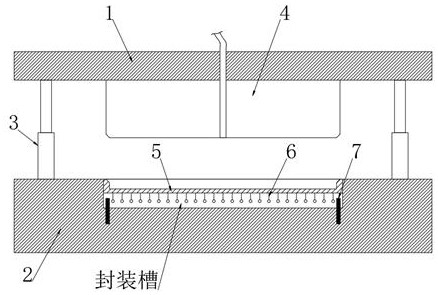

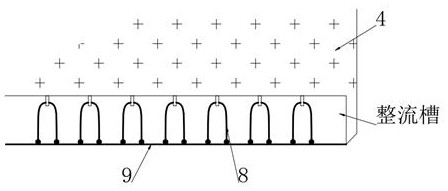

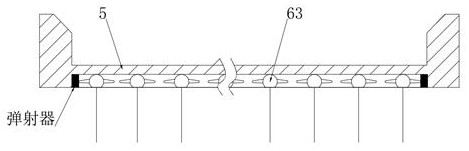

[0043] see figure 1 , a transfer-type chip packaging device, including a fixed template 2, a controller is installed on the fixed template 2, the upper end of the fixed template 2 is connected to a movable template 1 through a plurality of cylinders 3, and a pressure module 4 is fixedly connected to the lower end of the movable template 1. A packaging groove corresponding to the pressing module 4 is excavated at the upper end of the template 2, a glue injection tube is fixed through the movable template 1 and the pressing module 4, and a packaging tray 5 is fixedly connected to the inner wall of the packaging groove. There is a transmission magnetic attraction module, and the lower end of the pressing module 4 and the mouth of the packaging tray 5 are all provided with cut corners, and the cut corners of the two match each other, effectively controlling the distance between the pressing module 4 and the chip, and providing a certain amount for the sealing layer. Space.

[004...

Embodiment 2

[0052] see Figure 10 A plurality of through holes corresponding to the moving magnetic balls 832 are excavated on the reorganized moving piece 9, and the lower moving piece 11 is fixedly connected in the through holes, and the lower moving piece 11 is fixedly connected with the moving magnetic ball 832, and the outer magnetic auxiliary ball 831 The upper end is fixedly connected with the upper moving piece 12, and the edge of the upper moving piece 12 is fixedly connected with the reorganized moving piece 9. The reorganized moving piece 9 is a hard plate structure, and the lower moving piece 11 and the upper moving piece 12 are both elastic structures. 7 When the power is turned on, the lower moving piece 11 is deformed downward, and the upper moving piece 12 is deformed upward, so as to realize the redistribution of the molten epoxy resin. It collides with the hard recombined moving piece 9, thereby generating a certain vibration force. On the one hand, it further promotes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com