Mark printing equipment for relay manufacturing

A technology for printing equipment and relays, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of inability to automatically clamp relays, inability to automatically, etc., and achieve the effect of stirring raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

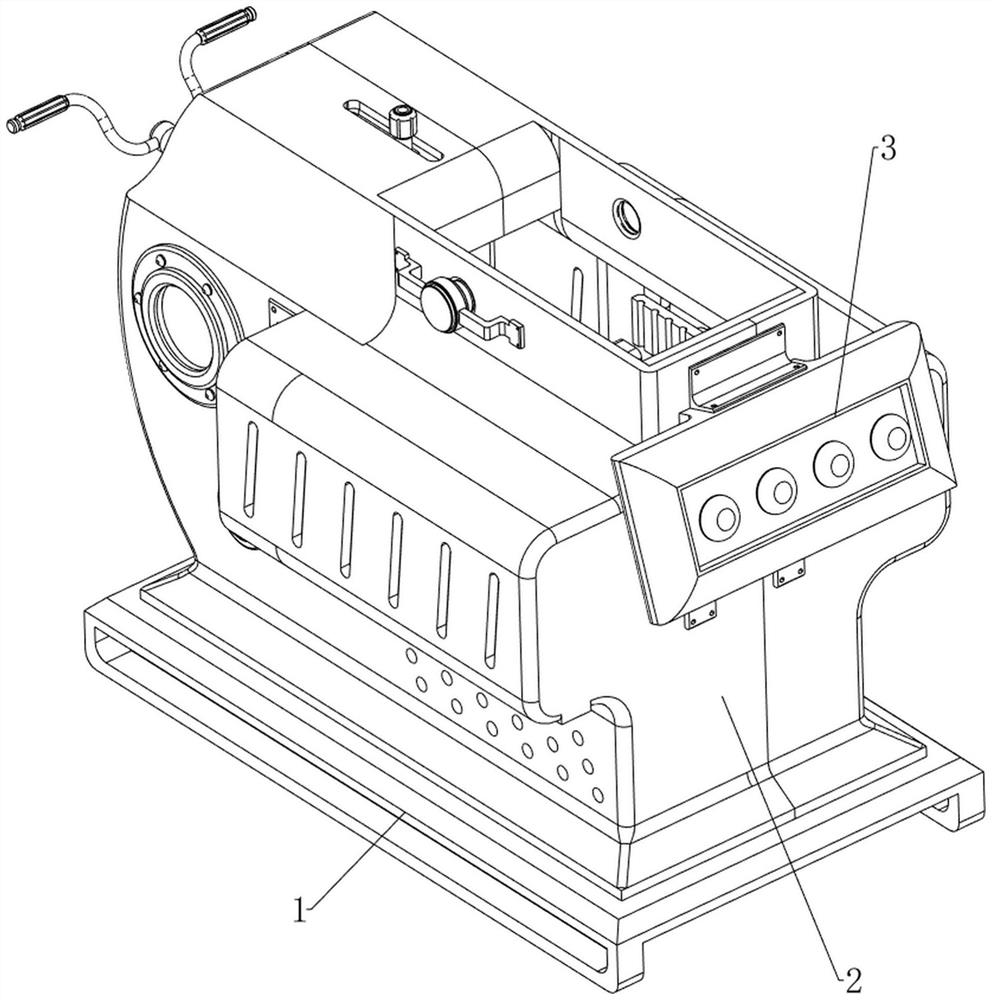

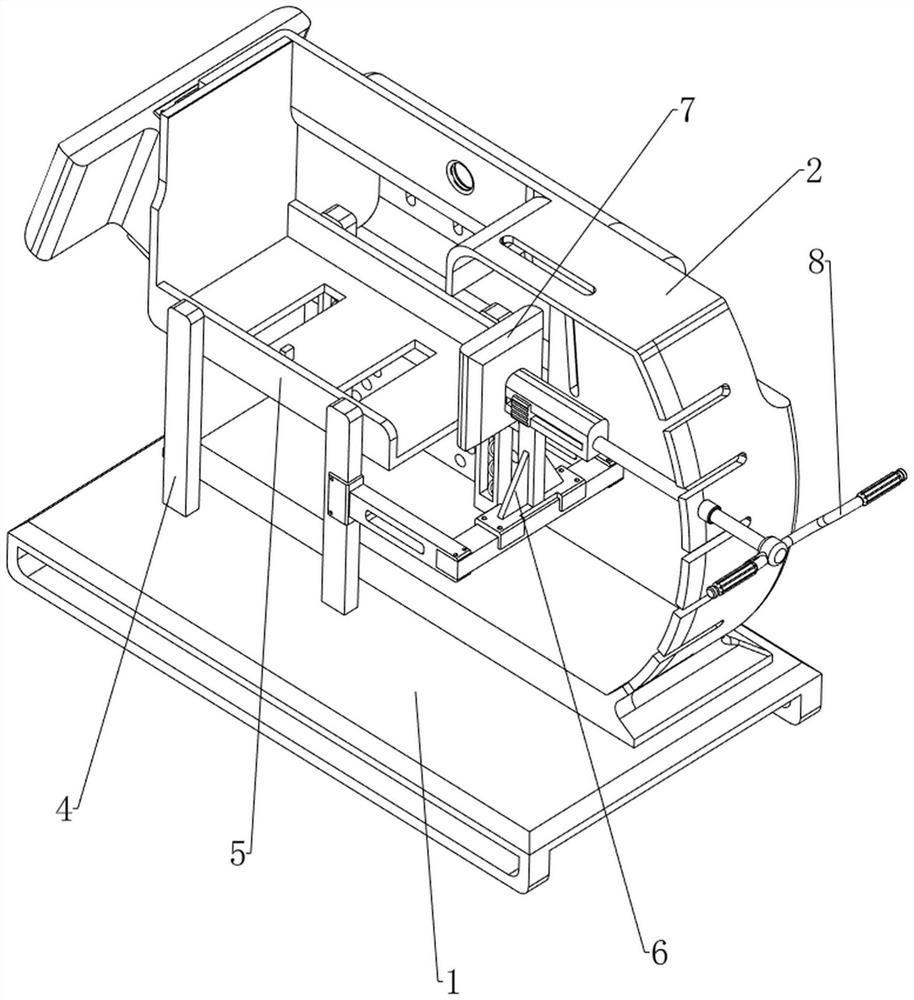

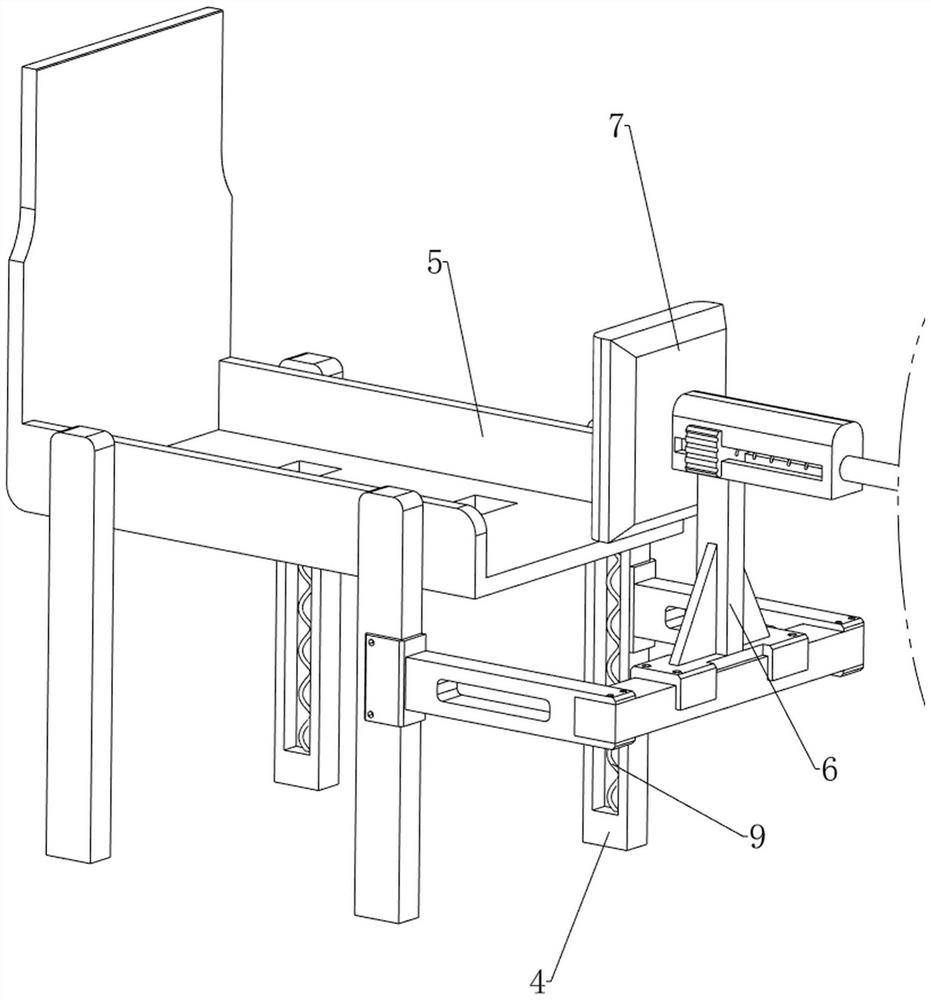

[0041] see Figure 1-Figure 20, the present invention provides a technical solution: a brand printing equipment for relay manufacturing, including a base 1, a frame body 2, a slide rail 4, a slide plate 5, a slide block 6, a first extrusion block 7, a push rod 8. The first spring 9, the second spring 10 and the clamping mechanism 11, the frame body 2 is welded on the base 1, two slide rails 4 are welded on the left and right sides of the inner wall of the frame body 2, and the upper sides of the four slide rails 4 The sliding plate 5 is connected between the two slide rails 4 on the rear side, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap