Steel bar connecting component and combination thereof

A technology for connecting components and steel bars, which is applied to building components, structural elements, building reinforcements, etc., can solve problems such as easy damage, insufficient material strength, and high cost, so as to reduce the hidden danger of exposed ribs on the board surface and meet quality requirements , The effect of layer spacing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

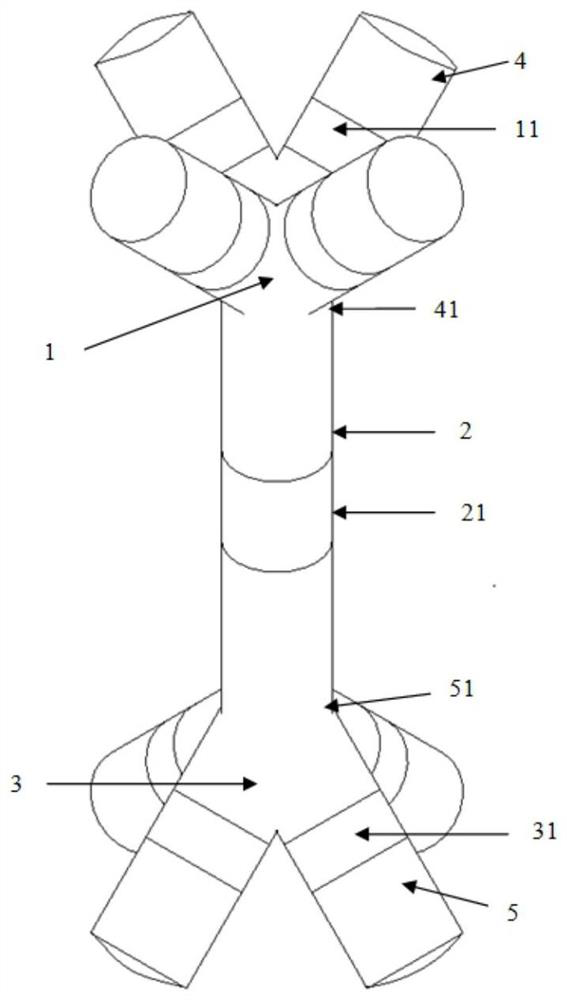

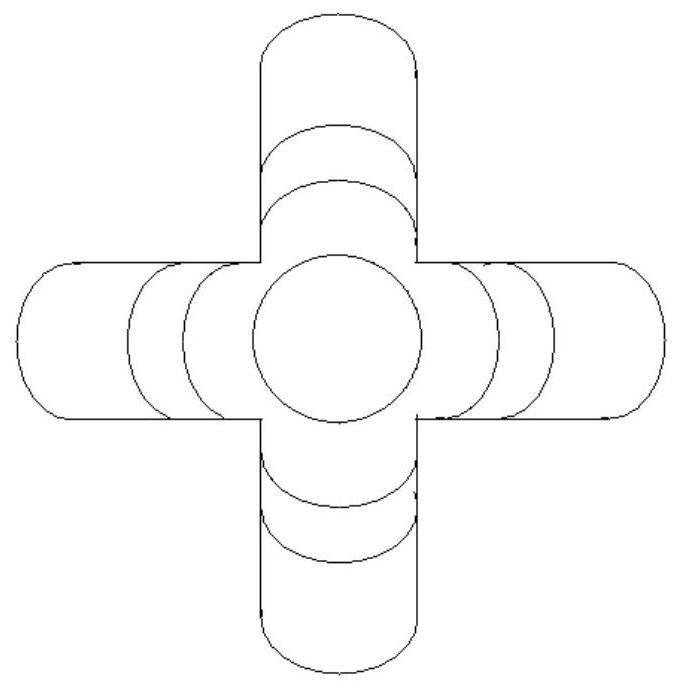

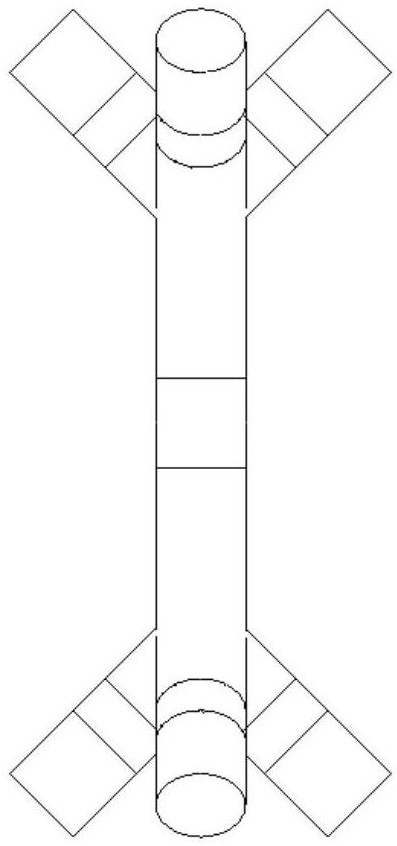

[0025] Such as Figure 1-3 As shown, a steel bar connection member according to the present invention includes a jacking 1 , a supporting column 2 and a base 3 . The top bracket 1 and the base 3 have the same structure, and are composed of four cylinders with the same structure. One end of the four cylinders with the same structure is connected as a whole to form a common circular end face. The four cylinders with the same structure The other ends extend along the direction with an angle of 45° to the horizontal plane, and a V-shaped groove is formed between two adjacent cylinders for placing steel bars; among them, the four cylinders with the same structure in the jacking 1 are four The first cylinder 4, the four cylinders with the same structure of the base 3 are four second cylinders 5, and one end of the four first cylinders 4 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com