Supporting method for soft rock roadway surrounding rock under high impact ground pressure stress

A compressive stress, high-impact technology, applied in underground chambers, tunnels, earth-moving drilling, etc., can solve the problems of small crack opening, long waiting time, and difficult on-site operation, so as to improve the porosity. , easy to reuse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

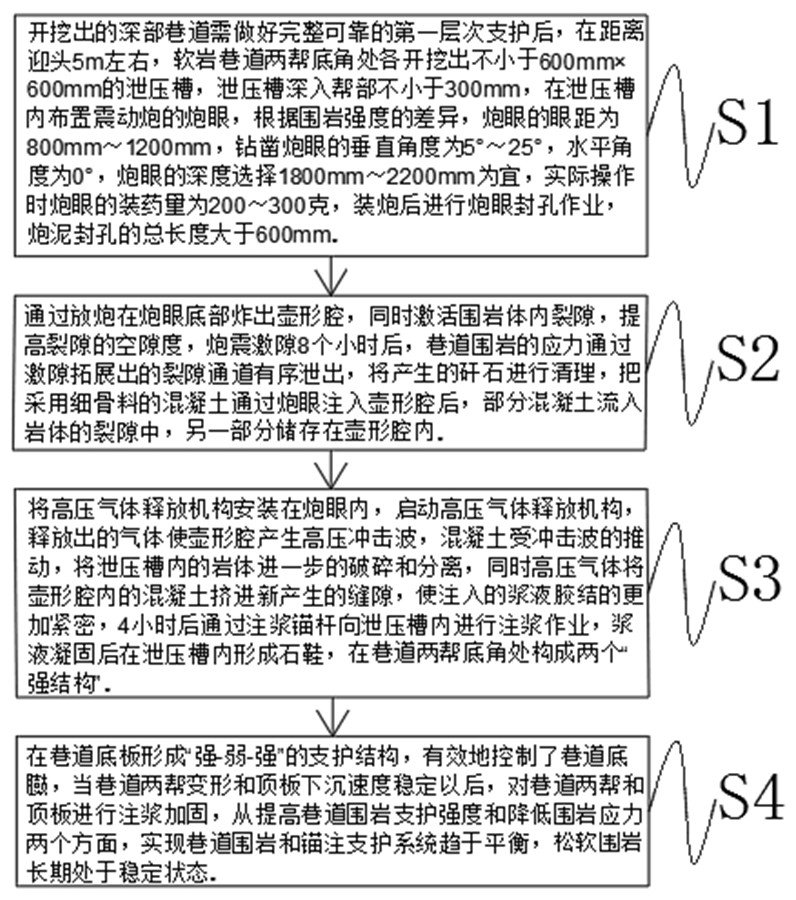

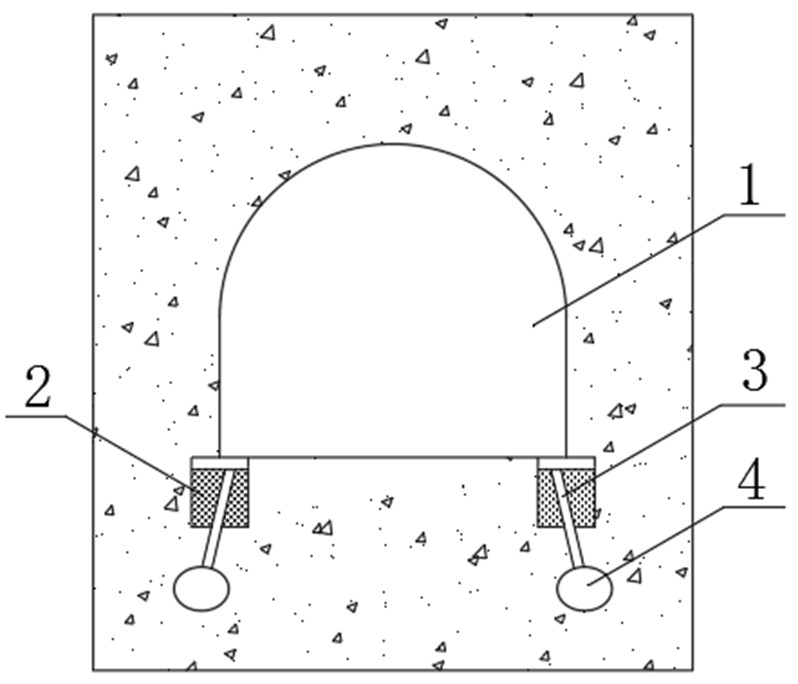

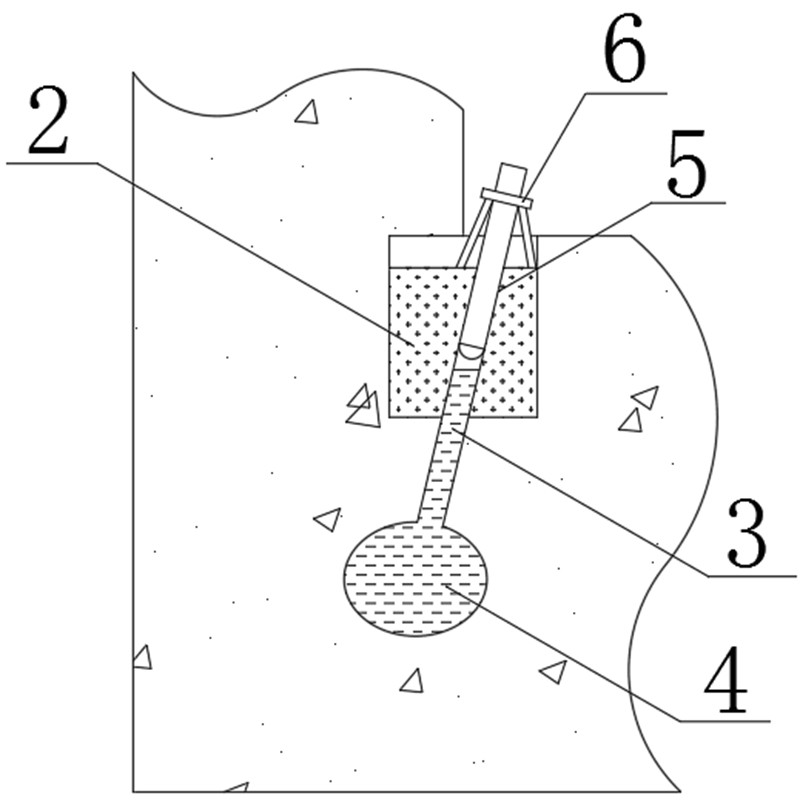

[0032] like Figure 1-5 As shown, a support method for the surrounding rock of soft rock roadway under high impact rock pressure stress, including the following steps:

[0033] A: After the excavated deep roadway (1) needs complete and reliable first-level support, at a distance of about 5m from the front, the bottom corners of the two sides of the soft rock roadway (1) should be excavated not less than 600mm×600mm The pressure relief groove (2), the depth of the pressure relief groove (2) to the side is not less than 300mm, and the blast hole (3) of the vibration gun is arranged in the pressure relief groove (2). According to the difference in the strength of the surrounding rock, the blast hole (3) The distance between the holes is 800mm~1200mm, the vertical angle of drilling the blasthole (3) is 5°~25°, the horizontal angle is 0°, and the depth of the blasthole (3) is preferably 1800mm~2200mm. The charge amount of the gun is 200 to 300 grams, and the blast hole (3) is seal...

Embodiment 2

[0041] like Figure 1-5 As shown, a support method for the surrounding rock of soft rock roadway under high impact rock pressure stress, including the following steps:

[0042] A: After the excavated deep roadway (1) needs complete and reliable first-level support, at a distance of about 5m from the front, the bottom corners of the two sides of the soft rock roadway (1) should be excavated not less than 600mm×600mm The pressure relief groove (2), the depth of the pressure relief groove (2) to the side is not less than 300mm, and the blast hole (3) of the vibration gun is arranged in the pressure relief groove (2). According to the difference in the strength of the surrounding rock, the blast hole (3) The distance between the holes is 800mm~1200mm, the vertical angle of drilling the blasthole (3) is 5°~25°, the horizontal angle is 0°, and the depth of the blasthole (3) is preferably 1800mm~2200mm. The powder charge is 200-300 grams. After the gun is loaded, the blasthole (3) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com