Material-saving narrow-edge air port

A narrow edge and air outlet technology, applied in the field of air conditioning structure, can solve the problems of only function, lack of aesthetics, labor and materials, etc., and achieve the effect of beautifying the appearance, saving materials, and technological progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

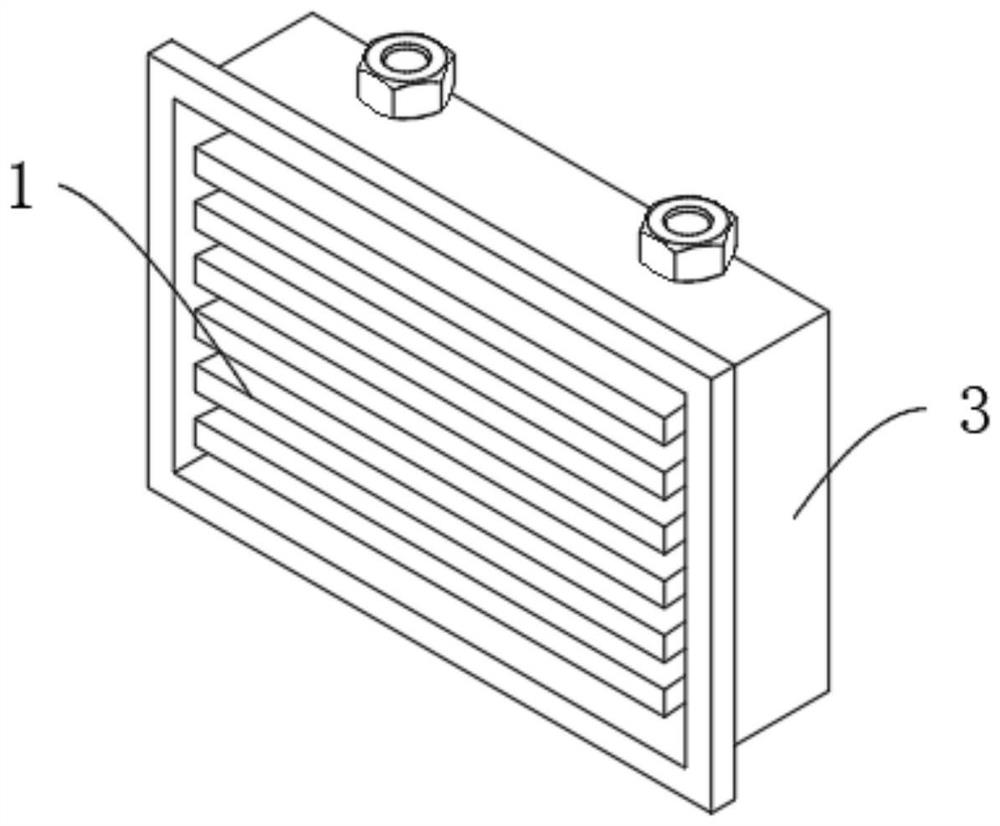

[0018] Example 1, please refer to Figure 1-2 , a material-saving narrow-side tuyere, comprising a louver 1, one end of the louver 1 is fixedly mounted with a connecting rod 2, and both ends of the connecting rod 2 are fixed with a frame piece 3 having the same size as the louver, and the frame One end of sheet 3 is set as the edge of the reinforced frame, and screw holes are provided inside the edge, and the edge and connecting rod 2 are fixedly installed. There are four frame sheets 3, and the four frame sheets 3 are welded end to end to form a side frame, and the louvers 1 There are several, several louver blades 1 are equally spaced, one end of the louver blade 1 is provided with a notch matching the connecting rod 2, there are two connecting rods 2, and the two connecting rods 2 are symmetrically distributed on the louver blade 1 Design the frame sheet 3 to be the same size as the louvers at both ends of the frame, and strengthen the frame by folding the structure on the ...

Embodiment 2

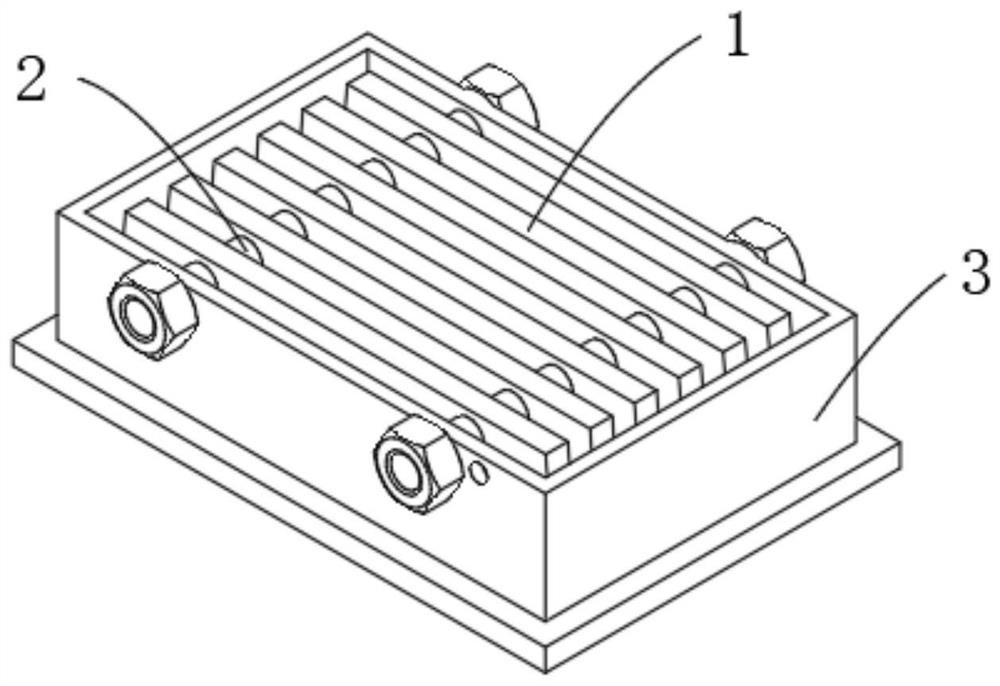

[0020] Embodiment two, such as image 3 , a material-saving narrow-side tuyere, including a louver 1, one end of the louver 1 is fixedly installed with a connecting rod 2, the louver 1 is set in a cone structure, and the two ends of the connecting rod 2 are fixed with a louver and a louver A frame piece 3 with the same size at one end of the blade cone, one end of the frame piece 3 is set as a folded edge of a reinforced frame, and screw holes are provided inside the folded edge, and the folded edge and the connecting rod 2 are fixedly installed, and the frame piece 3 has Four, four frame pieces 3 are welded end to end to form a side frame, there are several louver blades 1, and several louver blades 1 are equally spaced, and the small end of the louver blade 1 is provided with a notch matching the connecting rod 2, There are two connecting rods 2, and the two connecting rods 2 are symmetrically distributed at both ends of the louver 1, and the frame piece 3 is designed to be ...

Embodiment 3

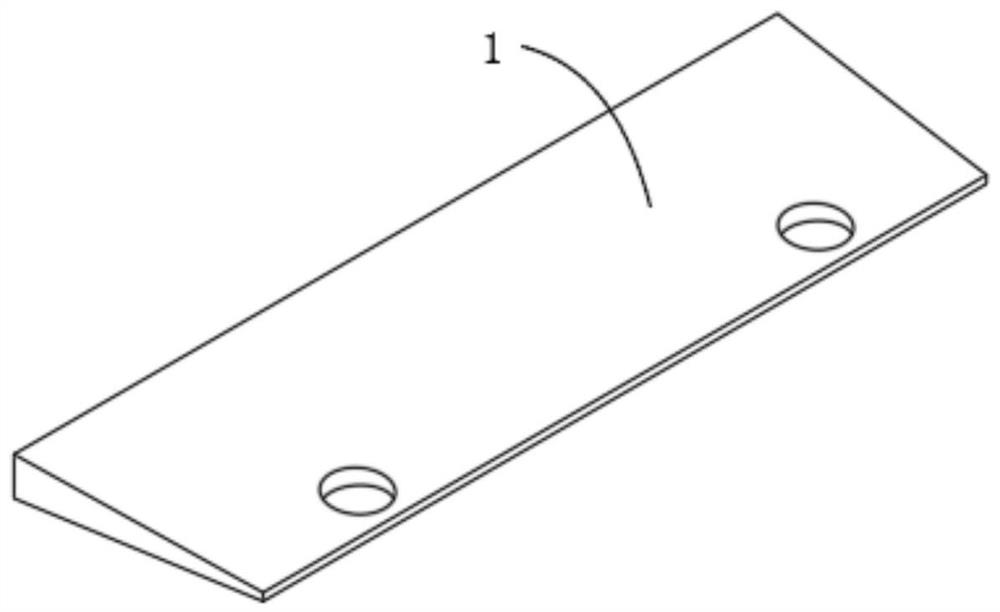

[0022] Embodiment three, such as Figure 4 , a material-saving narrow-side tuyere, comprising a louver 1, one end of the louver 1 is fixedly mounted with a connecting rod 2, and both ends of the connecting rod 2 are fixed with a frame piece 3 having the same size as the louver, and the frame One end of the sheet 3 is set as the edge of the reinforced frame, the inside of the edge is provided with a screw hole, the edge and the connecting rod 2 are fixedly installed, there are four frame sheets 3, and the two frame sheets 3 are folded in half so that the two folded The width of the frame sheet 3 is 1 / 4 of the width of the normal frame sheet 3, and the two frame sheets that are folded in half are welded to the two ends of the two frame sheets that are not folded in half, so that the two frame sheets 3 that are not folded in half are parallel up and down. The four frame pieces are welded into a side frame, and the louver 1 is installed inside the side frame so that the louver 1 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com