A mems thermal microphone and its implementation method

A microphone and substrate technology, which is applied in the field of microelectronic mechanical sensing, can solve the problems of phase difference between sound pressure and vibration velocity signals, different manufacturing processes, and inability to ensure the common point of the sound center, so as to eliminate harmonic distortion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

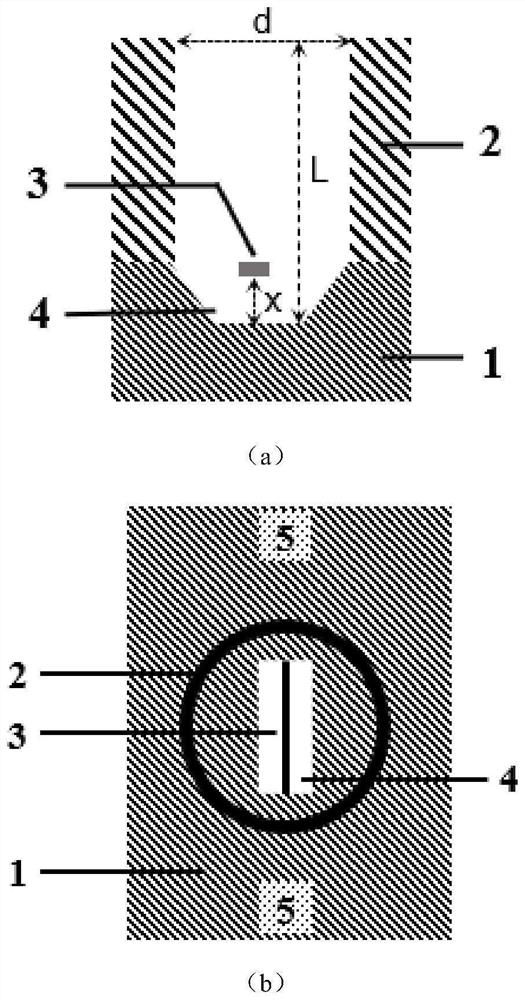

[0050] Such as figure 1 As shown, the upper cover plate of this embodiment adopts a cylindrical shape, and the MEMS thermal microphone of this embodiment includes: a substrate 1, a sensitive beam 3, an electrode 5, a back cavity 4, an upper cover plate 2 and a temperature measuring circuit; wherein, The substrate is made of hard material; a back cavity is set on the upper surface of the substrate; the two ends of the sensitive beam are erected on the edge of the back cavity on the upper surface of the substrate, and the sensitive area of the sensitive beam is located on the back cavity; on the upper surface of the substrate Two electrodes are set on the part without the back cavity; the two ends of the sensitive beam are respectively connected to an electrode, and the two electrodes are connected to the external temperature measuring circuit; an upper cover is arranged on the back cavity on the upper surface of the substrate, and the upper cover The inner surface of the inne...

Embodiment 2

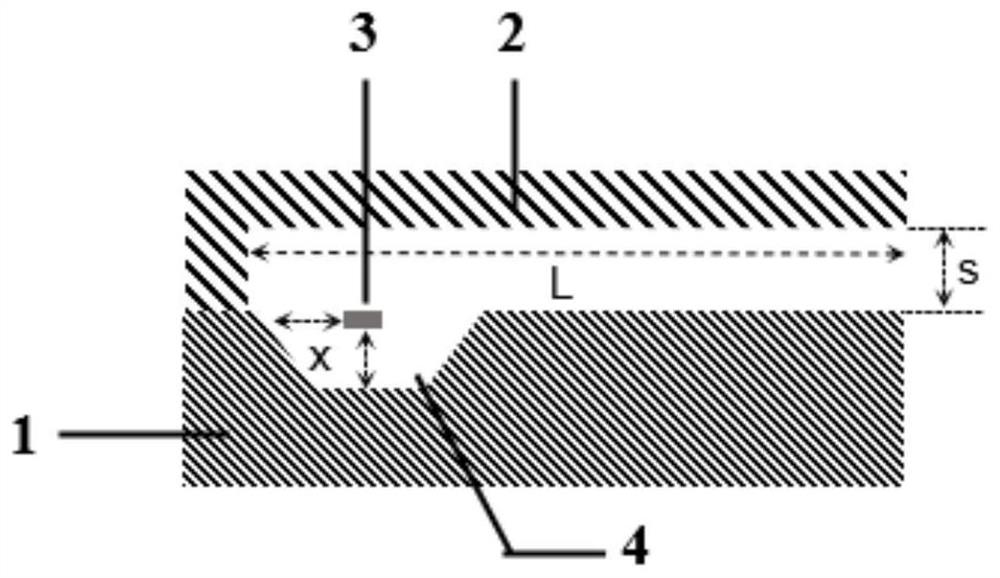

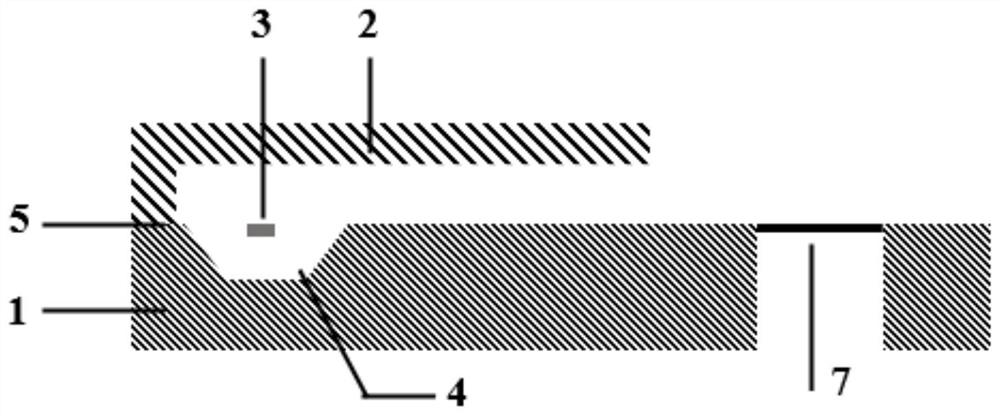

[0052] Such as figure 2 As shown, the upper cover plate of this embodiment adopts a cover shape, and one side of the cover-shaped upper cover plate is located at the outer edge of the back cavity and is sealingly connected with the upper surface of the substrate. Above and parallel to the upper surface of the substrate, the other side has a distance from the upper surface of the substrate to form an opening, as the nozzle of the standing wave tube, the distance s between the inner surface of the top wall and the upper surface of the substrate is less than 8.5mm. The upper cover adopts a cover shape, the bottom surface of the back cavity and the side surface facing the nozzle of the standing wave tube both constitute the tube bottom of the standing wave tube, the distance between the sensitive beam and the bottom surface of the back cavity and the distance between the sensitive beam and the back cavity The distance between the side surface of the nozzle of the standing wave t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com