Metal powder paving device for 3D dual-laser metal printer

A dual-laser technology for printers, applied in the direction of process efficiency improvement, energy efficiency improvement, additive processing, etc., can solve problems such as uneven distribution of metal powder, lower paving quality, etc., and achieve the effect of high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

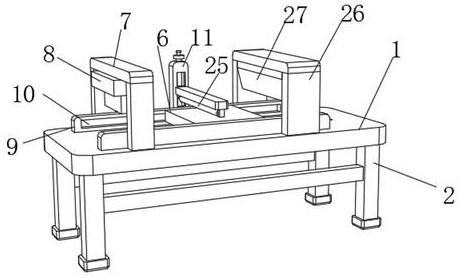

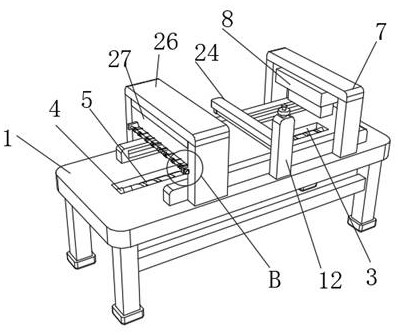

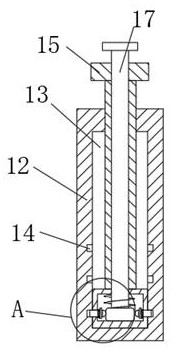

[0028] Such as Figure 1-6As shown, the embodiment of the present invention provides a metal powder paving device for a 3D dual laser metal printer, including a table top 1 and a paving assembly 11, and the paving assembly 11 includes a vertical block 12, and the inside of the vertical block 12 is provided with a second limiting groove 13. The inner walls of the left and right sides of the second limiting groove 13 are provided with card slots 14, the inside of the second limiting groove 13 is slidably connected with a column 15, and the lower end of the column 15 is fixedly connected with a second fixed block 16, and the bottom of the column 15 A sliding column 17 is slidably connected in the inner through hole, and a third limiting groove 19 is arranged inside the second fixed block 16. The lower end of the sliding column 17 runs through the second fixing block 16 to the third limiting groove 19 and is fixedly connected with a The push block 18 and the sliding column 17 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com