Bearing unit with eccentric clamping collar

A technology for eccentric collars and bearings, which is applied to bearing elements, bearings for rotational motion, bearings, etc., and can solve problems such as complicated machining of radial inner rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

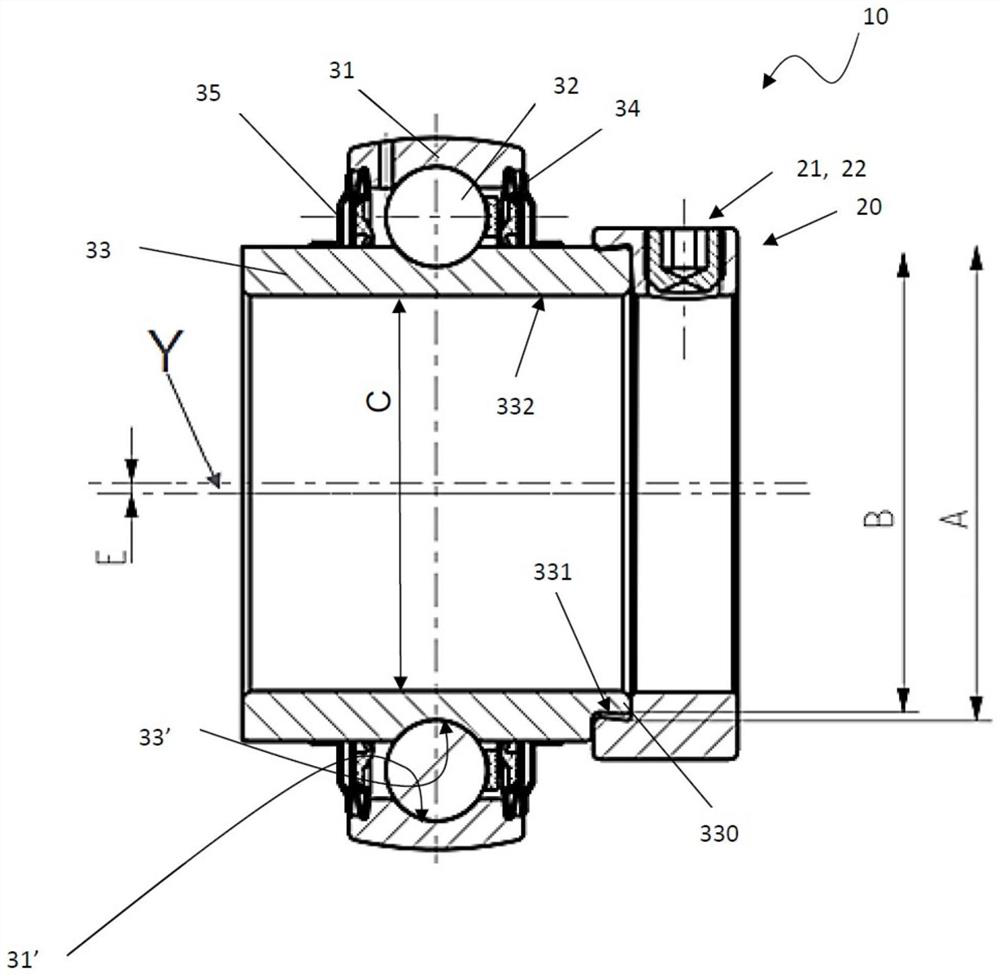

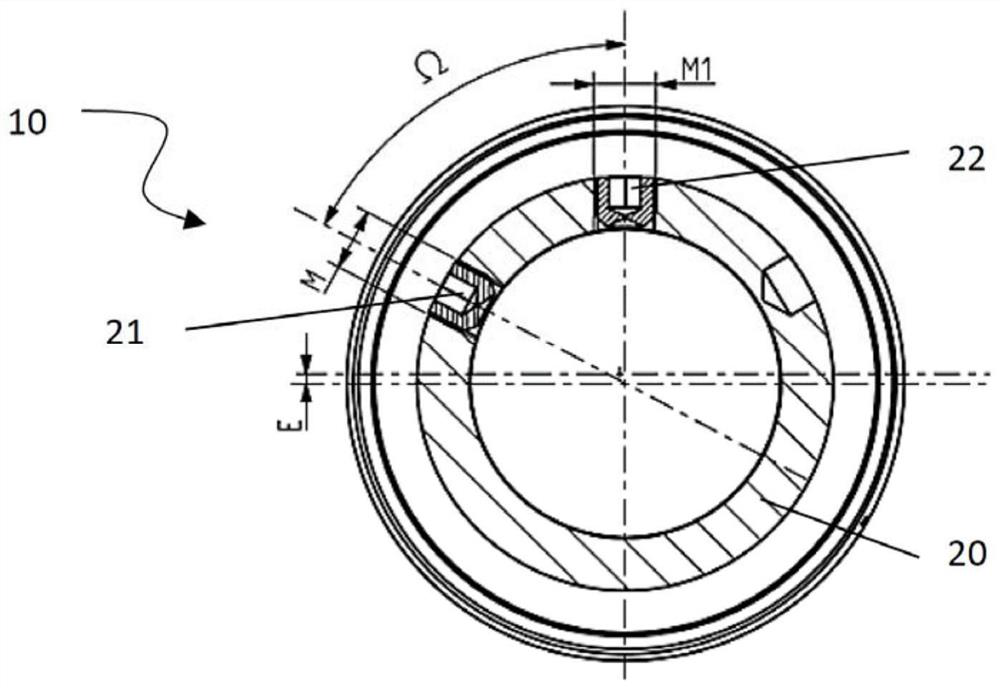

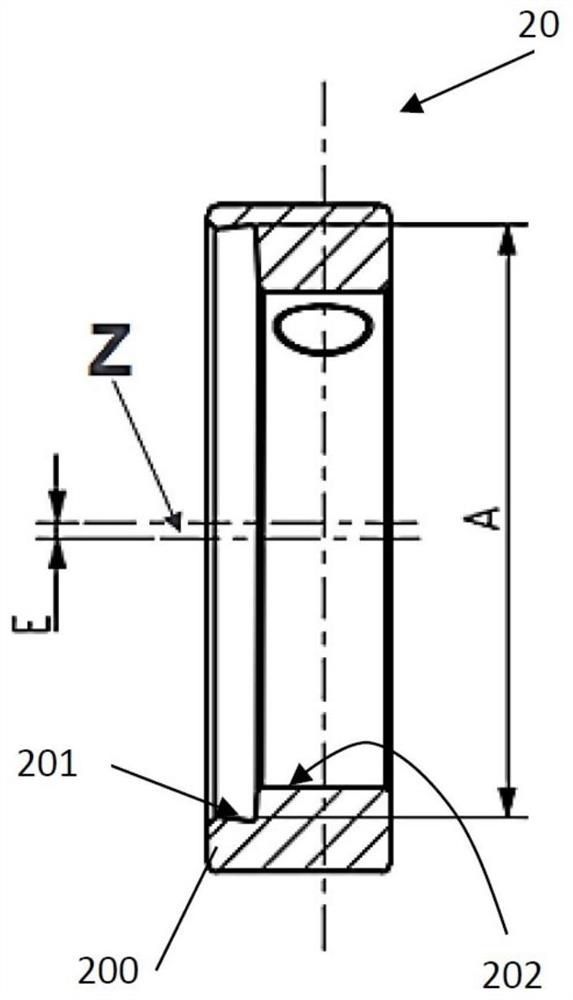

[0020] Embodiments of the bearing unit according to the present invention are described below by way of example only with reference to the above-mentioned drawings.

[0021] special reference figure 1 , the bearing unit 10 for applications in the agricultural field and / or in the manufacturing industry (for example, textile, mining, motor vehicle or food industry) can be, for example, between the rotating shaft and the housing element, in the rotating shaft and the housing element Each of which does not form part of the present invention, and the bearing unit 10 comprises:

[0022] - fixed ( / stationary) (stationary) radially outer ring 31,

[0023] - a radially inner ring 33 rotatable about the central axis of rotation Y of the bearing unit 10,

[0024] - at least one row of rolling elements 32, between the radially outer ring 31 and the radially inner ring 33, in this example rolling elements 32 being balls,

[0025] - a cage 34 for accommodating the rolling bodies to hold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com